7088-8000

-39

Low Flow Cutoff (Menu 34)

When a zero flow condition occurs (for example, as

the result of a pump being shut off), internal sloshing,

check valve leakage, and other fluid movement can

prevent the flowmeter from reading total zero. This

phenomenon can result in totalizer errors.

These errors can be minimized by entering a low flow

cutoff (a minimum acceptable value for flow) in this

menu. Setting a low flow cutoff drives the flowmeter

to zero for flow rates at or below that value. If the flow

rate (regardless of direction) falls below the low flow

cutoff value, the instrument’s indicated flow is driven

to zero and the totalizers stop incrementing.

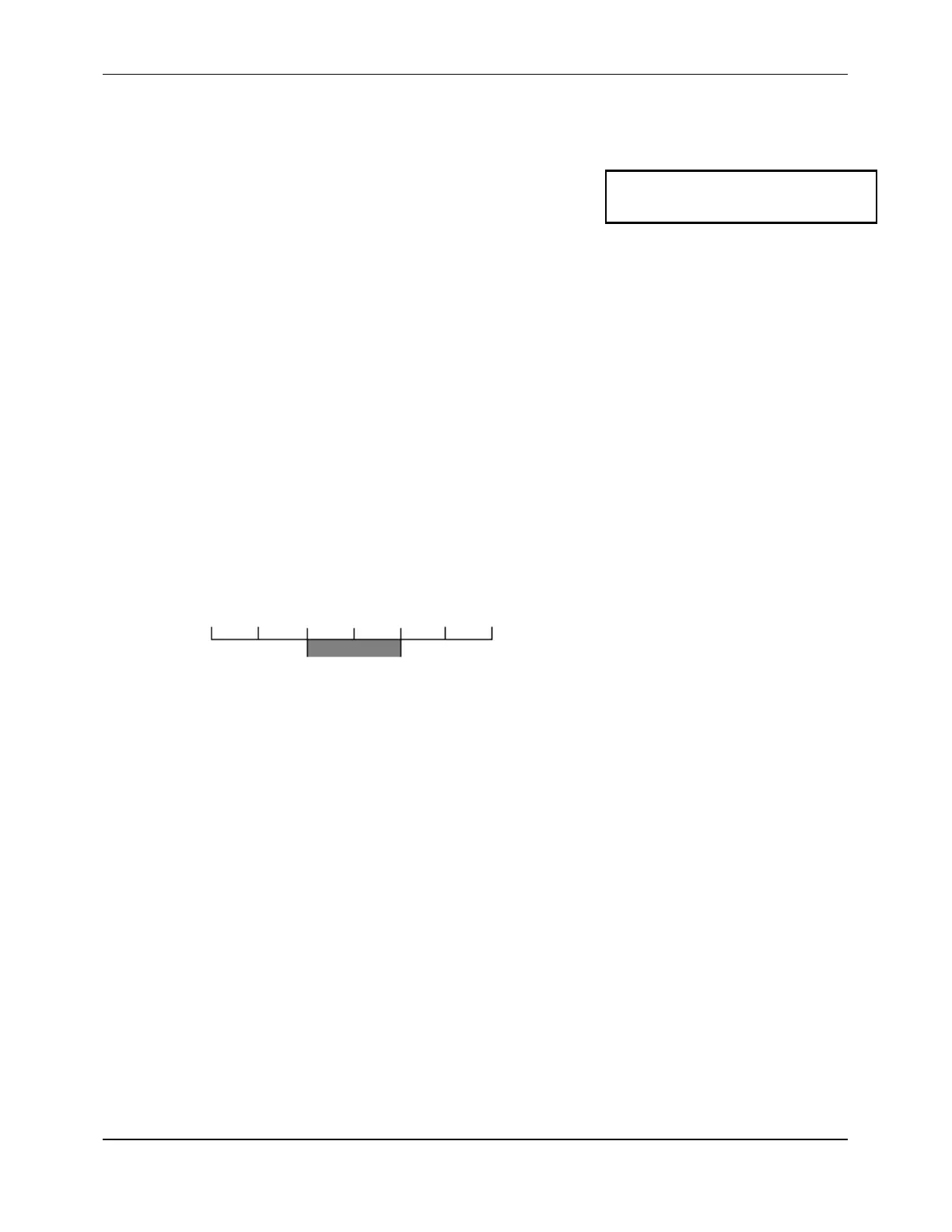

For example, if a low flow cutoff of 0.1 foot per

second (.03 meters per second) is entered, the

instrument would be driven to zero for flow rates less

than 0.1 foot per second in the positive direction and

greater than -0.1 foot in the negative direction

(Figure 3-2).

-0.3 -0.2 -0.1 0 +0.1 +0.2 +0.3

Zero flow

displayed here

Figure 3-2 Low Flow Cutoff (example)

NOTE:

The default setting for the low flow cutoff is

1.0.

Low Signal Cutoff (Menu 35)

Empty pipes or solids, bubbles, or voids in the flow

stream may cause temporary drops in signal strength

and erroneous readings. The effect of these dropouts

can be minimized by setting a low signal cutoff.

Setting a low signal cutoff (a minimum acceptable

signal amplitude), drives the flowmeter to the

loss-of-signal (LOS) condition.

Low Flow Cutoff

0.00 GPM

Loading...

Loading...