Maintenance 7-3

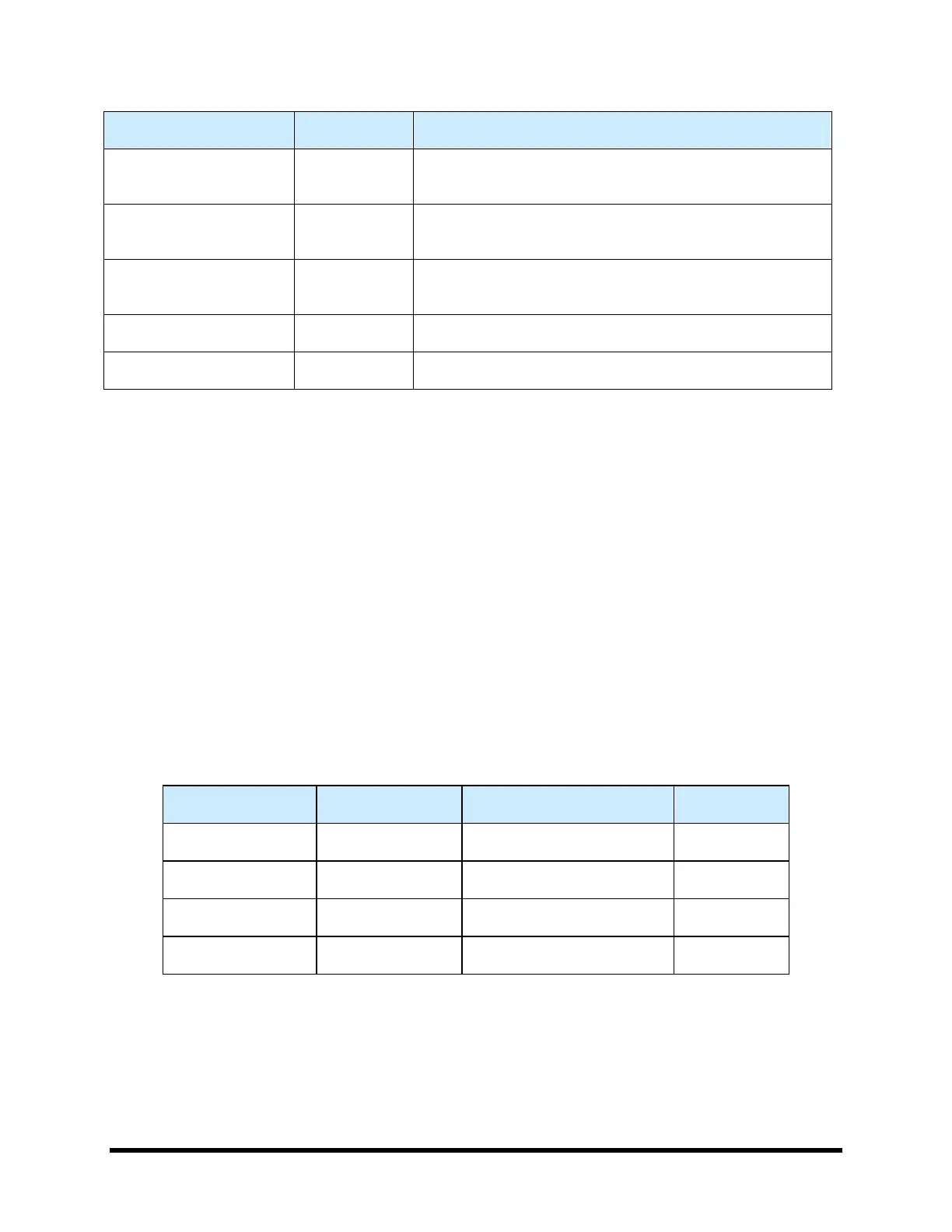

Table 7-1 Routine Maintenance Procedures (Continued)

Task Frequency Instructions

Lubricate Mechanical

Drive Cables

Every three

months

See 7.8.1 Lubricating the Cables.

Clean Camera Lens

Every three

months

Use the cleaning kit provided.

Tension Mechanical

Drive Cables

Every 6-12

months

See 7.9 Tensioning the Cables.

Tension Conveyor Belts As Needed See 7.10 Tensioning the Conveyor Belts.

Replace Conveyor Belts As Needed See 9.7 Replacing the Conveyor Belts.

7.5 Replacing Consumables

Consumables are items that are discarded and replaced on a regular basis. The following items are

common consumables and should be replaced at the intervals recommended in Table 7-1.

