Groundsmaster 4100--D/4110--DPage 5 -- 38Electrical System

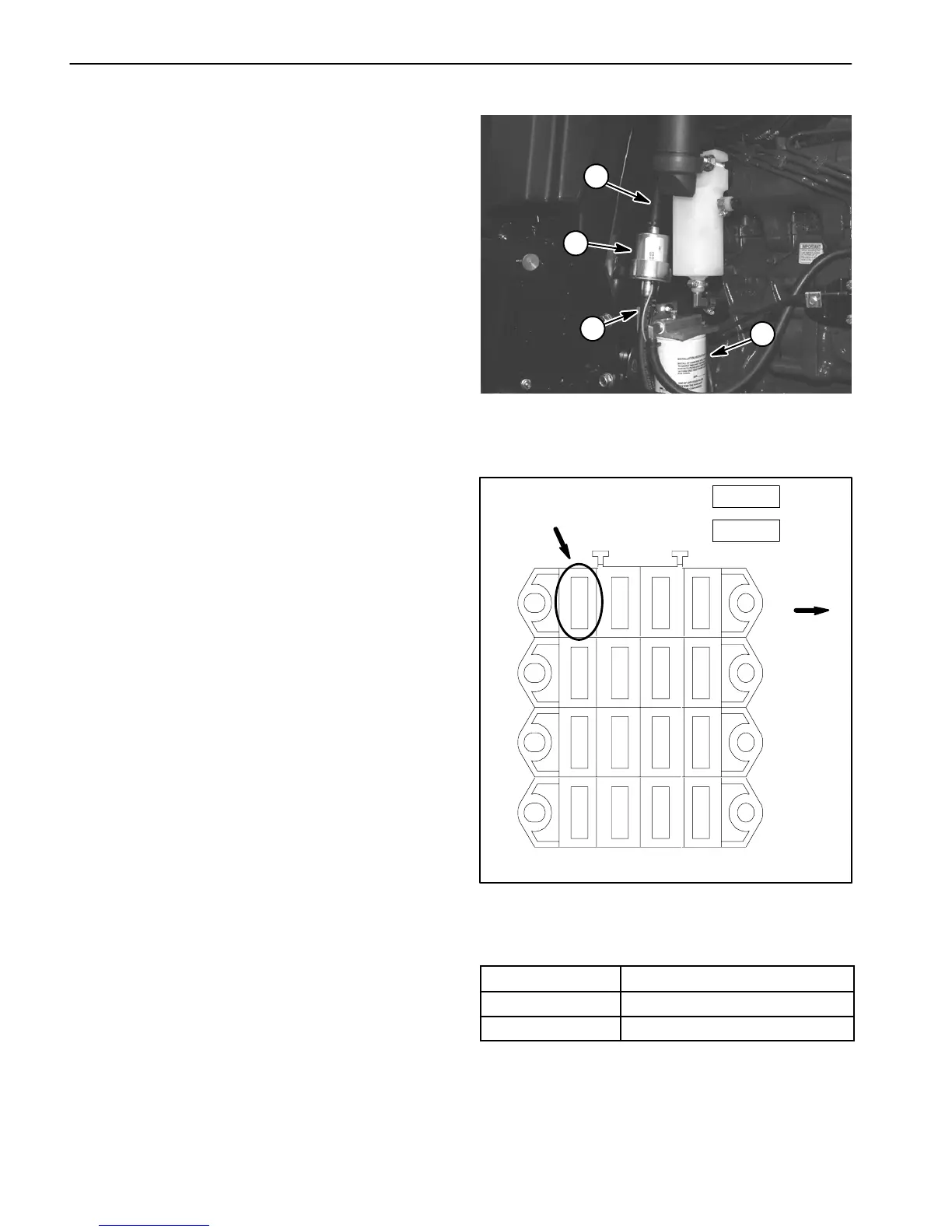

Fuel Pump

The fuel pump is attached to the frame above the fuel

water separator (Fig. 48).

Operational Test

1. Park machine on a level surface,lowercuttingdeck,

stopengineandapplyparkingbrake.Raiseandsupport

hood.

