M A E D A Mini-Crawler Crane Section 5 – PERIODIC MAINTENANCE

3/2019 MC305C-3 5-49

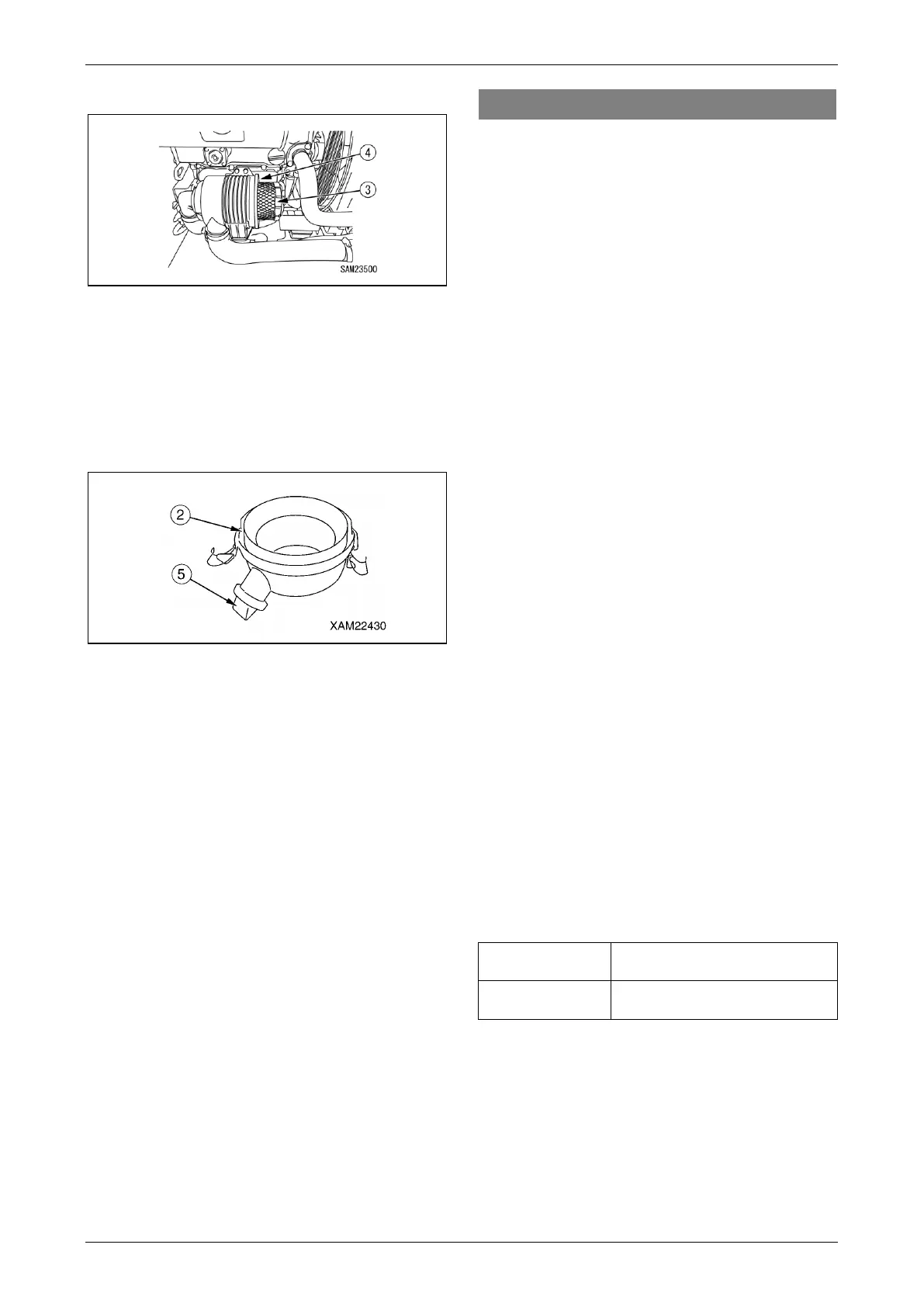

4. Pull out the element (3).

Fig. 5-83

5. Cover the duct entrance located at the back

of the air cleaner body (4) with a clean cloth

or tape, to keep impurities out of the duct

entrance.

