EGM-5 Operation Manual V. 1.04 75 support@ppsystems.com

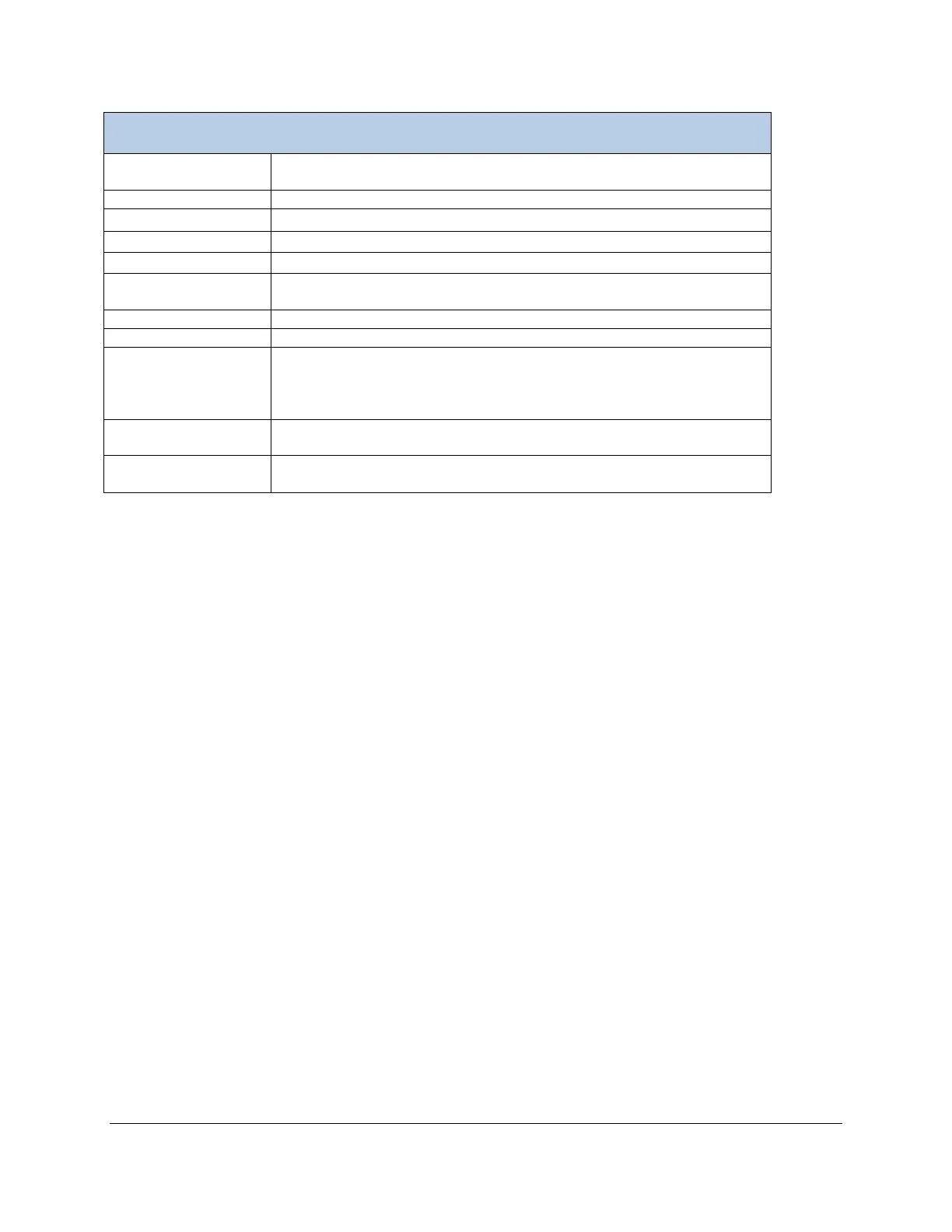

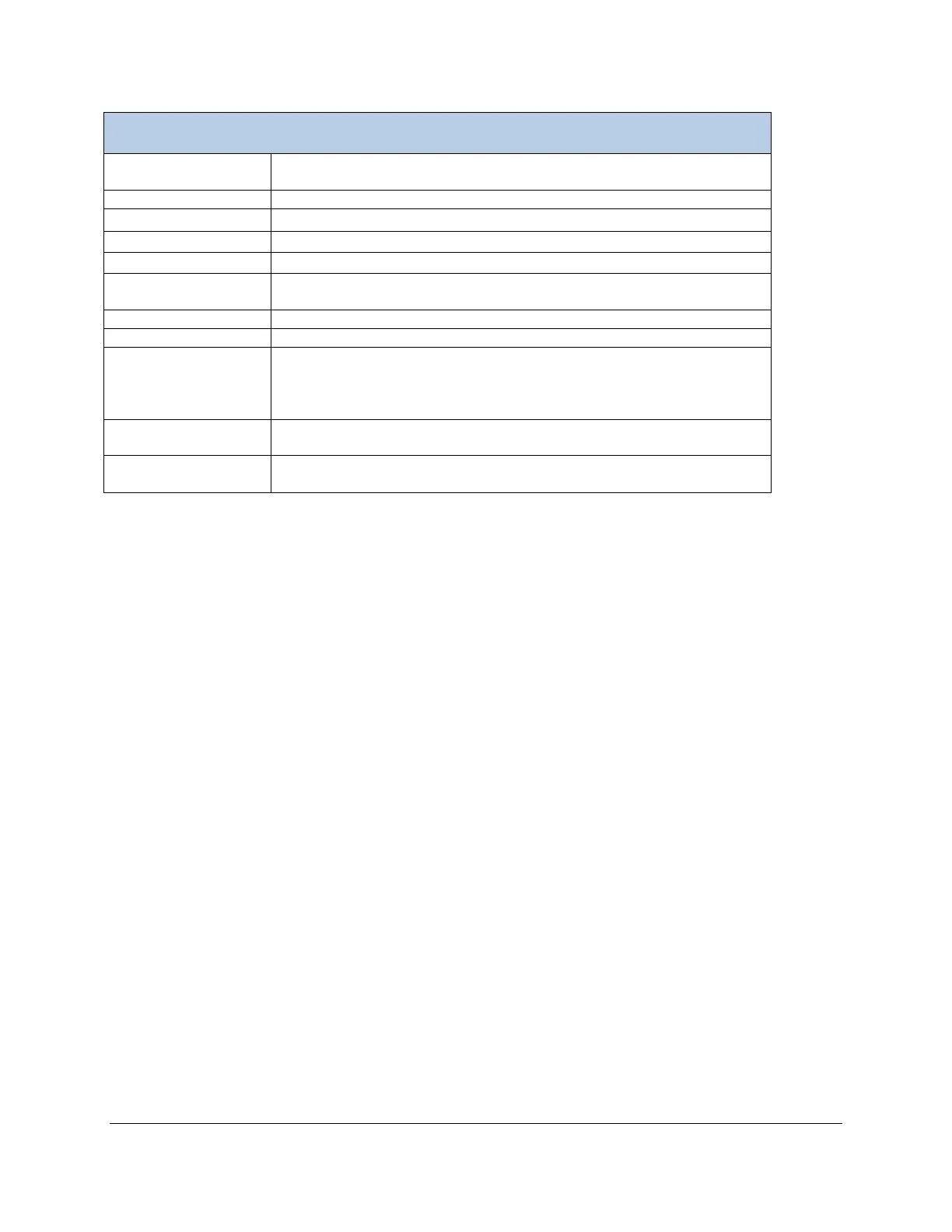

Pulses on and off to indicate that the system is powered on (power

status).

Percentage of battery life remaining.

2

concentration in tubing (ppm).

2

concentration inside syringe (ppm).

2

INJT Indicates that the process is in the injection phase. END

indicates CO

2

concentration calculations have been terminated.

Time (seconds). It is fixed at 180 seconds.

CO

2

concentration in tubing (ppm).

2

maximum. This is set to be ¼ of the Max CO

2

value for the Graph setting and can be modified under Main >

Settings > Settings 2 > Graph. (For example, when Max CO2 is set to

1000 ppm, this graph shows 250 ppm.)

Stops the Injection process and returns to the Injection Baseline menu

(Step 4). Process results are not saved to the USB flash drive.

Stops the Injection process and returns to Injection Baseline menu

(Step 4). Injection Process results are saved to the USB flash drive.

Typically during an injection, the first value will rise quickly and drop back to zero; correspondingly, the

value of M will increase quickly as the value of C peaks and then plateaus at a constant value. Once C

has dropped to 0 ppm (or a very low background value), wait 3-5 seconds to make sure M has stabilized

and take note of the value. This value is also recorded on the USB memory stick, if a memory stick has

been inserted.

Errors from injection measurements are typically larger than flow-through methods (larger errors could

come from both instrumental and handling sources), so it is recommended that you measure the same

sample multiple times and calculate an average whenever possible.

Static Process

If static sampling is selected, the user can inject samples directly into the sample cell through the port

labelled GAS OUT rather than having the sample pumped through it. This is normally done using a

syringe with 1/8” tubing on the end which can easily fit over the GAS OUT port on the EGM-5. For static

measurements injected directly into the “Gas Out” port, we recommend a minimum sample volume of 5

ml.

Note: The system will still perform its regularly scheduled zeros even if a Static measurement is ongoing.

A warning will be displayed 2 minutes before the zero and again 1 minute prior. The onboard pump will

turn on during the zero. Upon completion of the zero the pump will again switch off.

The general procedure for taking a Static measurement is as follows:

1. Navigate to Main > Processes > Static.

2. Press the right arrow button to begin the Static Process.

3. A zero is automatically performed.

4. After the zero is completed (the sample pump is now off), the system is ready for a sample

injection.

Loading...

Loading...