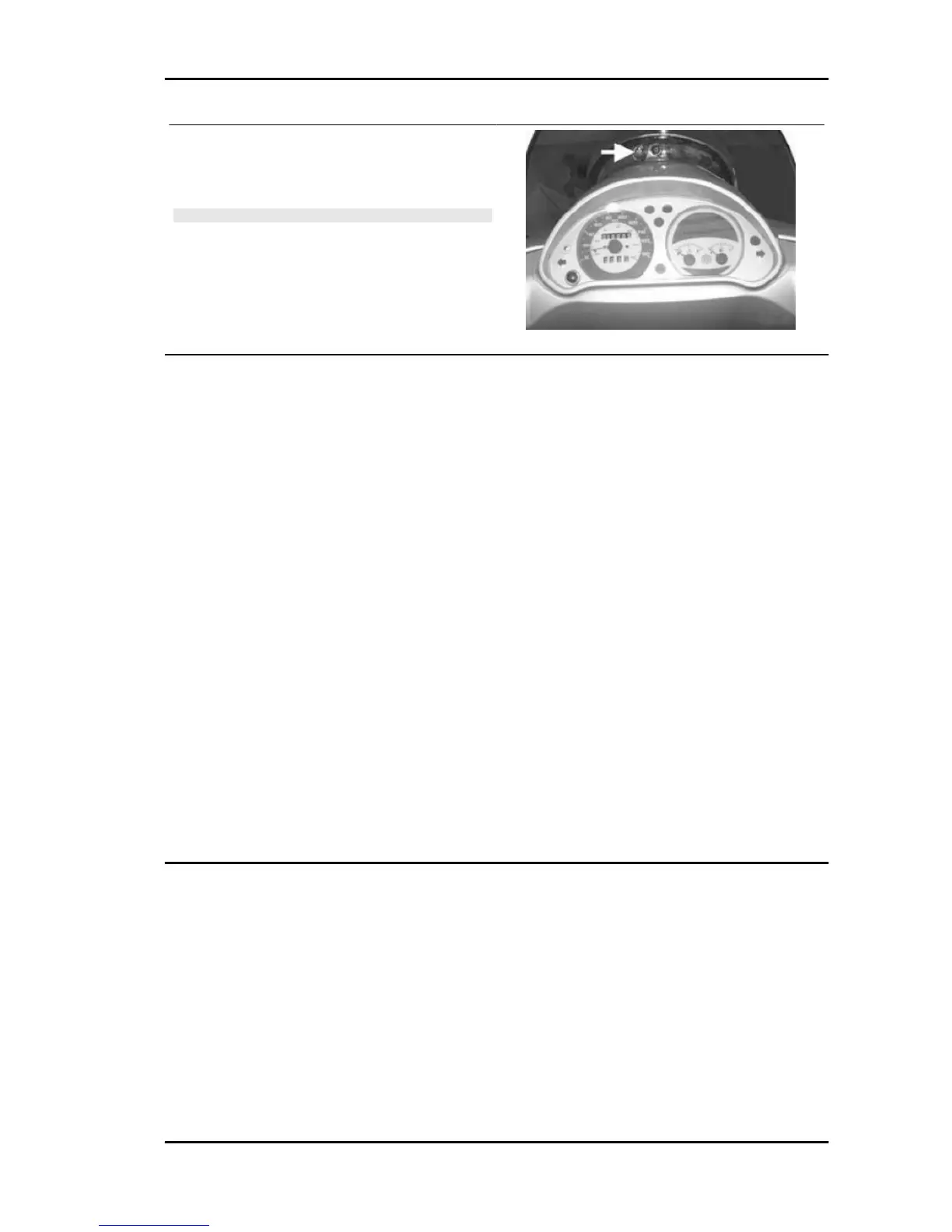

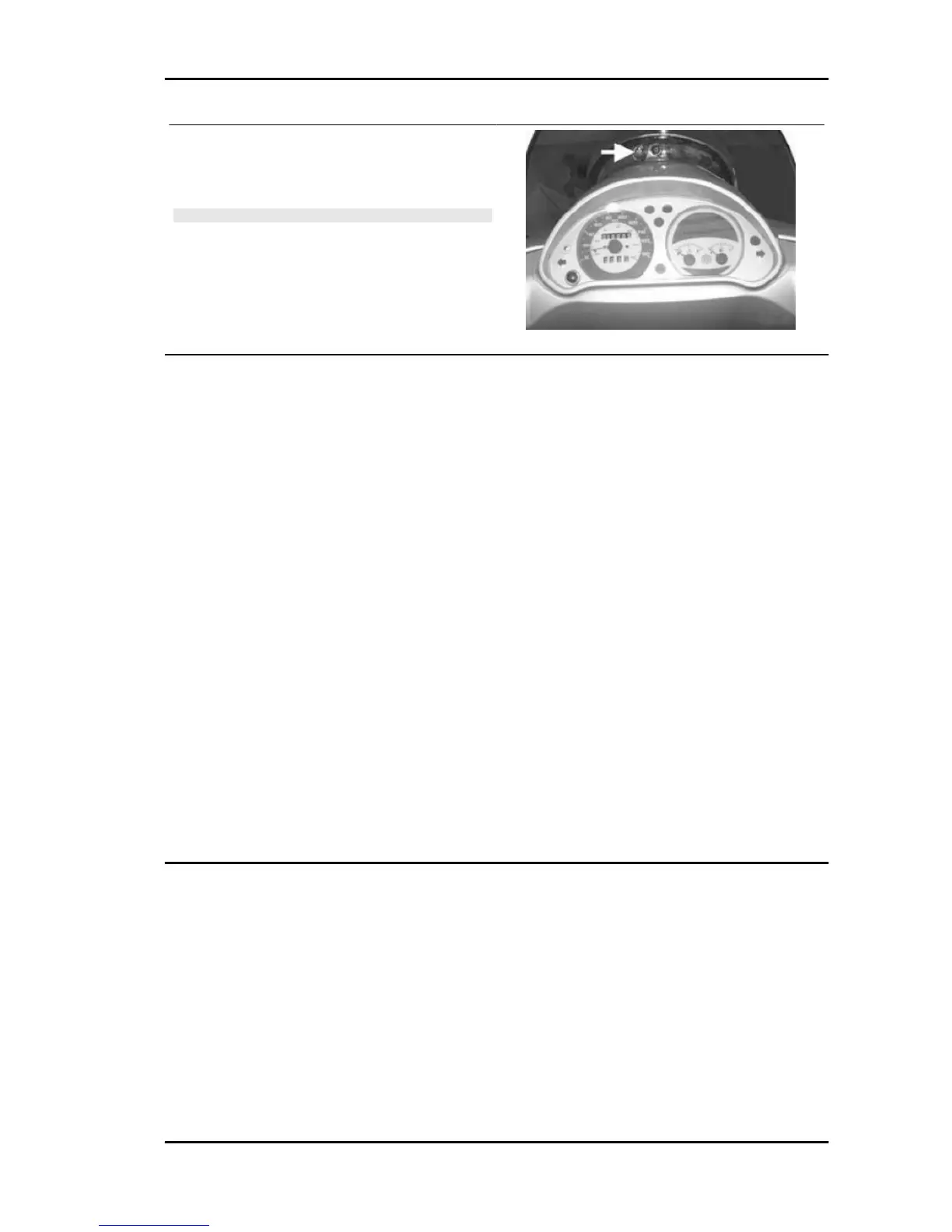

- Otherwise, adjust the right headlight by the screw

shown in the figure, which can be accessed by re-

moving the front shield connecting member.

N.B.

THE ABOVE PROCEDURE COMPLIES WITH THE EURO-

PEAN STANDARDS REGARDING MAXIMUM AND MINI-

MUM HEIGHT OF LIGHT BEAMS. REFER TO THE STATU-

TORY REGULATIONS IN FORCE IN EVERY COUNTRY

WHERE THE VEHICLE IS USED.

Checking the end compression pressure

•

Remove the spark plug cap when the engine is cold.

•

Remove the ignition spark plug.

•

Fit a compression test gauge into the spark plug seat using a 10 mm spark plug union at

the proper tightening torque.

•

Disconnect the revolution-timing sensor connector.

•

Let the engine run using the starter and with the throttle body in fully open position as long

as the gauge value is steady. If pressure is correct (> 11 bar), remove the tool and reinstall

the spark plug, the cap and the rev counter connector.

•

If the pressure is less than indicated, check the rpm at which the test is carried out; if it is

less than 450 rpm, check the starter system; if not, check the following:

•

Distribution timing

•

Valve clearance

•

Check valve seal

•

Check lining seal

•

Proper compression ratio selection

Locking torques (N*m)

Fitting for compression test 10

Beverly 500 i.e. Maintenance

MAIN - 31

Loading...

Loading...