- Relay closure

- Pump rotation

- Relay opening

YES go to 31 NO go to 32

31 - The pump is fed. Perform a functional check of the pump.

32 - Check the efficiency of the pump connector.

YES go to 33 NO go to 34

33 - Replace the fuel pump.

34 - Restore

The injection CPU manages the negative of the light. The light must go off after the initial check. The

light goes on again when the CPU autodiagnosis detects a fault. When the fault disappears the light

goes back off, however, the related operating tests need to be carried out. The light can go on whether

the engine is able to run or not.

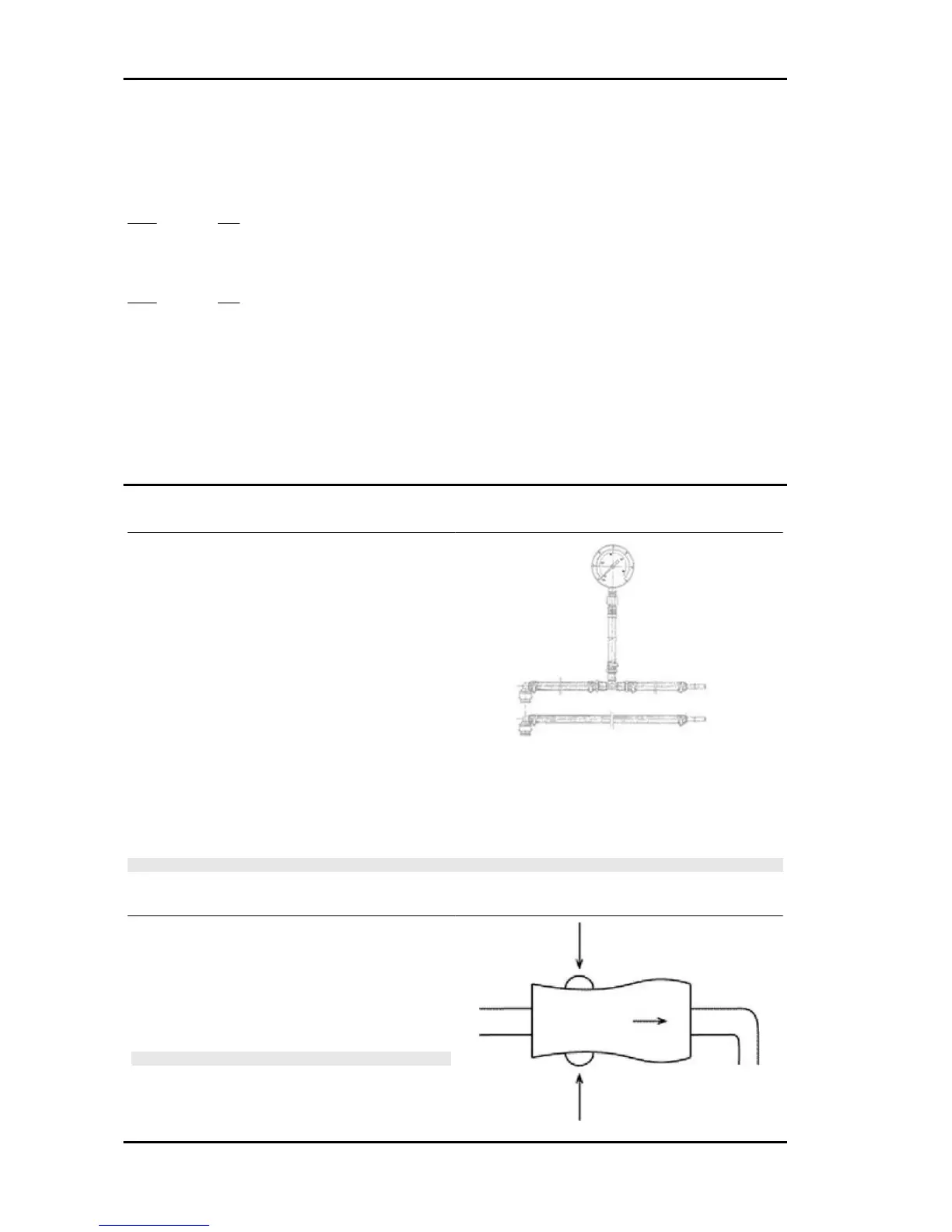

Circuit leak test

Before performing the checks concerning the sys-

tem pressure, it is necessary to carefully clean all

feeding system components.

