Section 5 – PERIODIC MAINTENANCE

Mini-Crawler Crane M A E D A

5-42 3/2019 MC305C-3

8. Turn the filter cartridge (3) counterclockwise

(left) with the use of the filter wrench to

remove it.

NOTICE: The oil is to be drained in large quantity

immediately after the engine is stopped. Wait for

10 minutes before removing the filter cartridge (3).

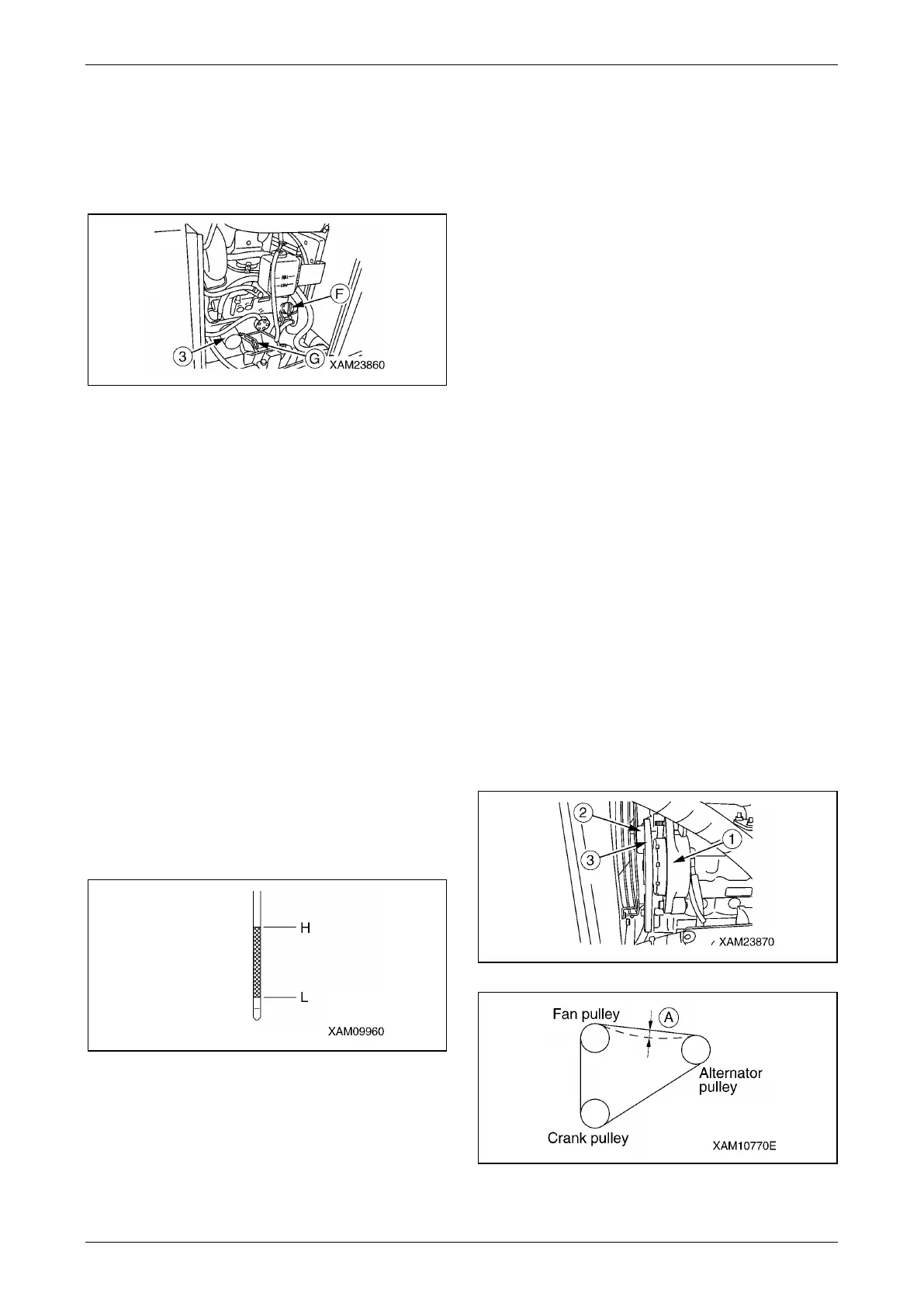

Fig. 5-64

9. Clean the filter stand. Apply clean engine oil

(or a light coating of grease) to a new filter

cartridge gasket and thread part, and install

the filter cartridge.

NOTICE: With the gasket surface maintained

contact with the sealing surface of the filter stand,

rotate the filter cartridge one-half to three-quarters

of a turn to secure it.

Always give manual tightening to the filter

cartridge.

10. Check around the filter cartridge (3) for oil

leaks. Be sure to wipe off oil completely if

spilled.

11. After replacing the filter cartridge (3), supply

the engine oil at a specified amount from the

filler cap (F).

12. With the oil level gauge (G) pulled out, wipe

off the oil with a waste cloth.

13. With the oil level gauge (G) inserted in the

gauge guide, pull the oil level gauge out.

14. Make sure the oil level is in the range "H" to

"L" marked on the oil level gauge (G).

Fig. 5-65

15. Attach the oil level gauge (G) and filler cap (F)

properly upon completion of oil replacement.

