Note:Ifelectricalproblemsexistwithasolenoidvalvecoil,afaultmayhave

occurredthatwouldbeindicatedbyafaultcodeontheInfoCenterdisplay.

Beforeconsideringthatsolenoidvalvecoilserviceworkisnecessary,check

foranyexistingfaultcodes.

TestingtheHydraulicSolenoidValveCoils

Note:Beforeyoudisconnectthesolenoidvalvecoils,testthesolenoidsand

theircircuitwiringasTECoutputswiththeInfoCenterdisplay;refertoUsingthe

InfoCenterDisplayforTroubleshooting(page7–28).IftheInfoCenterveries

thatthesolenoidcoilsandcircuitwiringarefunctioningcorrectly,thennomore

testingisnecessary.

1.Parkthemachineonalevelsurface,lowerthecuttingunits,shutoffthe

engine,settheparkingbrake,andremovethekeyfromthekeyswitch.

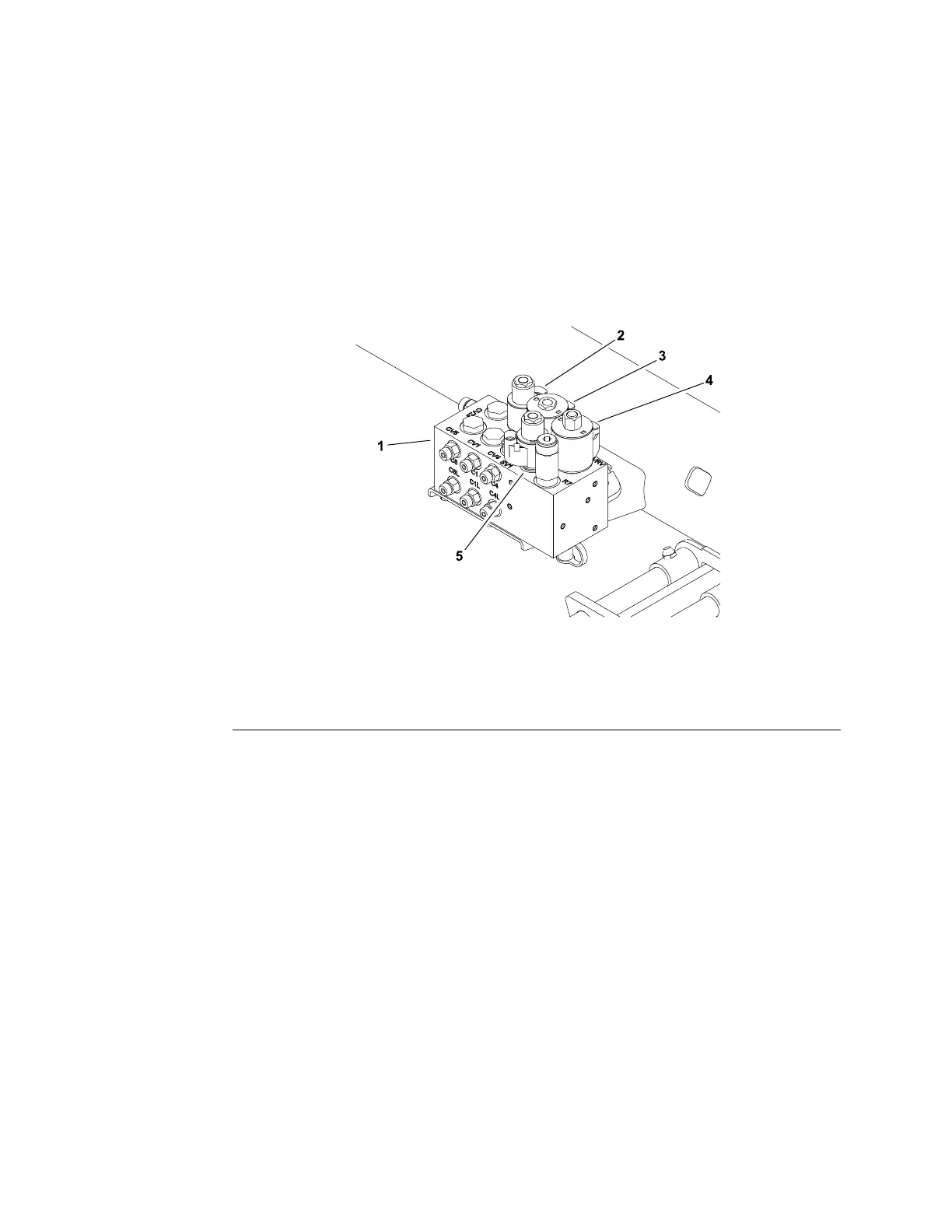

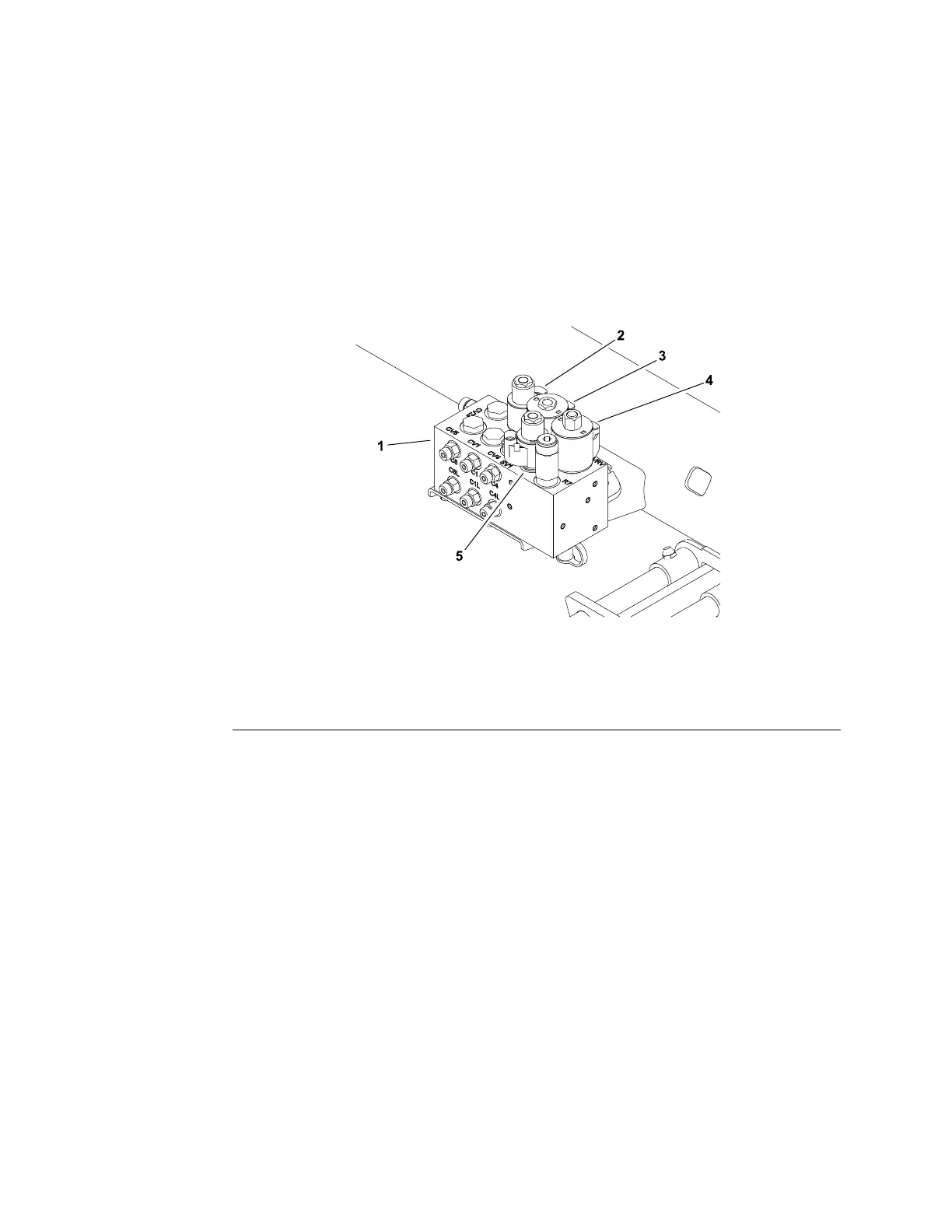

g214066

Figure265

1.Liftcontrolmanifold4.SVRVsolenoid

2.SV3solenoid5.SV1solenoid

3.SV2solenoid

2.Togetaccesstothemowcontrolmanifold,raiseandsupporttheoperator

seat(Figure264).Togetaccesstotheliftcontrolmanifold,removethe

operatoroorplate(Figure265).

