020680Y Diagnosis Tool

2 - The EMS system has received no indications of temperatures out of the range of possible temper-

atures.

If you suspect a wrong temperature indication, proceed to perform the following check.

N.B.

A WRONG TEMPERATURE SIGNAL CAN BE DETECTED BY COUPLING THE ANALOGUE IN-

STRUMENT INDICATION WITH THE ELECTRIC FAN START.

IN ANY CASE, BEFORE CHECKING THE SENSOR, CHECK THE FILLING AND BLEEDING OF

THE COOLING SYSTEM

3 - Before checking the sensor and the relevant circuit, wait until the engine has cooled down and the

scooter has set to the working area temperature.

YES go to 4

4 - Set the switch to "ON" with switch to "RUN" and side stand raised. Select the menu on the "param-

eters" function. Do not start the engine.

YES go to 5

5 - Check the following values: coolant temperature intake air temperature ambient temperature The

three indications are equal or they are slightly different (e.g. 1° C).

YES go to 6 NO go to 7

6 - The temperature sensor is providing probably correct information.

Check at approx. 80° C.

7 - Install the special tool.

WARNING

DO NOT CONNECT THE CONTROL UNIT CONNECTOR.

Specific tooling

020481Y Control unit interface wiring

YES go to 8

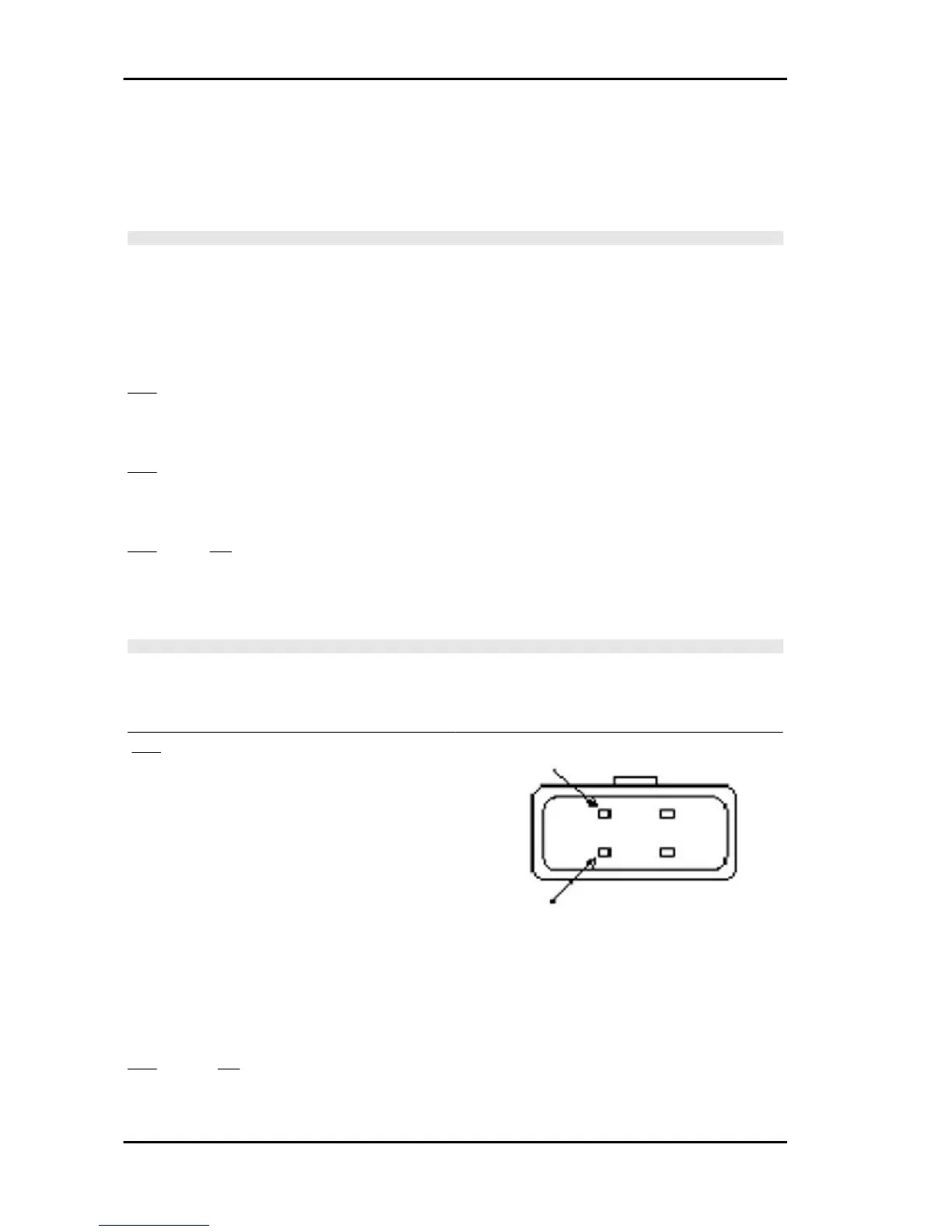

8 - Disconnect the coolant temperature sensor

connector. Measure the sensor resistance be-

tween the terminals shown in the figure.

Check that the resistance matches the values de-

clared according to the temperature.

Electric characteristic

TEMPERATURE RESISTANCE

9.6KW -10° C

5.975KW. 0

3.81KW +10° C .

2.5KW +20° C

1.68KW +30° C

0.3KW +80° C

YES go to 10 NO go to 9

9 - Replace the sensor.

10 - Connect the sensor connector and repeat the resistive check at terminals 4 and 22;

Injection Beverly 500 i.e.

INJEC - 238

Loading...

Loading...