• Purge Boots

• Scale and Purge Cups

Tools and Materials Needed

• Needle-nosed Pliers • Replacement Purge Boot (see Table 7-2)

• Isopropyl Alcohol • Replacement 1 oz. (29 ml) Plastic Cups (P/N 58-0030)

• Clean Shop Cloth • Small Brush

• Rubber Gloves • Personal Protective Equipment (as required)

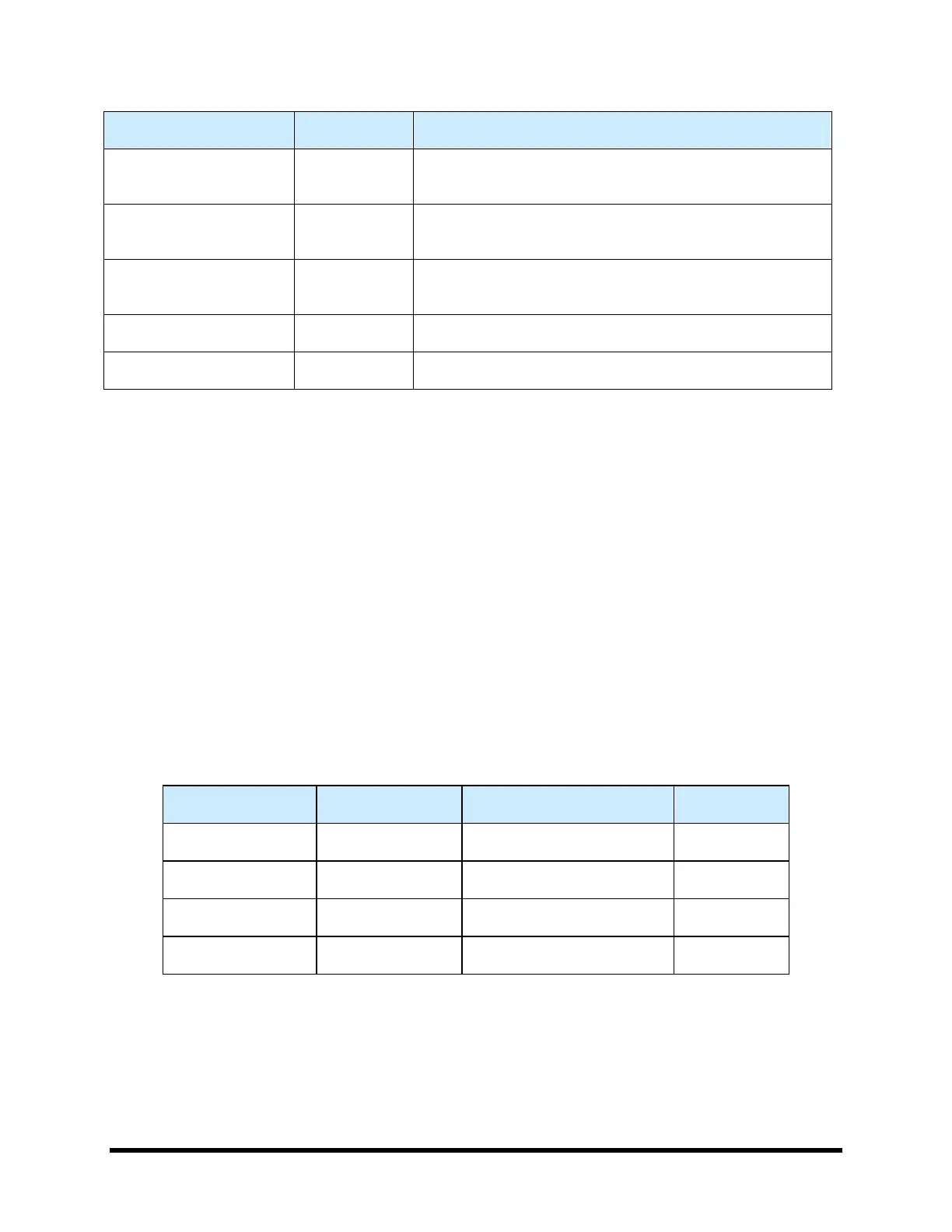

Table 7-2 Purge Boot Colors, Sizes, and Compatible Needles

Purge Boot Color Inside Diameter Compatible Needle Gages Asymtek P/N

Orange 0.5 mm (0.020-in.) 26, 27, 30, 32 01-0019-00

Pink 0.8 mm (0.031-in.) 22, 23, 24, 25 01-0021-00

Green 1.1 mm (0.045-in.) 19, 20, 21 01-0018-00

Olive* 3.0 mm (0.120-in.) 14, 15, 16, 18 01-0022-00

*Recommended size for nozzles on DJ-2000 and DJ-9000 Series Dispensing Valves.

Loading...

Loading...