10-2 Specifications

10.3 Specifications

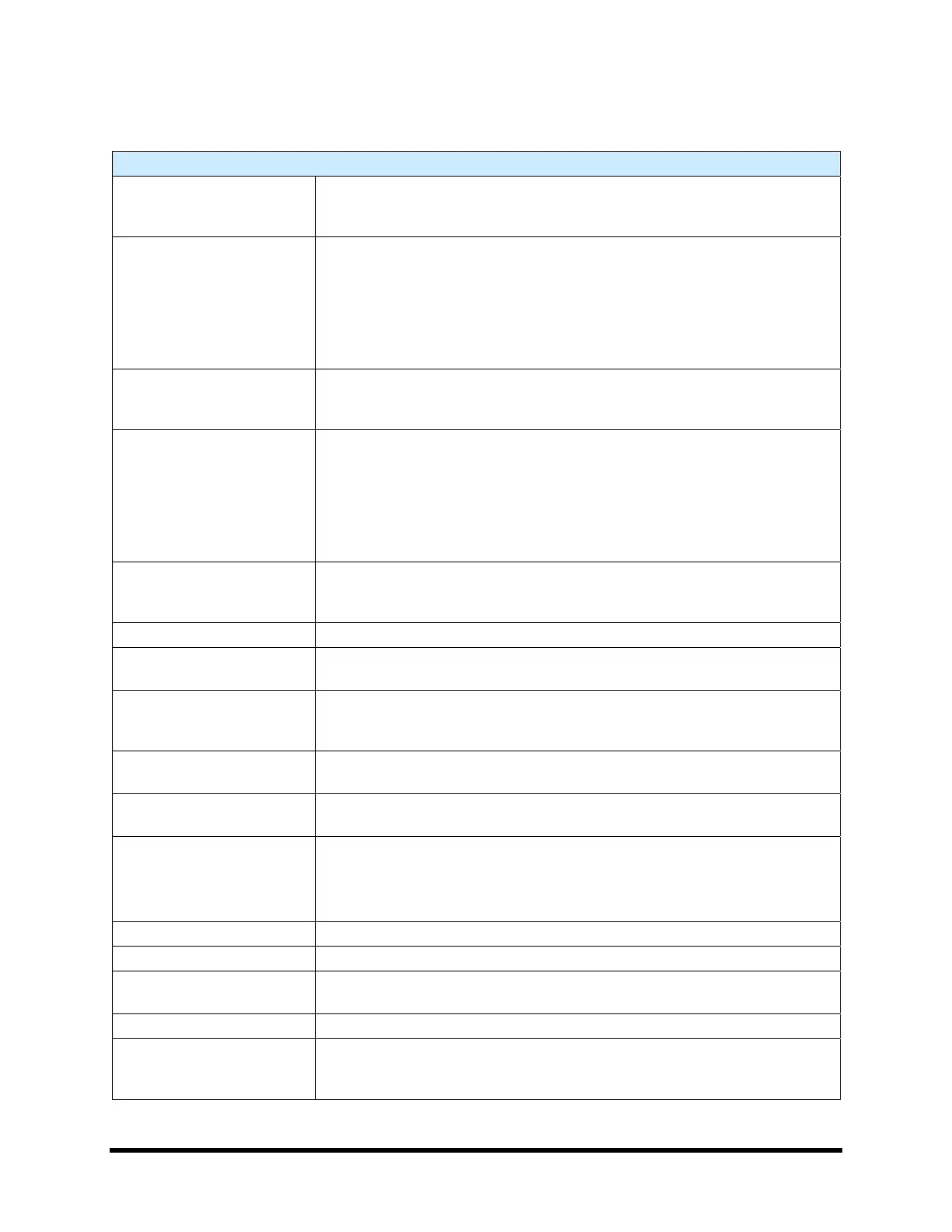

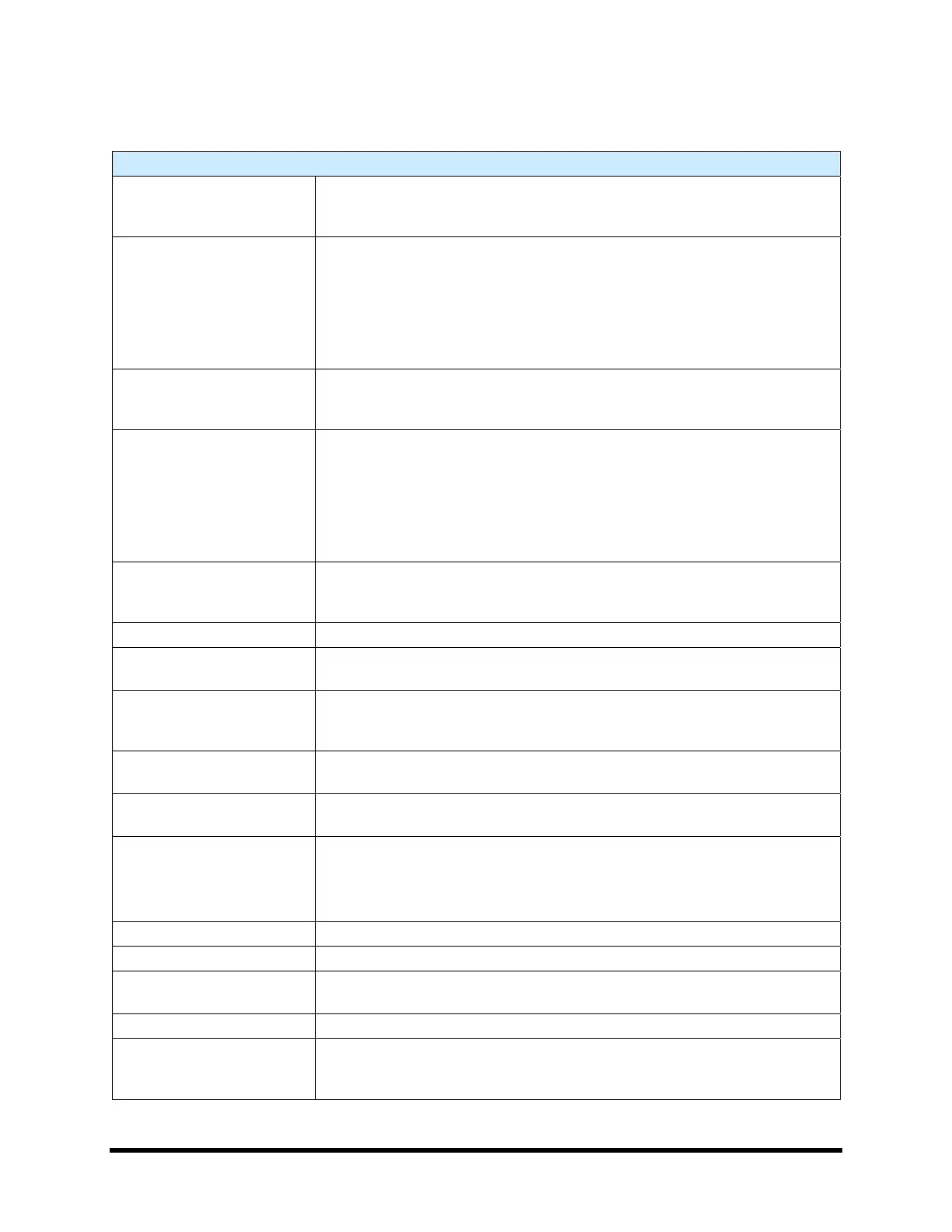

Table 10-3 Specifications

Specifications

Dispensing Area

Single Dispense Head: 340 mm x 415 mm [13.4 in. x 16.3 in.]

Z-Travel: 60 mm

Z-Axis Payload: 3 kg

Motion System

Type: Brushless DC servo motors, closed-loop encoder feedback

X-Y Velocity: 1000 mm/s maximum

Z-Axis Velocity: 500 mm/s maximum

X-Y Repeatability: ±0.025 mm (0.001 in.)

Z-Axis Repeatability: ±0.025 mm (0.001 in.)

X-Y-Z Resolution: 0.005 mm (0.0002 in.)

Positional Accuracy: ±0.050 mm (0.002 in.)

Vision and Lighting

Vision system with Automatic Pattern Recognition

Image size: 6.35 mm (0.25 in.) standard

Lighting: Programmable, red/blue LED, 256 steps

Conveyor

SMEMA Compliant

Single or Dual Lane Configuration

Flat Belt

Motorized Rail Spacing

1 Dispensing Station standard, 3 Dispensing Stations available

Fiber-optic over-the-rail board sensors at all stations

Over-the-rail stop pins

Service Station

Needle Vacuum Purge Cup

On-Board High Precision Scale

Needle Calibration Substrate

Heaters 120°C, ± 5°C for impingement heaters

Height Sensor

Standard: Integral Mechanical Height Sensor

Optional: Laser

Computer

Windows-based Laptop PC with DVD-RW drive

User interface: Color LCD flat-panel display; ASCII keyboard & touchpad;

Ethernet network port, left and right USB ports

Software

User Environment: Fluidmove for Windows XP

Operating System: Windows XP

Fluid Delivery Method

DispenseJet DJ-9000; DJ-2200, Heli-flow DV-7000 and DV-8000 pumps;

DV-01, DV-02, DV-03, DV-05, DV-07, DV-09.

Energy Consumption

S-920 Idle: 550 W

S-920 Peak: 1000 W (Not including heaters)

S-922 Idle: 625 W

S-922 Peak: 1075 W (Not including heaters)

AIC Interrupt Capacity 10kA

Audible Noise Level 70 dBA, 76 db peak

Ionizing and Non-ionizing

Radiation

N/A

Contaminants N/A

Residual Risks of

Materials Used to

Construct Equipment

None

Loading...

Loading...