16. Start the engine, and idle it for 5 minutes.

Stop the engine.

17. Make sure again the oil level is in the range

"H" to "L" marked on the oil level gauge (G).

18. See "Installing Machinery Cover" on page

5-18 and install the machinery cover.

19. See "OUTRIGGER STOWING" on page 4-45

and stow the outriggers.

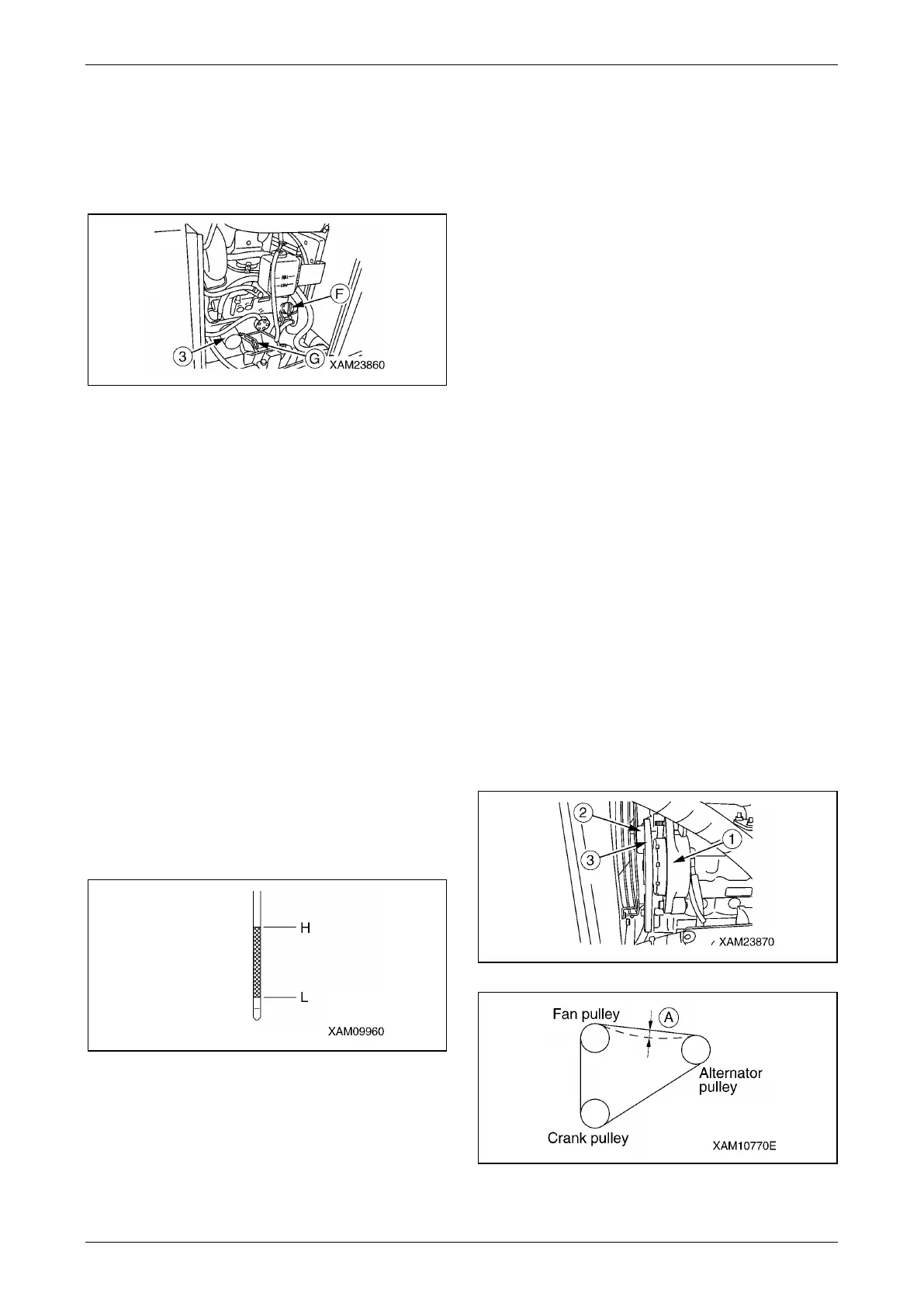

Check / Adjust Belt Tension

Tension Check

1. See "OUTRIGGER SETTING" on page 4-36

and rotate the outriggers outward.

2. See "Removing Machinery Cover" on page

5-18 and remove the machinery cover.

3. With the fingers, push (by approximately 98 N

(10 kgf) the midpoint between the fan pulley

(2) and alternator pulley (1) of the belt (3),

and if the strain is between 10 and 12mm it is

within standard.

4. If the inspection result indicated that the

strain of the belt (3) is out of the standard

value range, see the Tension check section

and adjust the tension of the belt (3).

NOTICE: Inspect the followings as well when you

inspect the tension of the alternator belt.

• Check the pulleys for breakage, the V groove

and belt for wear. Ensure that the belt is not in

contact with the bottom of the V groove.

• Prompt belt replacement is required if belt

adjustment is no longer enabled due to a

stretched belt or if the belt is scratched or

cracked.

• At least 5 minute long test run is required after

belt replacement. Re-adjust the belt tension

upon completion of test run.

Fig. 5-66

Fig. 5-67

Loading...

Loading...