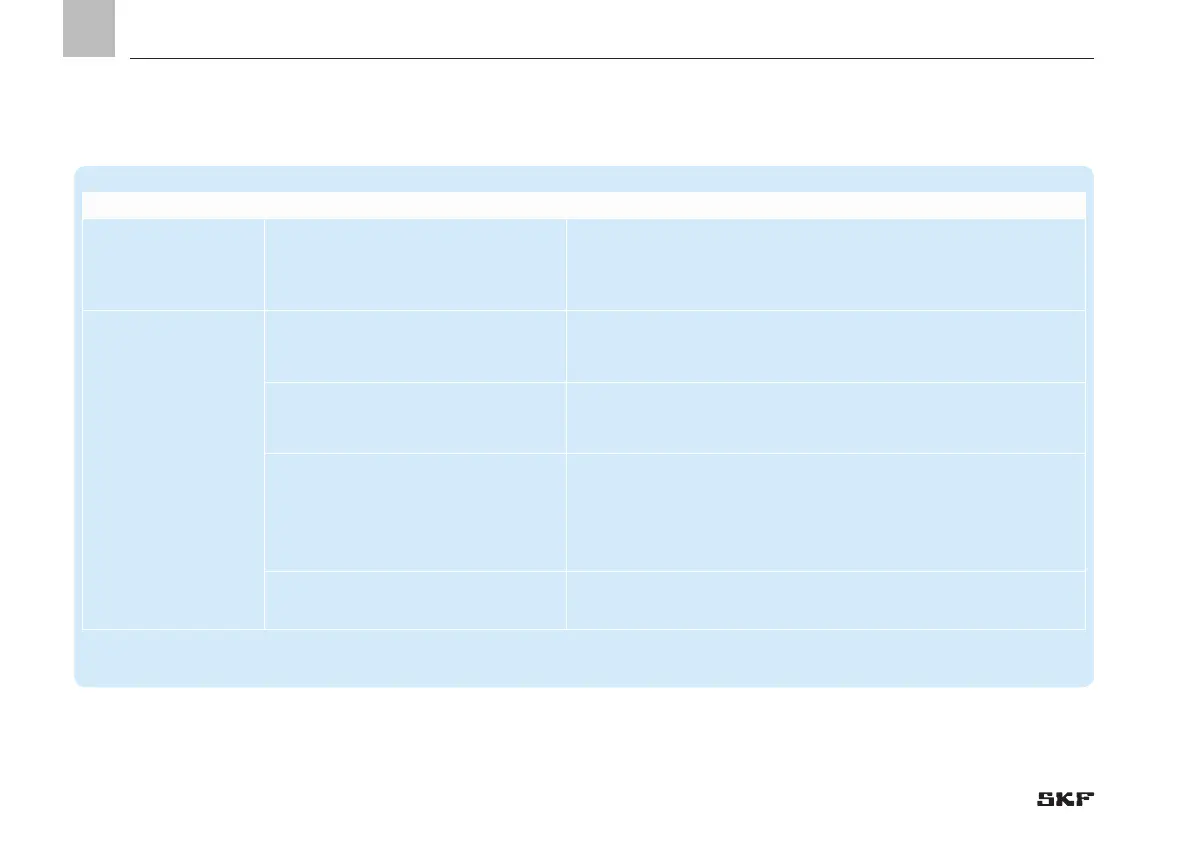

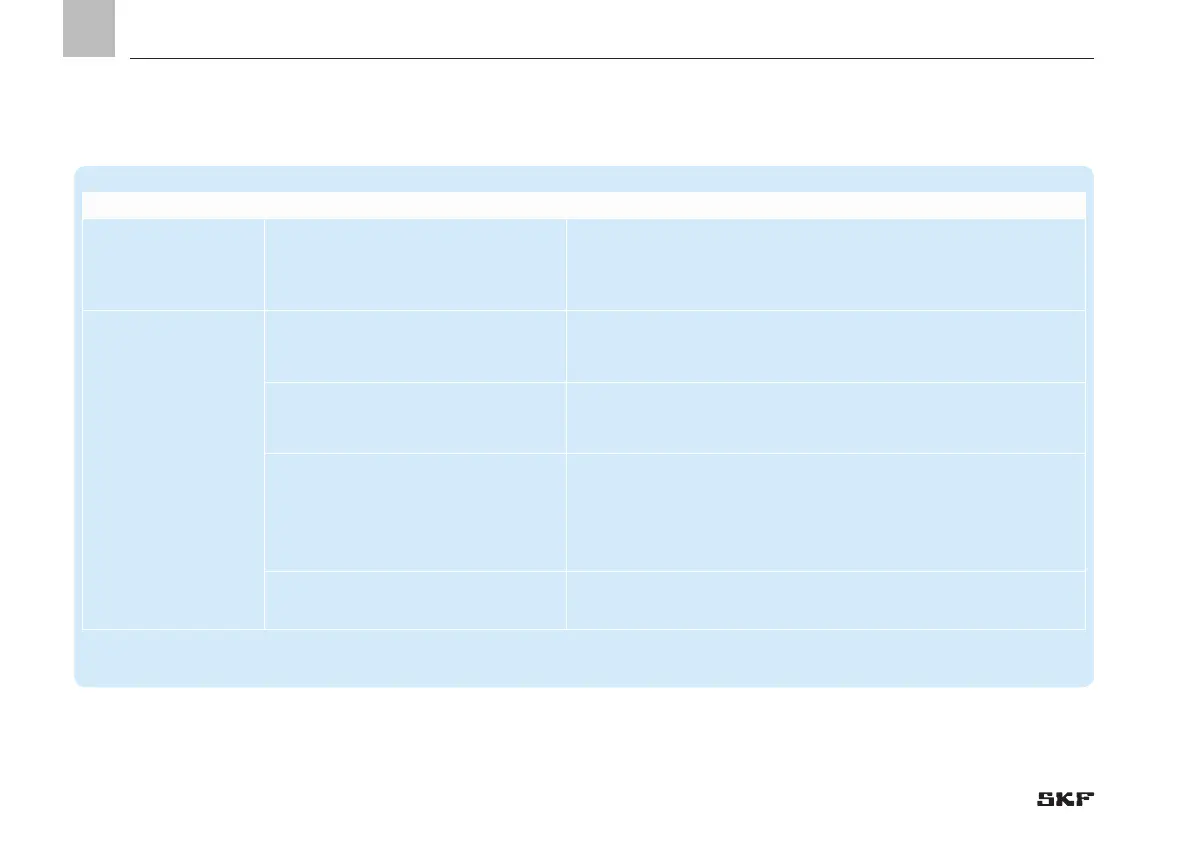

9. Malfunctions, causes, and remedies

EN

88

Malfunction Cause Remedy

Motor runs with

difficulty and at a low

speed

o Ambient temperature too low

(see “Technical Data,” Chapter 3)

o Aged grease, motor is overloaded

o Motor circuit breaker has tripped

• Increase ambient temperature

• Replace grease

• Identify and resolve cause

Pump does not convey

lubricant; no pressure

build-up

o Pump jammed

• Measure motor current If current is impermissibly high:

• Dismantle pump, crank by hand:

• If resistance is high, replace the pump.

o Motor jammed

• Measure motor current If current is impermissibly high:

• Dismantle motor, crank by hand:

• If resistance is high, replace the motor.

o

Incorrect rotational direction of motor

• Check pressure-regulating valve to make sure that opening

pressure is correct and that there is no contamination or damage

• If opening pressure is incorrect or if the pressure-regulating valve

is damaged, replace the valve. Only use original SKF spare parts.

• If contaminated, clean the pressure-regulating valve

o or check valve on pump element

defective or filter clogged

Loading...

Loading...