3 - Perform the injector sealing test.

Dry the injector outlet with a blast of compressed

air. Activate the fuel pump. Wait for one minute,

making sure there are no leaks coming from the

injector. Slight oozing is normal.

Value limit = 1 drop per minute

YES go to 5 NO go to 6

4 - Higher quantities are not expected.

For lower quantities, replace the injector (THER-

MAL GROUP AND TIMING SYSTEM).

5 - The injector is conforming.

6 - Repeat the test. If the fault continues, replace

the injector (THERMAL GROUP AND TIMING

SYSTEM)

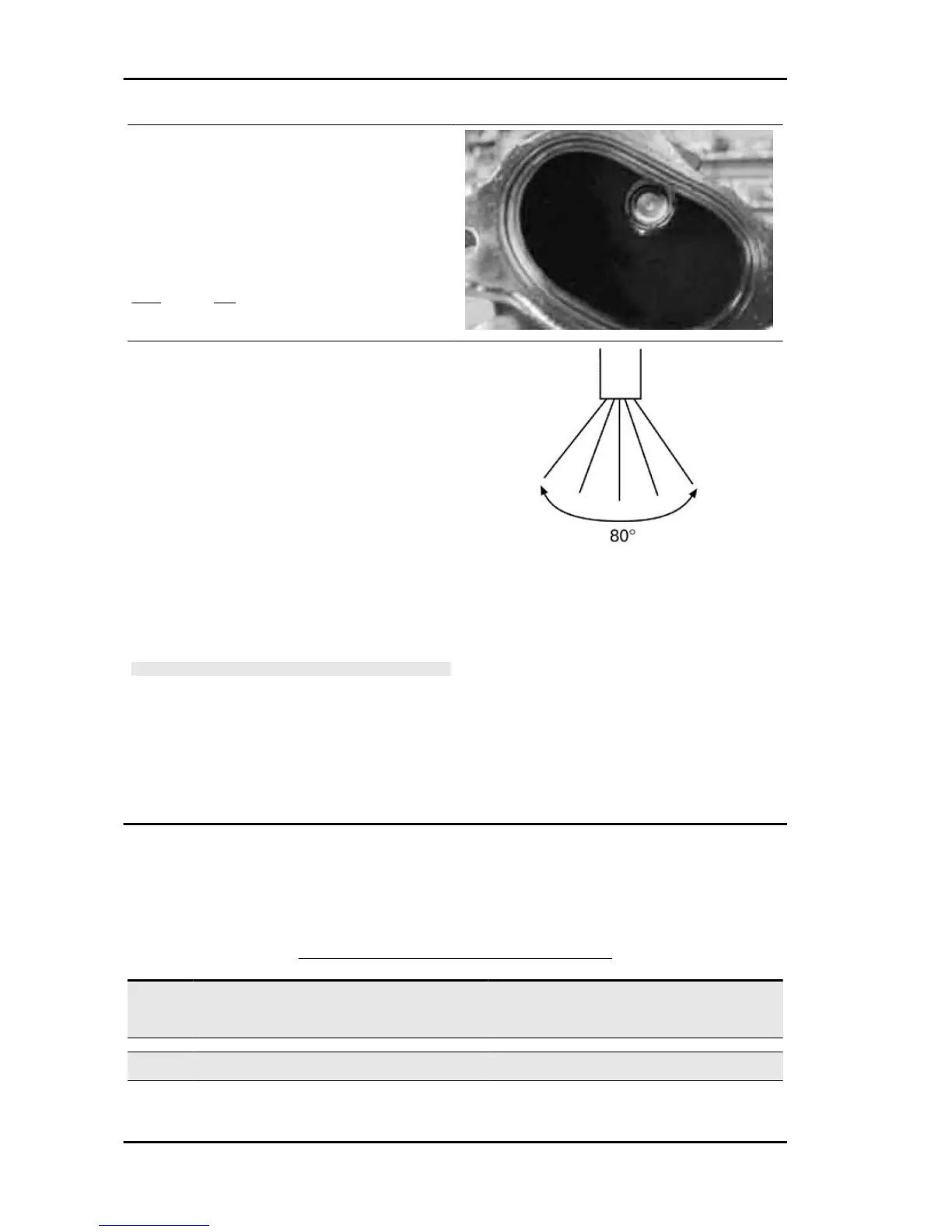

The injector atomisation cannot be checked by

simple methods. The injector is provided with 5

holes whose angulation forms a jet with a taper of

about 80°. The jet thus formed impinges both in-

take valves.

N.B.

- AN INJECTOR WITH LOW FLOW RATE AFFECTS THE

MAXIMUM PERFORMANCE.

- AN INJECTOR WITH POOR SEAL AFFECTS IDLING AND

THE START-UP FEATURES AFTER A SHORT STOP WITH

HOT ENGINE.

- IN CASE OF CLOGGING OF THE INJECTOR, IT IS NEC-

ESSARY TO REPLACE IT, ALONG WITH THE FUEL FILTER

CONTAINED IN THE TANK. CAREFULLY CLEAN THE SYS-

TEM AND THE TANK.

Troubleshooting

1 - A failure of the EMS system is more likely to be due to the connections than to the components.

Before searching the EMS system for failures, perform the following checks:

SUGGESTION FOR TROUBLESHOOTING

Specification

Desc./Quantity

1 1. Power supply - Battery voltage

- Burnt fuse

- Remote control switches

- Connectors

2 2. Chassis earth

3 3. Fuel supply - Faulty fuel pump

- Dirty fuel filter

4 4. Ignition system - Faulty spark plug

- Faulty coil

- Faulty screened cap

Injection Beverly 500 i.e.

INJEC - 214

Loading...

Loading...