Rockwell Automation Publication 2198-UM001M-EN-P - November 2022 85

Chapter 5 Connect the Kinetix 5500 Drive System

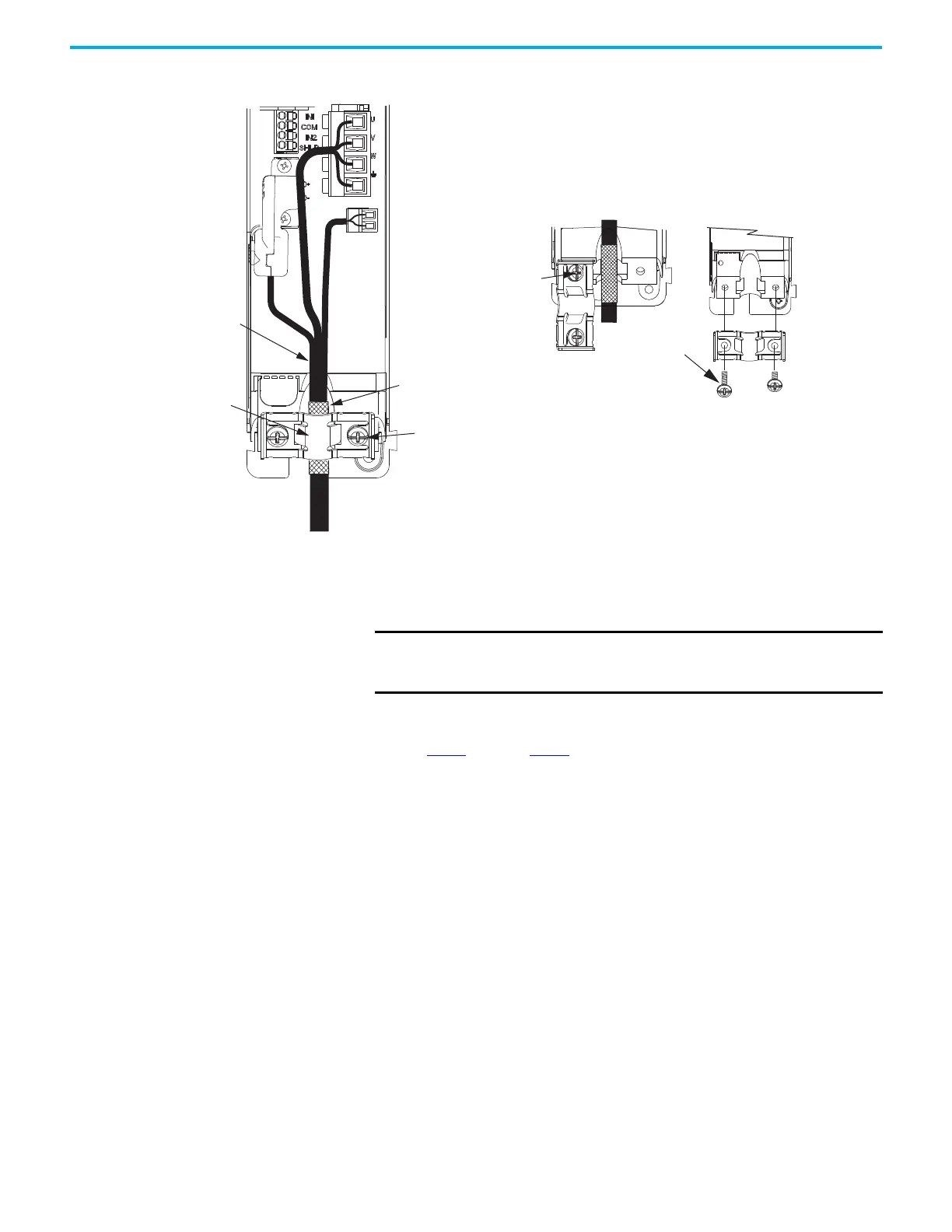

When the drive/motor combination calls for 14 AWG or 10 AWG cable,

the feedback cable routes along with the power and brake wiring.

2. Position the exposed portion of the cable shield directly in line with the

clamp.

3. Tighten each screw a few turns at a time until the maximum torque value

of 2.0 N•m (17.7 lb•in) is achieved.

4. Repeat step 1

through step 3 for each drive in multi-axis configurations.

Motor Cable

Shield Clamp

Motor Power

(MP) Connector

Motor Brake

(BC) Connector

Exposed shield braid

under clamp.

Shield Clamp Screws (2)

Feedback cable routed

within the shield braid.

