- Repeat for the reference between driving pulley

and transmission housing.

- Refit the inspection cap on the flywheel side.

- Connect the diagnostic tester.

- Start the engine.

- Select the «parameters» function in this menu.

- Select the stroboscopic light control in the tradi-

tional four-stroke engine position (1 spark, 2 revs).

- Check that the real values of rpm and ignition

advance match those measured using the diag-

nostic tester.

Specific tooling

020680Y Diagnosis Tool

If the values do not match, check:

- distribution timing

- revolution timing sensor

- injection control unit

This section described the operations to be carried out on the manifold components.

Inspecting the radial air gap

- Align a tooth of the tone wheel with the revolution timing sensor.

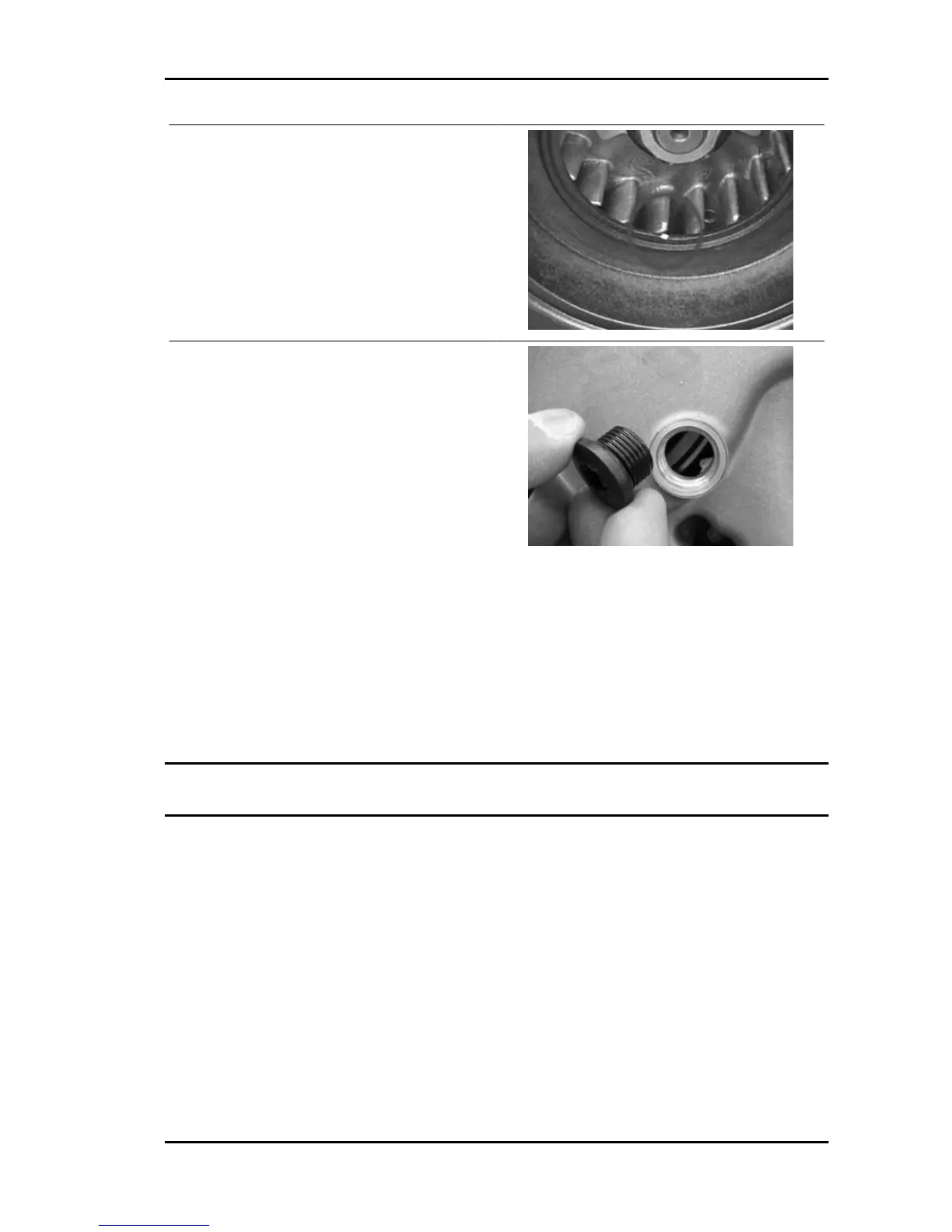

- Check the air gap using a probe.

Characteristic

Standard air gap:

from 0.20 to 0.70 mm

Beverly 500 i.e. Engine

ENG - 133

Loading...

Loading...