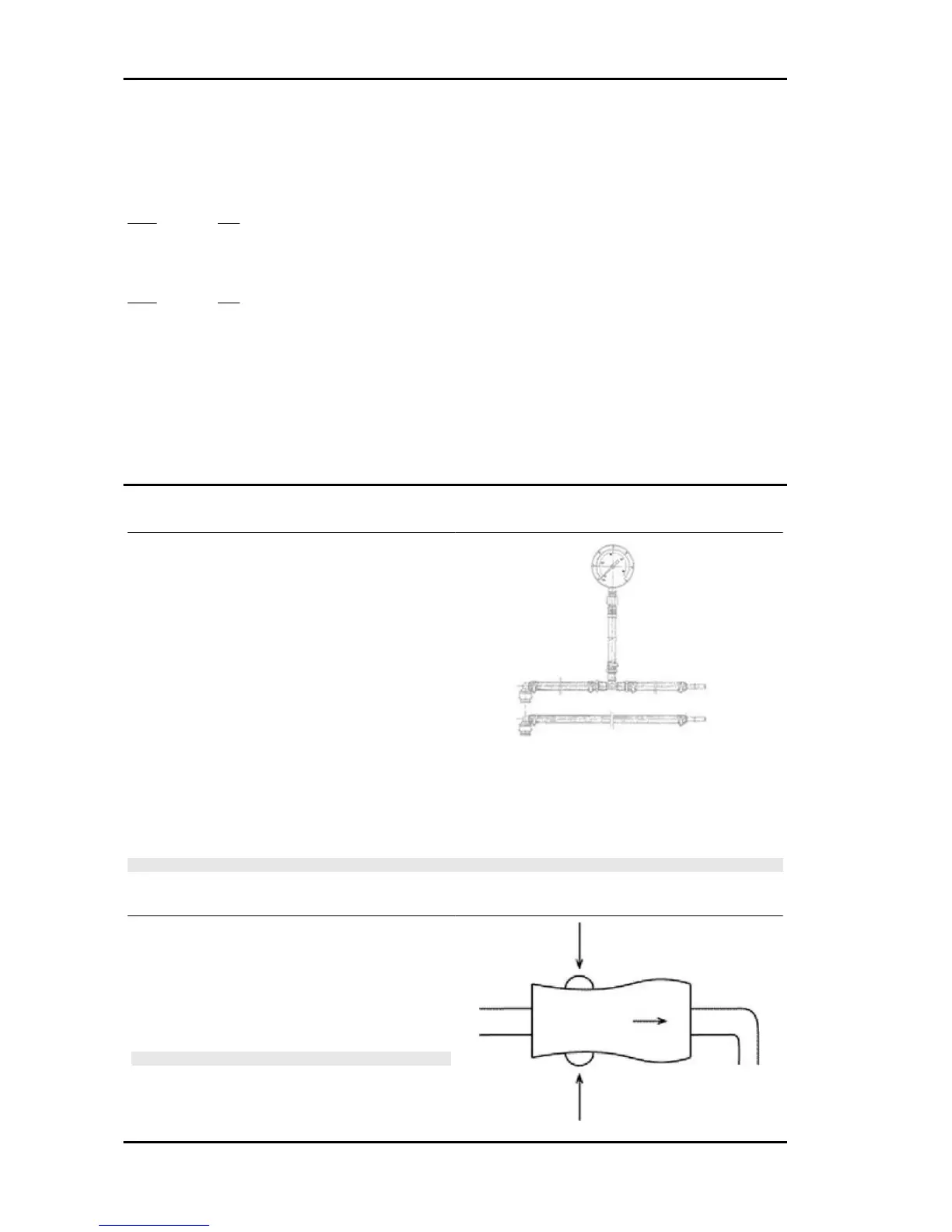

To perform the inspections it is necessary to use

the special tooling kit for fuel pressure check.

Specific tooling

020480Y Petrol pressure check kit

Before disconnecting any fastener, reduce the system pressure.

Detach the electrical connector from the pump support with the engine running, and wait for the shut-

down.

The engine stops at approximately 1.5 bar.

CAUTION

CAREFULLY DETACH THE HOSE TERMINAL PREVENT ANY POSSIBLE SPRAYING INTO THE

EYES.

The special tool is equipped with fast-release fit-

tings, similar to those provided for the circuit.

In order to disconnect the female terminals (injec-

tor side), it is necessary to press the two exten-

sions and draw them.

CAUTION

DO NOT FORCE THE TERMINAL IF THIS DOES NOT COME

LOOSE; EVENTUALLY, TRY TWISTING IT. THE TERMINAL

IS DESIGNED SO THAT AN INCREASE IN TENSION IN-

CREASES THE LOCKING FORCE.

Injection Beverly 500 i.e.

INJEC - 198

Loading...

Loading...