121

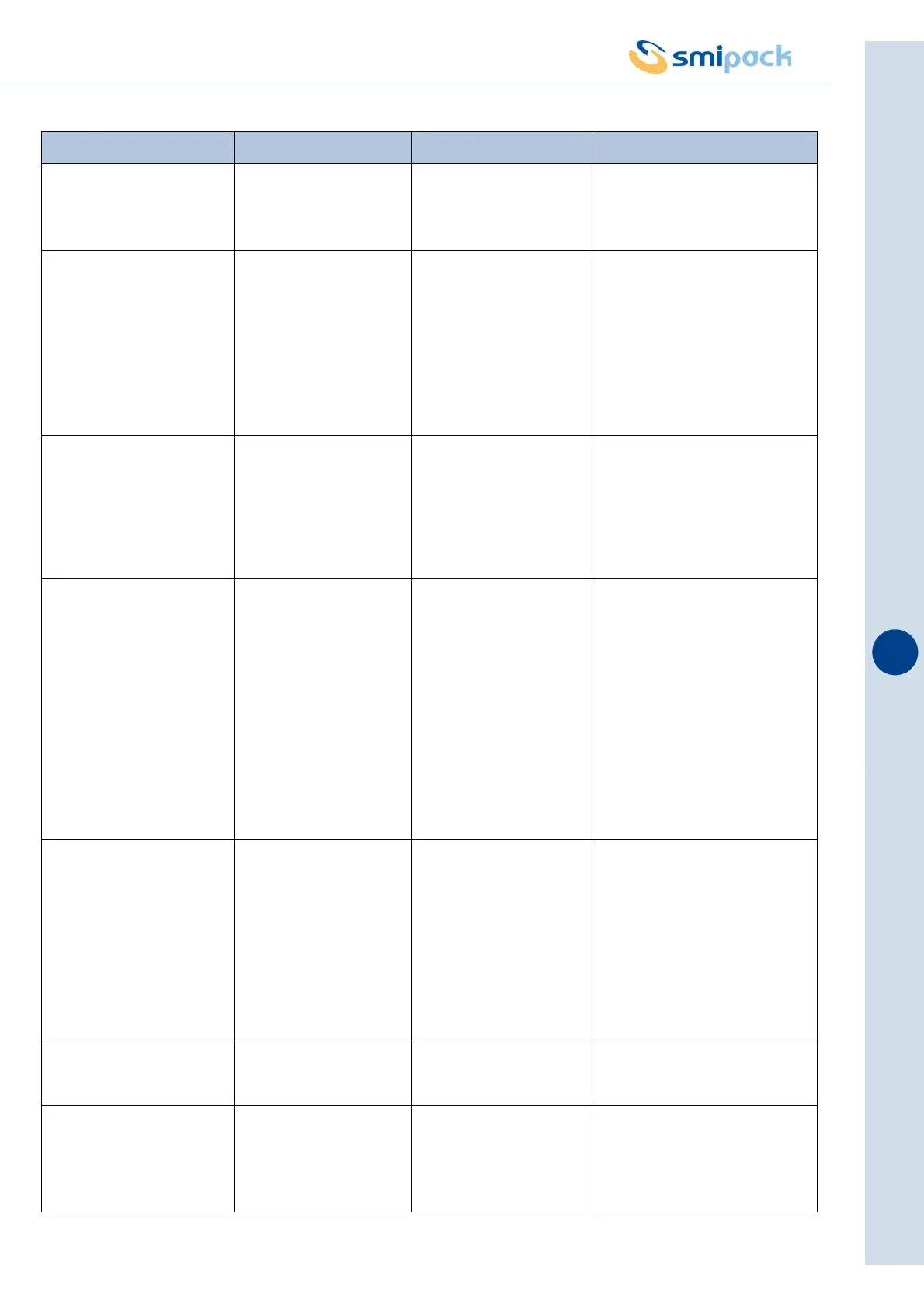

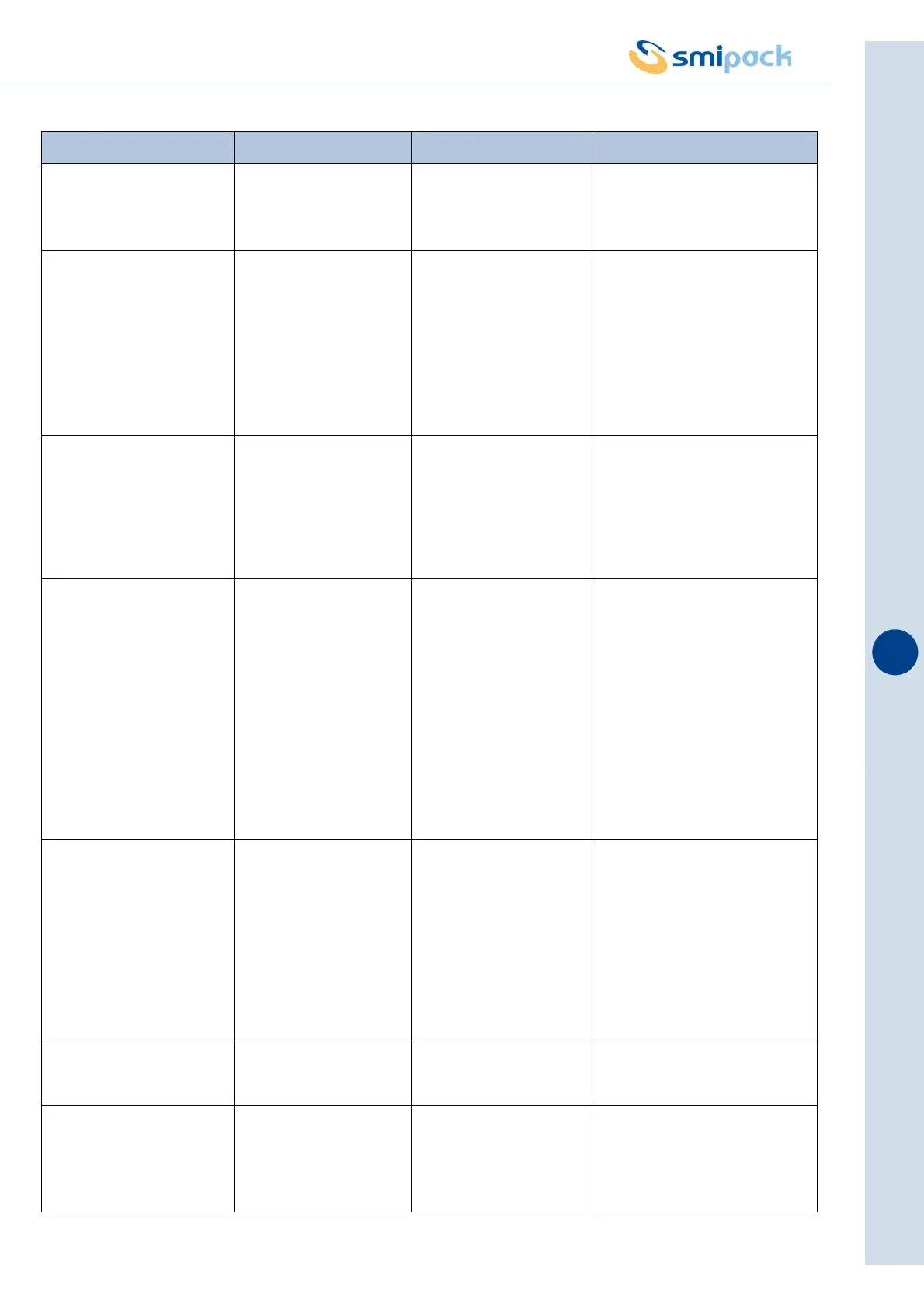

PROBLEM CAUSE CONSECUENCES SOLUTION

EXCESSIVE FLOW

The products to be

packed are too close

together.

A signal it is present that

does not cause a

stoppage of the

machine.

Increase the distance between

the products in the machine

infeed.

UNWINDER PROBLEM

The film unwinding

system is not working

correctly.

The machine goes into

alarm conditions when

the reel unwinder motor

stays on for too long.

Make sure the film is unwinding

correctly.

Check the closed position of the

lever located on the reel holder.

Verify that the tensioning bars

are working correctly.

OPEN UNWINDER

The movable hatch on

the reel holder is not

closed properly.

The automatic functions

of the machine are

disabled.

Close the movable hatch on the

reel holder.

Check the lever on the reel

holder is in the position at

which the contrast roll is

closed.

BAR MOVEMENT

PROBLEM

Anomalous movement

of the sealing bar has

been detected or the

sealing bar does not

move.

- Problems with the

sealing bar safety

sensors.

- An obstruction has

hindered the sealing

bar during operation.

- Malfunction on the

encoder signal.

- Problems of motor

operation.

- Make sure there are no

foreign objects blocking the

movement of the sealing

bar.

- Check that the mechanical

parts that allow the

movement of the sealing bar

do not impede its proper

functioning.

- Check the right functioning

of the inverter 16.U.1, the

motor and the encoder

signal 18.E.1.

BAR UNDERTEMP

[BAR

UNDERTEMPERATURE]

The sealing bar is not

able to reach the set

temperature.

The problem may be due

to low voltage.

Temperature problems

with the probe.

Check the working order of the

sealing bar and correct

temperature control. (check the

14.TC.1 thermocouple of the B1

element and the 14.TC.2

thermocouple of the B2

element).

Check the working order of the

resistor.

SEALING BAR

OBSTRUCTION

[OPTIONAL]

Detected an obstruction

in the sealing bar zone.

The sealing bar does not

move.

Remove the obstruction.

MOVABLE BELT PROB.

[MOVABLE BELT PROBLEM]

An operational problem

with the conveyor belt

approach system has

been detected.

The machine stops.

Check the mat's mechanisms

are not blocked.

Check the working order of the

movable mat's sensor, 24.SQ.1

Loading...

Loading...