6. Clean the inside of the air cleaner body (4).

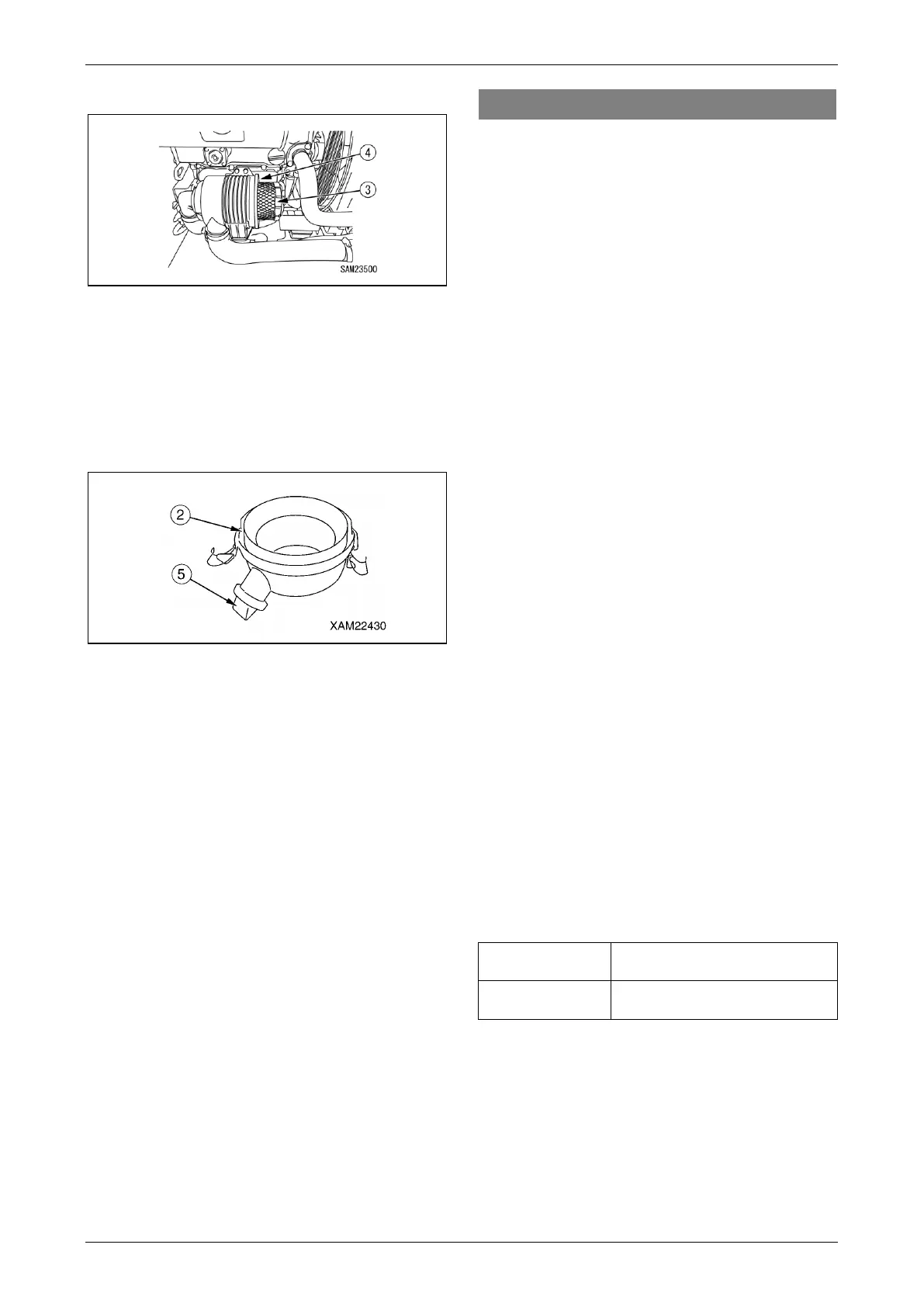

7. Clean the inside of the dust pan (2) and

rubber cup (5).

Fig. 5-84

8. Remove the cloth or tape from the air

connector at the back of the air cleaner body

(4).

9. Insert a new element (3) into the air cleaner

body (4).

10. Install the dust pan (2) to the air cleaner body

(4) with a "TOP" mark faced upward, and

secure it with the two clamps (1).

11. See "Installing Machinery Cover" on page

5-19 and install the machinery cover.

12. See "OUTRIGGER STOWING" on page 4-45

and rotate the outriggers inward to stow

them.

Maintenance Every 1000 Hours

Coolant Replacement and Internal

Cleaning

WARNING!

• Coolant will be at elevated temperatures

immediately after engine operation, which

urges you not to drain coolant. Always

perform coolant draining with the engine

cold.

• DO NOT remove the radiator cap if radiator

coolant is hot. Potential gush of boiling

water may occur if disregarded. Cap removal

is allowed when the water drops in

temperature. Be sure to relieve internal

pressure by slowly rotating the filler cap

before cap removal.

• DO NOT stand in front of and behind the

machine when starting the engine for

cooling system cleaning. Failure to stand

aside of the machine may pose a danger in

the event of a sudden movement of the

machine.

• Keep antifreeze from flame. Antifreeze is a

flammable solution.

DO NOT smoke when handling antifreeze.

CAUTION:

• Always use tap water for coolant. Contact Us

or our sales service agency if river water,

well water, or water through the small

water-supply system is necessarily

substituted for tap water.

• A mixing ratio of antifreeze is to be

controlled by the concentration meter.

Cooling system cleaning and antifreeze

replacement should conform to the cycles

specified in the following table.

Cooling system cleaning and

antifreeze replacement

Anti-corrosive

all-season type

Annually or every 1000 hours

Perform cooling system cleaning and antifreeze

replacement with the machine in a horizontal

position.

A mixing ratio of antifreeze varies with

temperature. Antifreeze as a volume ratio is min.

30% to yield anticorrosive effect.

Loading...

Loading...