6-8

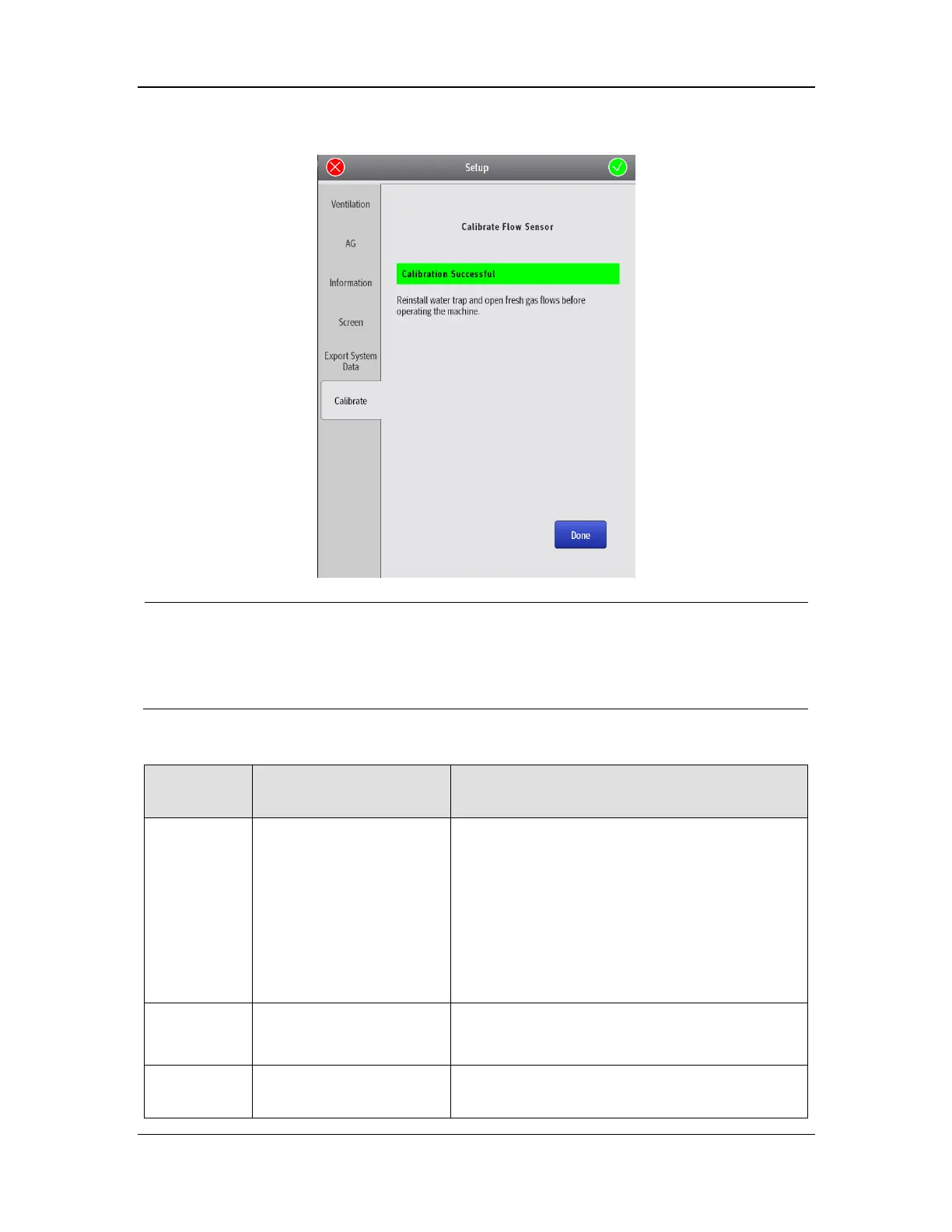

9. The screen shown below is displayed upon successful calibration. Select Done to exit the

calibration screen.

If measurement deviations are not corrected after multiple flow sensor

calibrations, it is recommended that a flow sensor in the circuit be replaced and

then a calibration be performed for the new flow sensor. If the problem persists,

send the machine to the manufacturer for maintenance. After the problem is fixed,

perform the calibration and system tests.

6.3.1.3 Common Failures and Recommended Actions

Failure

Description

Possible Cause Recommended Action

Display 1

insufficient.

1. Check whether the gas supply is sufficient for

the whole calibration process. (T

gas pressure is not less than 345 kPa (50 psi).)

2. F

low calibration should only be performed

using pipeline gas supply.

3. Check whether the maximum output flow of

the valve is greater than 60 L/min. If not,

replace the drive gas assembly.

Display 2

The drive gas assembly is

nonlinear.

1. Replace the drive gas assembly.

2. Replace the VCM.

Display 3

nonlinear.

1.

Check whether the pipeline is connected

according to the instructions.

Loading...

Loading...