EXCITE + - Crossover: Technical Service guide- Ver. 4.1

Pagina 7.48

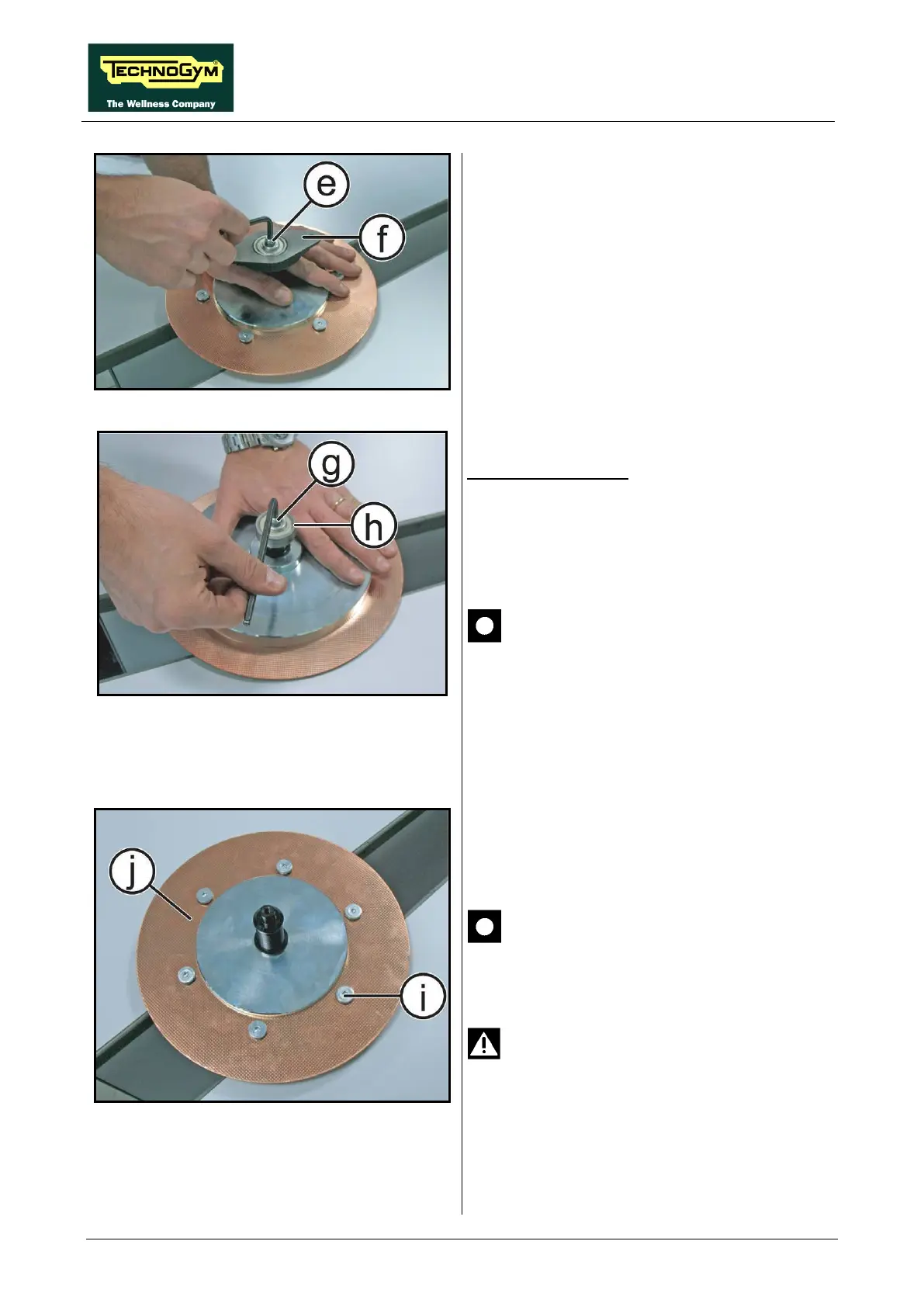

Figure 7.17-5

7. Back off the screw (e)

hexagonal wrench.

8. Remove the support plate (f).

Figure 7.17-6

On the opposite side:

9. Remove the support plate.

10. Back off the screw (g)

hexagonal wrench.

11. Remove the bearing (h).

CAUTION: During the reassembly

lock down the screws (e) and (g) using

a torque wrench set for 9Nm.

