Section 5 – PERIODIC MAINTENANCE

Mini-Crawler Crane M A E D A

5-44 3/2019 MC305C-3

Inspect / Clean / Replace Air Cleaner

WARNING!

• DO NOT clean and replace the air cleaner

when the engine is in rotation.

Potential damage to the engine may occur if

disregarded.

• Use of compressed air when cleaning the

element causes particles to be airborne.

Always wear protective goggles to prevent

injury from flying particles.

CAUTION:

• Assure pre- or post-work cleaning when

using the machine in a dusty site.

• DO NOT tap and bump the element against

anywhere when cleaning it.

• Avoid the use of an element if its groove,

gasket, or sealing is damaged.

• Always use Maeda genuine elements.

1. See "OUTRIGGER SETTING" on page 4-36

and rotate the outriggers outward.

2. See "Removing Machinery Cover" on page

5-18 and remove the machinery cover.

3. Disengage the two clamps (1) and remove

the dust pan (2).

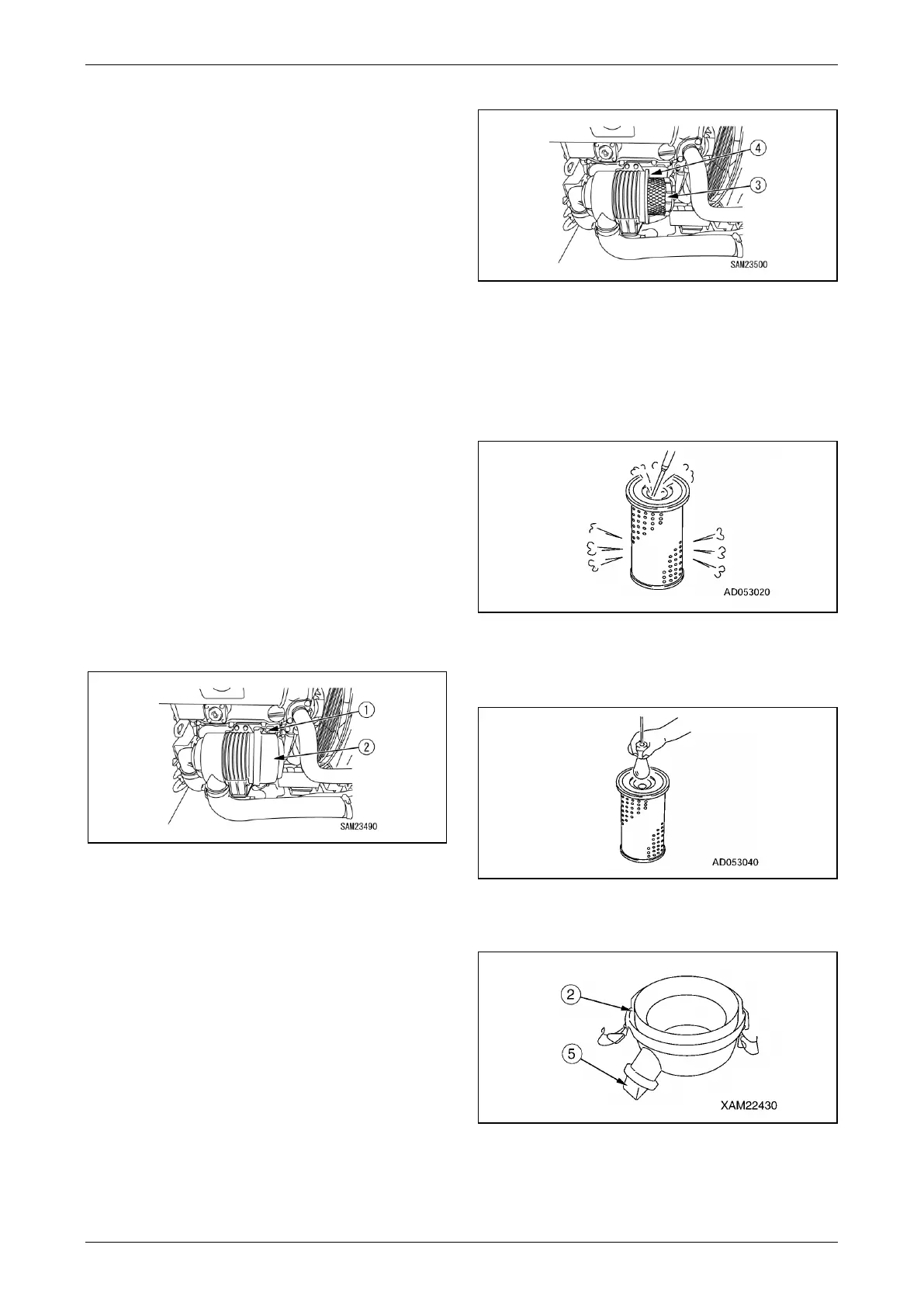

Fig. 5-70

4. Pull out the element (3).

5. Cover the duct entrance located at the back

of the air cleaner body (4) with a clean cloth

or tape, to keep impurities out of the duct

entrance.

