– 1.3 –

1-2. How to use this maintenance manual

Use the maintenance manual in the following manner.

• Check first a phenomenon that is arising to grasp the trouble.

• Secondly, grasp the outline of the trouble while referring to error messages given in Chapter 3.

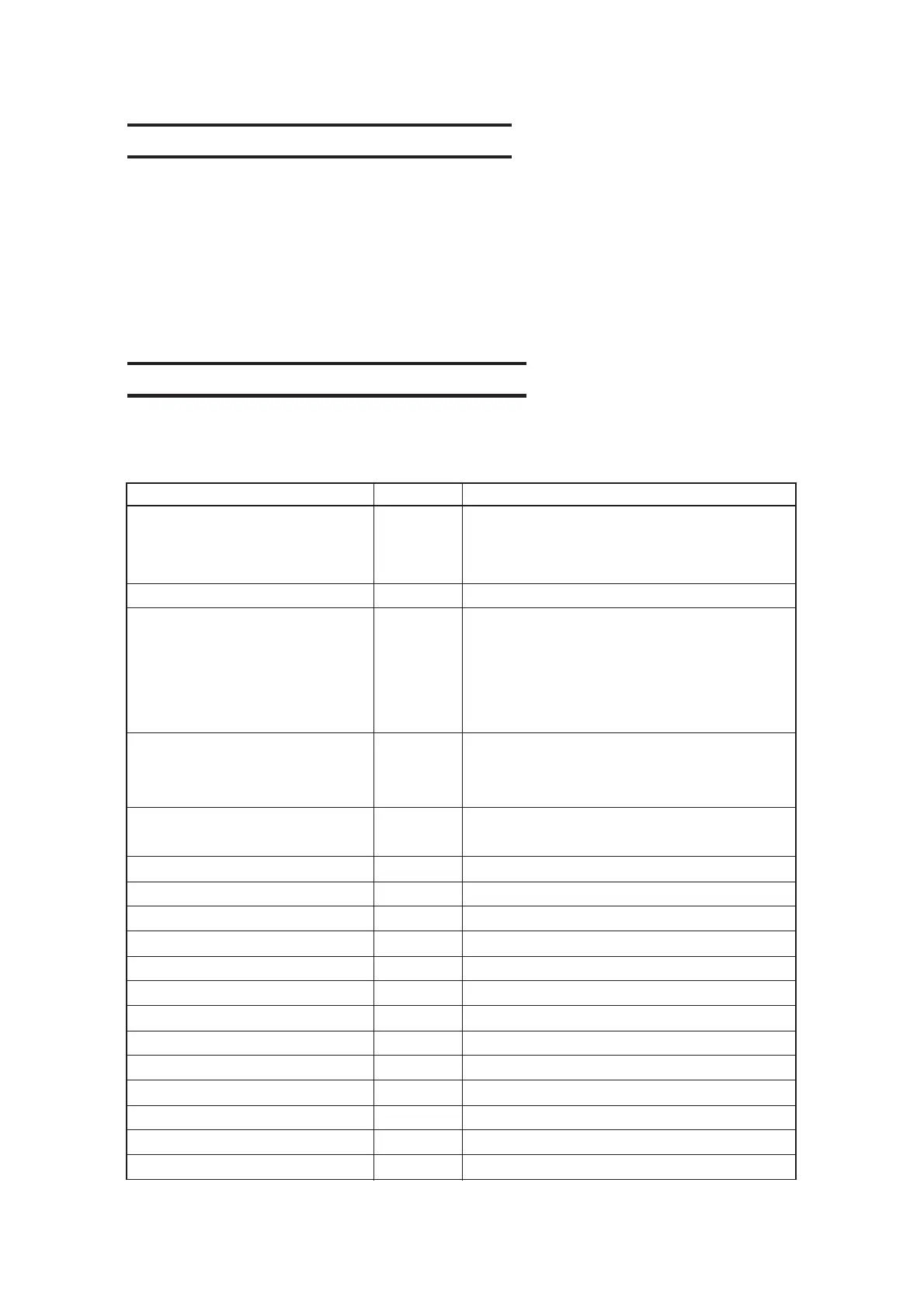

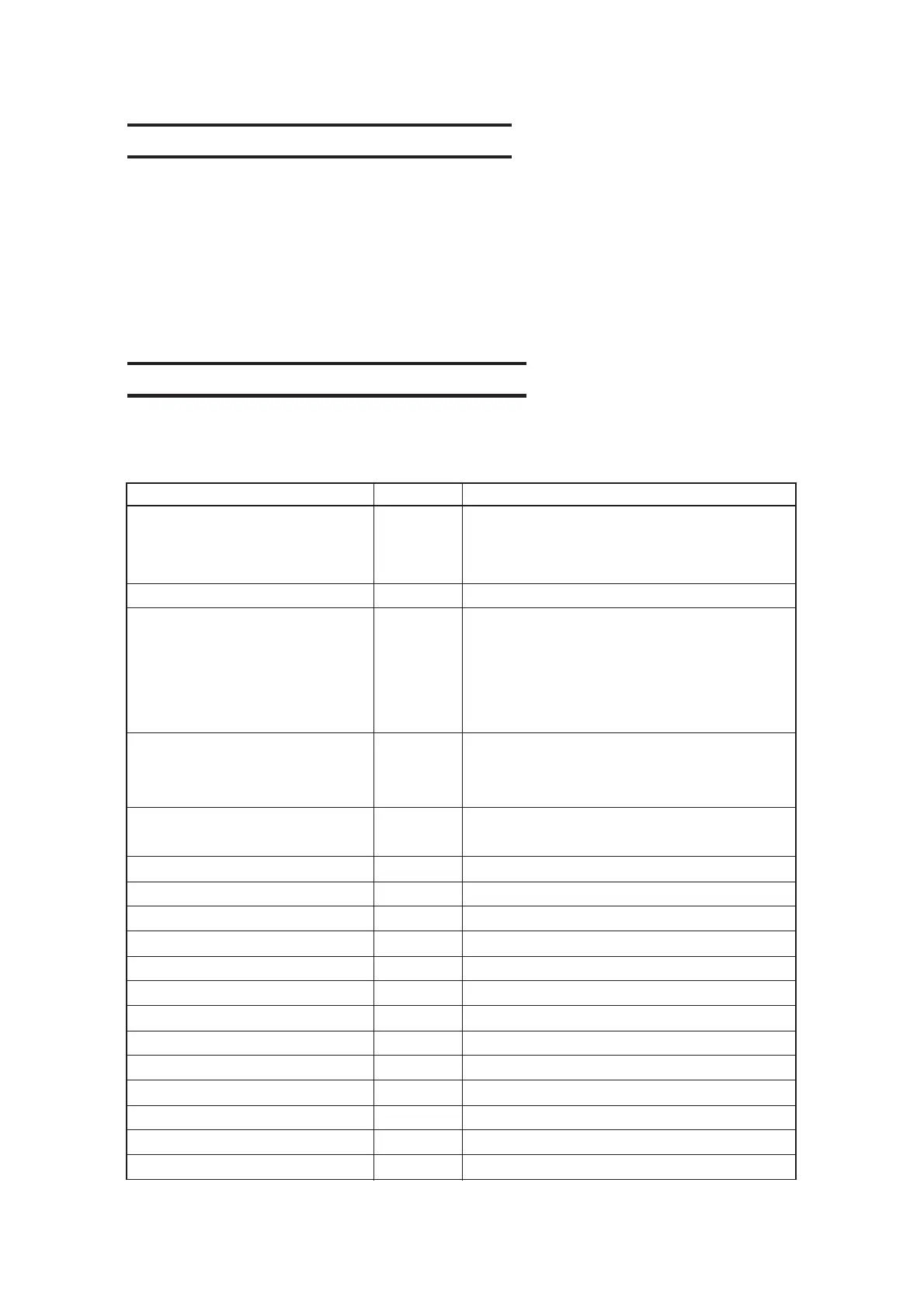

1-3. Tools required for maintenance works

Tools and measuring apparatus required for maintenance works are given below.

Name Q’ty Remarks

Phillips screwdriver, type 1 1 For M2

Phillips screwdriver, type 2 1 For M3 to M5 (L=260 or more)

Phillips screwdriver, type 2 1 For M3 to M5

Slotted screwdriver 1 Log side 2.5 mm for drawing out E-rings

Hexagon wrench key 1 1.5 mm for M3 SSWP

1 2.0 mm for M4 SSWP

1 2.5 mm for M3 cap bolts (L=170)

1 5.5 mm for hexagon stud

1 6.0 mm for M8 cap bolts

Wrench 1 Opposite side 5 mm

1 Opposite side 5.5 mm for M3 nuts

1 Opposite side 7 mm for M4 nuts

Tweezers 1 To prevent the cable from being pulled when

disconnecting the connector

Long-nose pliers 1

Nippers 1

Soldering iron 1

Scale 1 500 mm, 150 mm

Bar-type tension gauge 1 For 500 gf

Tester 1 If necessary

Magnifier 1 Magnification of approx. 50 to 60

Adhesive agent 1 LOCKTITE242 (for locking screws)

Gloves 1 In prevention of stains and safeguarding

Insulation lock As required L=150 or less (UL-approved product)

Nitroflon tape or acetate fabric tape As required UL-approved product

Solder As required

Protection glasses 1

Loading...

Loading...