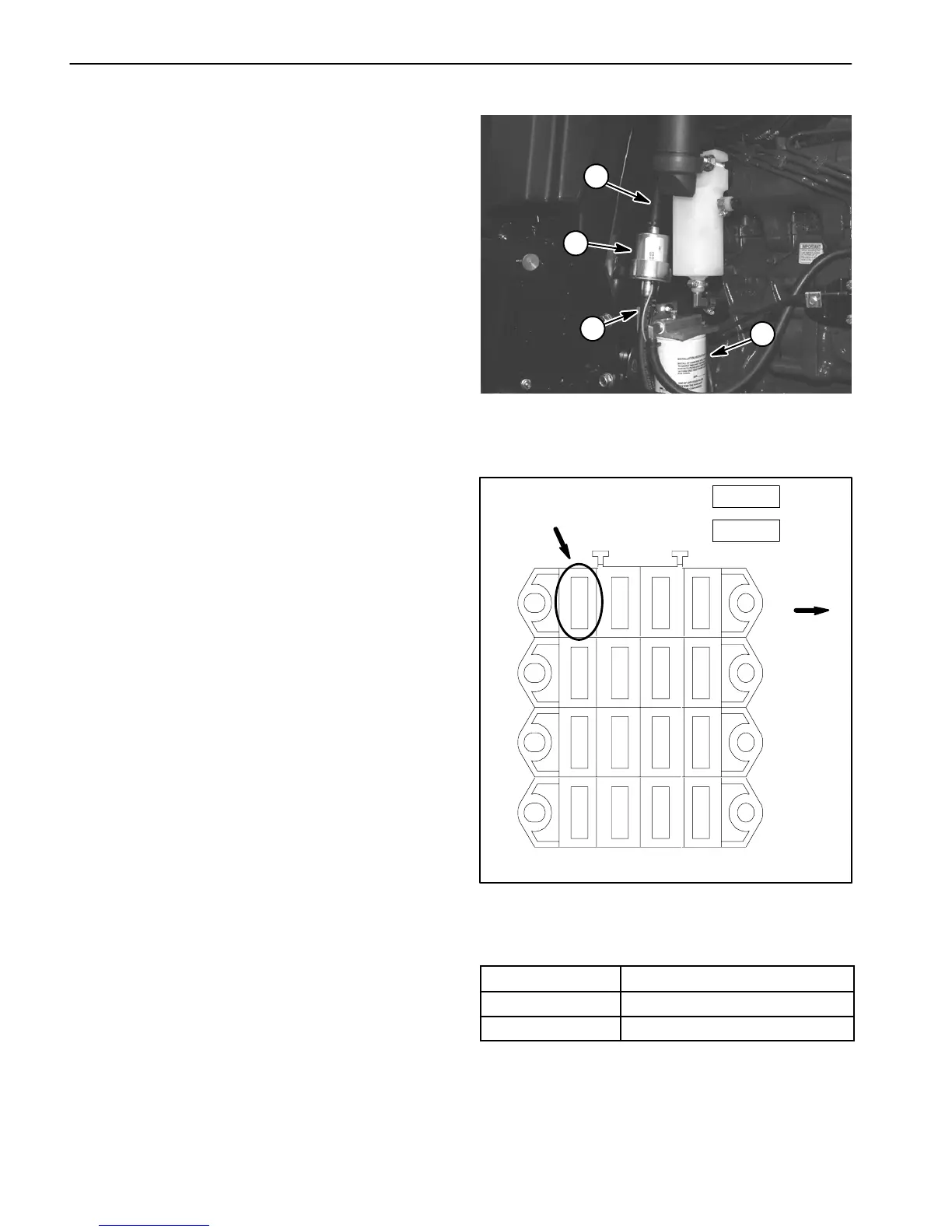

2. RemovefuseF1--1(20A)(Fig.49)fromfuseblockto

prevent the engine from cranking.

3. Disconnectfuelhose(pumpdischarge)fromthefuel

water separator.

4. Make sure fuel hoses attached to the fuel pump are

free of obstructions.

5. Place fuelhose(pump discharge) into a large, grad-

uated cylinder sufficient enough to collect 1 quart (0.95

liter).

6. Collect fuelin the graduated cylinder by turningigni-

tion switch to the ON position. Allow pump to run for fif-

teen (15) seconds, then turn switch to OFF.

7. The amount of fuel collected in the graduated cylin-

der should be approximately 16 fl oz (475 ml) after fif-

teen (15) seconds.

8. Replace fuel pump as necessary.Installfuel hose to

the water separator.

9. Install fuse F1--1 (20A) into fuse block.

10.Prime fuel system.

1. Fuel water separator

2. Fuel pump

3. Pump inlet hose

4. Pump discharge hose

Figure 48

2

1

3

4

Figure 49

F1

F2

1234

F3

F4

FRONT

2A

7.5 A

7.5A

7.5A

2A

7.5A

7.5A

7.5A

OPTION

10A

10A

10A

20A

OPTION

M1 (60A)

M2 (60A)

FUSE F1--1

10A

10A

Fuel Pump Specifications

Pump Capacity

64 fl oz/min (1.9 l/min)

Pressure 7 PSI (48.3 kPa)

Current Draw 2.0 amp

Loading...

Loading...