6. Clean the inside of the air cleaner body (4).

Fig. 5-71

7. Blow dry compressed air on the inside of the

element along the grooves at max. 0.69MPa

(7kg/cm

2

).

Blow compressed air on the outside of the

element along the grooves, and re-blow the

air on the inside.

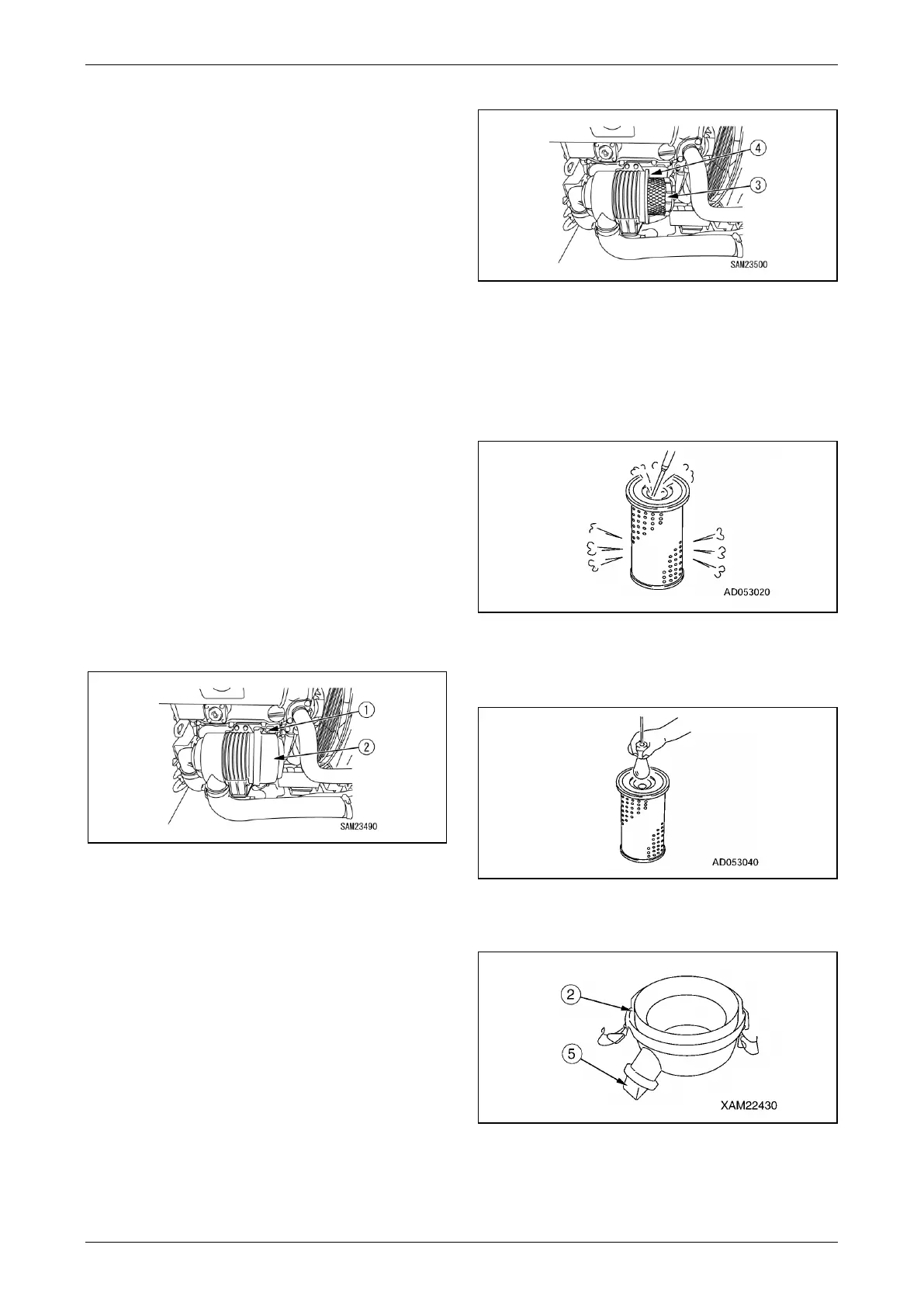

Fig. 5-72

8. Shine a light bulb into the element after

cleaning for check. If check finds a pore or

thinned part, replace the element.

Fig. 5-73

9. Clean the inside of the dust pan (2) and

rubber cup (5).

Fig. 5-74

10. Remove the cloth or tape from the air

connector at the back of the air cleaner body

(4).

Loading...

Loading...