– 2.2 –

2-1. Explanation of electrical components

2-1-1. Operations

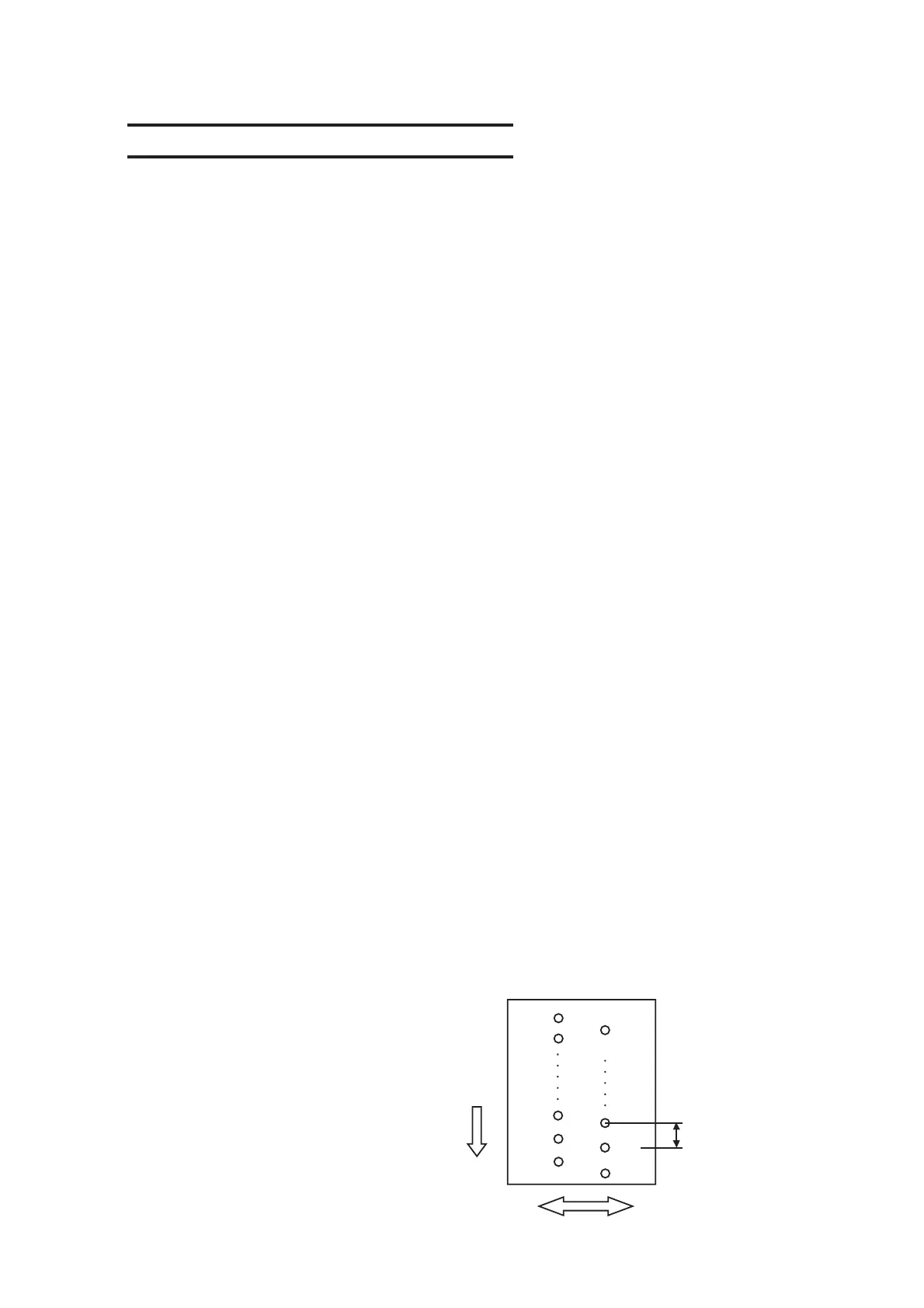

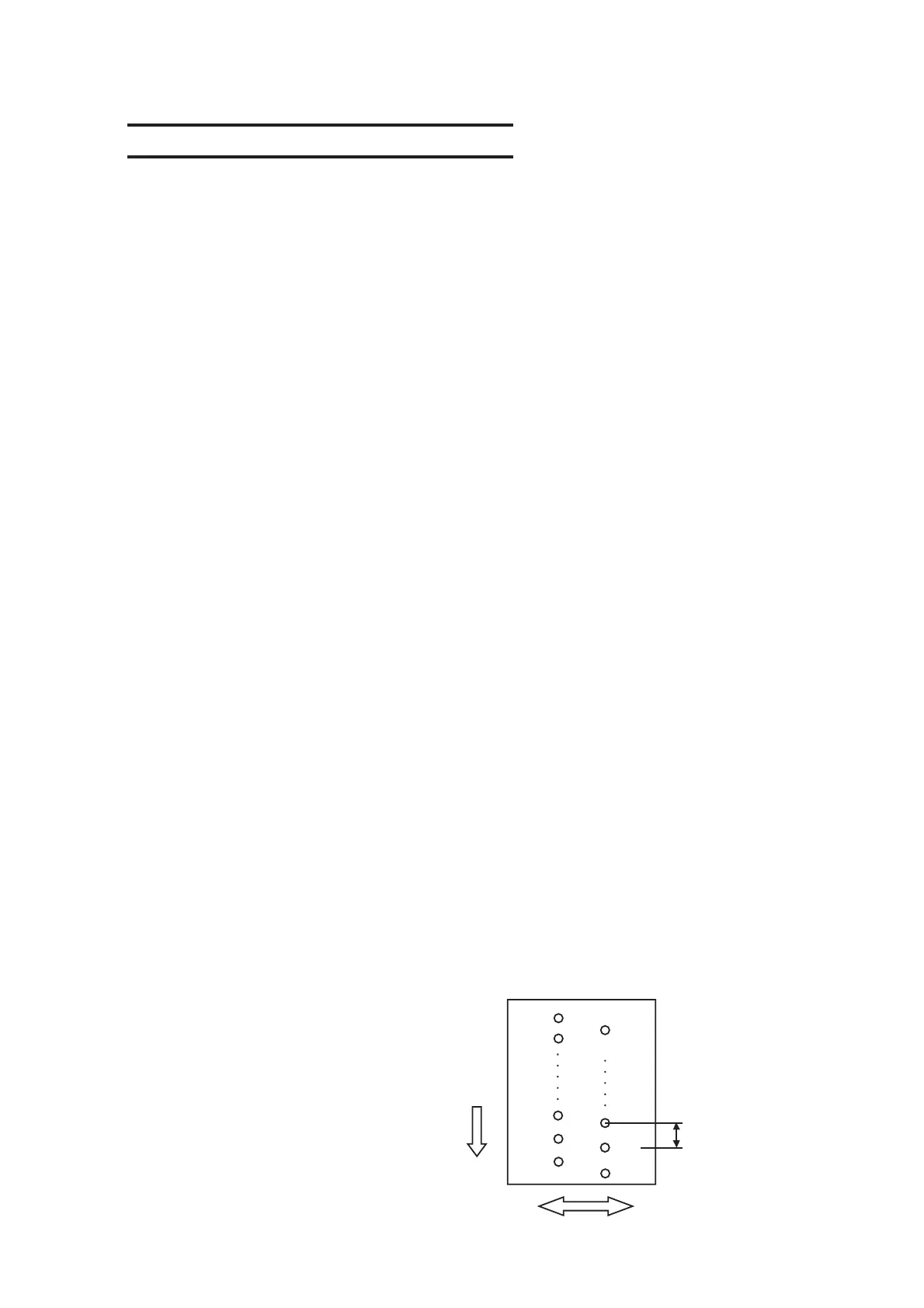

*The slider of the JV3-75SPII/130SPII/130SL/160SP is provided with four heads with inline

arrangement, with 180 nozzles (at 180dpi intervals) x 2 rows (2 colors) for each head. JV3-130SL

sets 2 heads in line.

* The ink in the ink chamber is discharged by vibrating the piezo-electric element of the head. The JV4

uses four different vibration waveform modes: the V1 (Variable1) mode which enables four gradations

(without L, M, and S) with 360 dpi resolution, the V2 (Variable2) mode which enables four gradations

with smaller dots with 720 dpi resolution, the N1 (Normal1) mode which enables high-speed two

gradations (1.0) with 360 dpi resolution, and the N2 (Normal2) mode which enables high-speed two

gradations with 720 dpi resolution.

However, note that the Normal waveform modes are not used when normal data is received from the

host PC. (Some Variable waveforms are represented in two gradations.)

Since the driving frequency (or the scanning speed of the head) depends on each waveform, Y-directional

position adjustment is required for each waveform.

* The main PCB is provided with two FPGAs (HDCs) which generate the driving signal (COM wave-

form) to be applied to the piezo-electric element of one nozzle row for two heads. The COM waveform

is applied in synchronization with the scale interval of each linear scale and, at the same time, the nozzle