Kinetix 5500 Servo Drives,

Frame 2 or 3, Front View

(frame 2 is shown)

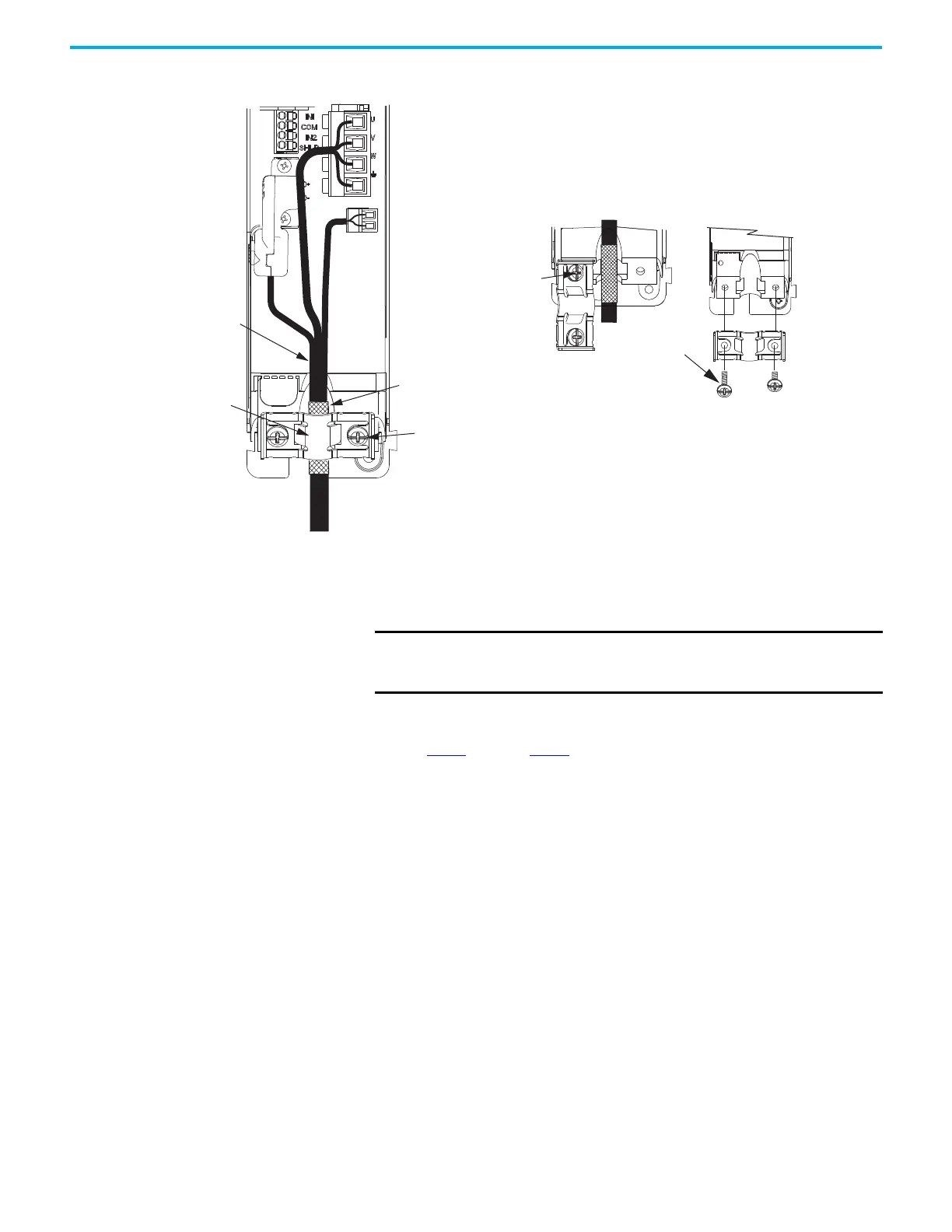

2198-KITCON-DSL

Motor Feedback

Connector Kit

Retention Screw

(loosen, do not remove)

Clamp features apply to all

frame sizes.

Torque clamp screws to

2.0 N•m (17.7 lb•in), max

2090-CSxM1Dx-14xxxx

Single Motor Cable

Servo Drive

Shield Clamp

Clamp Screws

2.0 N•m (17.7 lb•in)

Retention

Screw

14 AWG and 10 AWG Cable Installation Example

IMPORTANT Loosen the retention screw, if needed, until you can start

threading both clamp screws with the cable shield under the

clamp.

Loading...

Loading...