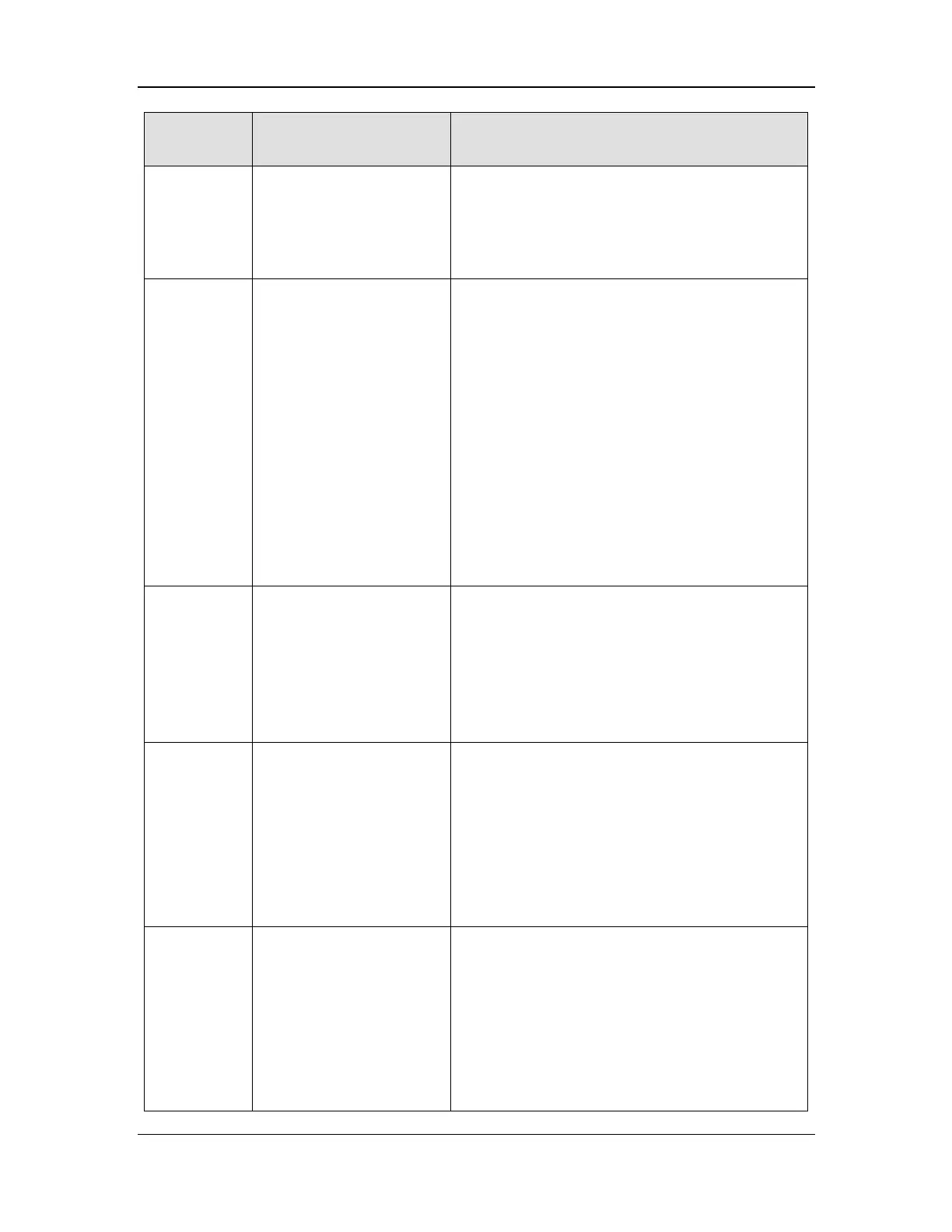

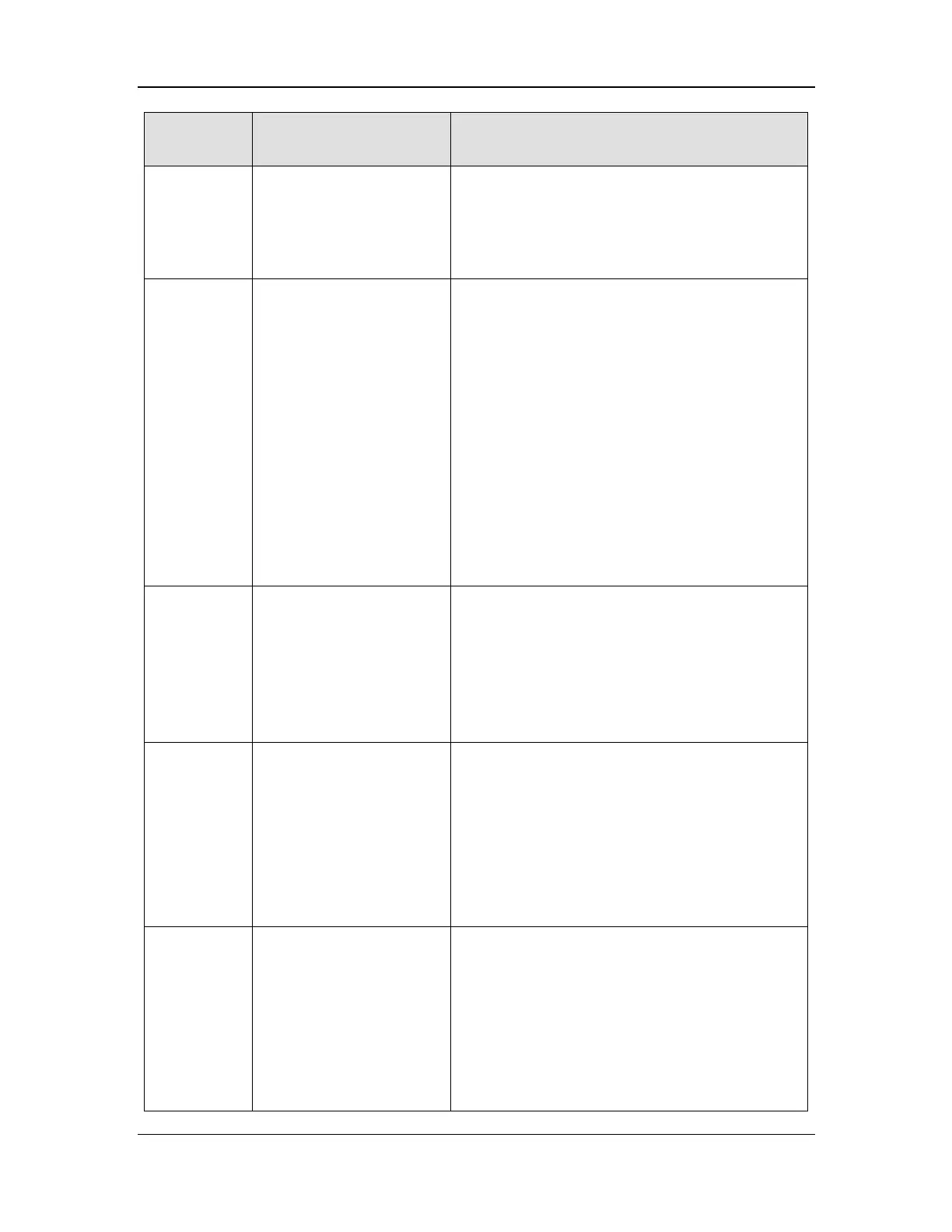

6-9

Failure

Description

Possible Cause Recommended Action

2. Check whether the gas supply is sufficient for

the whole calibration process. (T

gas pressure is not less than 345 kPa (50 psi).)

3. Check whether the calibration dev

properly.

Display 4

A zero point error occurs in

the expiratory flow sensor.

1. Check whether the fresh gas is turned off.

2.

Check whether the inspiratory valve can be

closed tightly. According to the valve

diagnosis tool, after the valve is closed, if the

gas supply is disconnected and then

connected, the AD values of the ventilator

flow sensor basically remain unchanged (the

reading change does not exceed 1%),

indicating that the valve is closed tightly. If

the valve cannot be closed tightly, replace the

drive gas assembly.

3. Check whether the zero point of the sensor is

red. If yes, calibrate the sensor again.

4. Replace the VCM.

Display 5

The expiratory flow sensor

is nonlinear.

1. Check whether the check valve is connected

correctly.

2. Check whether the sampling line is connected

correctly.

3. Replace the expiratory flow sensor.

4. Replace the VCM.

Display 6

The resolution of the

expiratory flow sensor is

incorrect.

1. Check the connection of the sampling line and

the gas tightness.

2. Check whether the gas supply pressure ranges

from 280 kPa (40 psi) to 600 kPa (87 psi).

3. Check the settings of the calibration device.

4. Replace the relevant flow sensor in the circuit.

5. Replace the VCM.

Display 7

The measurement range of

the expiratory flow sensor

is abnormal.

1. Check whether the sampling line is connected

correctly.

2. Start the valve diagnosis tool in the calibrated

pneumatic connection environment, set PEEP

Valve Current

expiratory valve based on 500 mA, gradually

increase the current of the inspiratory valve

(Insp Valve Current

), and observe the

measured value of the calibration device under

Loading...

Loading...