data is transferred to the head. Y-directional position adjustment can be made in units of one dot or less

by adjusting the timing of the COM waveform for each nozzle row.

Since the ink discharge performance depends on each head, the COM waveform is corrected automatically

based on the head ID registered and the ambient temperature detected. (If the head ID is not registered

correctly, no ink may be discharged.)

* The main PCB is provided with the FPGA (PDC) in charge of image processing to which the 128MB

DSRAM picture memory (PRAM) is connected. As for the data output from the host PC, the command

is analyzed by the CPU and the image is transferred to the memory through high-speed DMA. Since the

PRAM has the ring memory configuration, head scanning is started when data for each scanning has

been stored. Since only an image with 180 dpi resolution can be formed into the X direction in each

scanning, the image with the target resolution is completed while making required amount of paper

feed.

* Stepping motors, sensors, and many other IO devices are connected to the JV3. Therefore, if all of them

are connected directly to the main PCB, it becomes difficult to handle wires and replace the PCB. To

avoid this, the number of signals has been reduced through serial signal transmission with the main PCB

using IO PCBs. This signal processing is performed by the FPGA (PDC) mounted on the main PCB.

Scanning direction

180 dpi interval

Head nozzle arrangement

(viewed from rear side)

A#180

A#2

A#1

B#180

B#2

B#1

Paper feed

direction

Loading...

Loading...