3.Identifythecoilbymeasuringtheheightanddiameterofthecoil.

4.Disconnectthewireharnessconnectorfromthehydraulicsolenoidvalve

coilthatistobetested.

Note:Beforetakingthesmallresistancereadingswithadigitalmultimeter,

shortthemultimetertestleadstogether.Themultimeterdisplaysasmall

resistancevalue(usually0.5ohmsorless).Thisresistanceisbecauseofthe

internalresistanceofthemultimeterandtestleads.Subtractthisvaluefrom

themeasuredvalueofthecomponentthatyouaretesting.

Note:Thesolenoidcoilresistanceshouldbemeasuredwithsolenoidat

approximately20°C(68°F).Resistancemaybeslightlydifferentthanlisted

atdifferenttemperatures.Typically,adamagedsolenoidcoilwilleitherbe

shorted(verylowornoresistance)oropen(inniteresistance).

5.Useamultimeter(ohmssetting),measuretheresistancebetweenthe2

connectorterminalsonthesolenoidcoil.Theresistanceforthesolenoidcoils

isidentiedintheSolenoidValveCoilSpecicationsT able(page7–97).

ElectricalSystem:TestingtheElectricalComponents

Page7–96

Reelmaster

®

5410/5510/5610Series

15216SLRevC

Loading...

Loading...