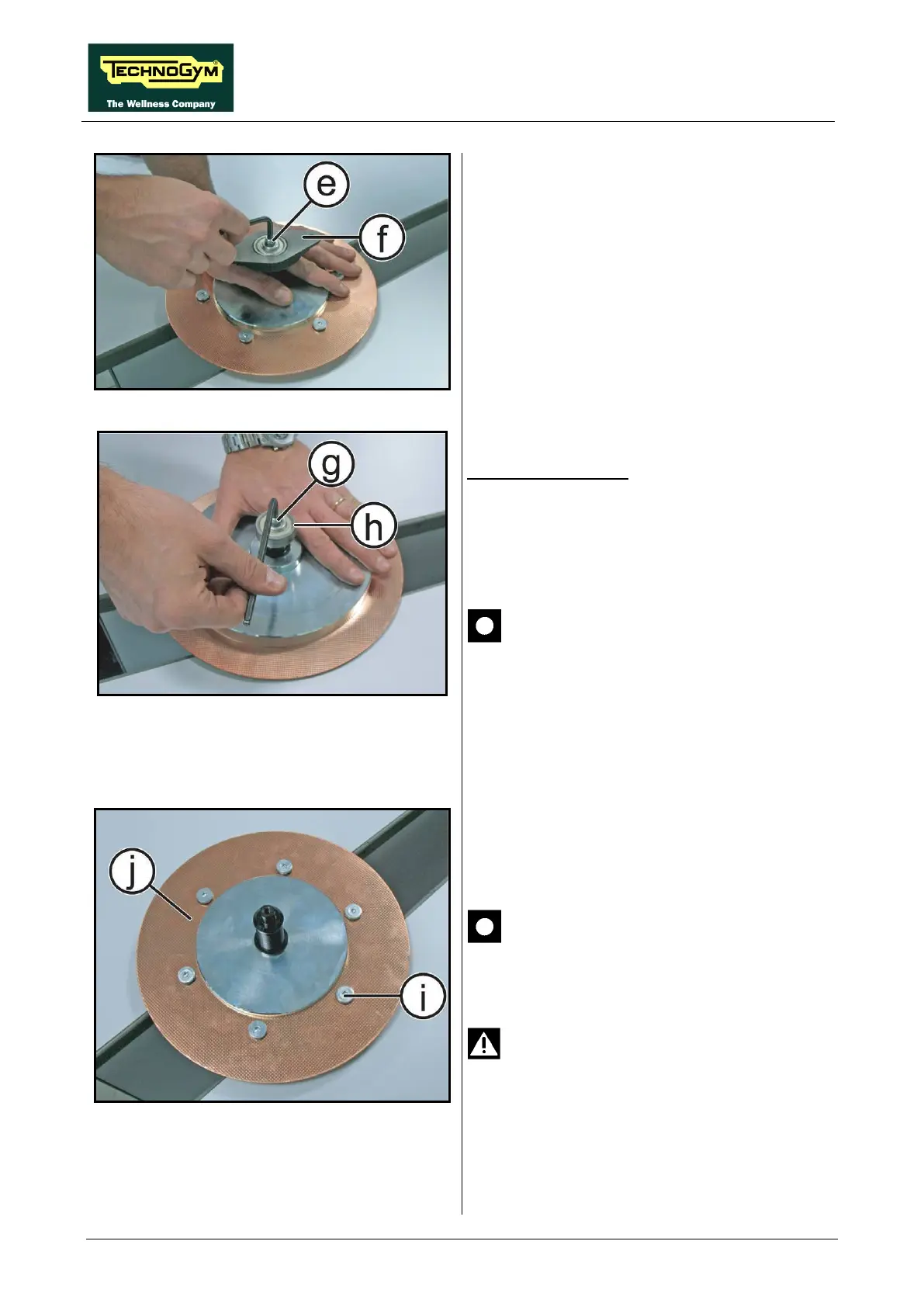

Figure 7.17-7

12. Back off the 6 screws (i) using a 4mm

hexagonal wrench.

13. Remove the copper disk (j)

necessary.

To reassemble the flywheel group, carry out the

above steps in reverse order.

CAUTION: During reassembly, lock

down the screws (i) using a torque

wrench set for 6Nm.

Take

particular care with the copper

disk, as it bends easily and may then

cause problems after reassembly, by

brushing against the winding block.

Measure with a flatness comparator to

check the copper disk flatness, the

permissible margin is

0.15 mm.

Loading...

Loading...