Groundsmaster 4100--D/4110--DPage 5 -- 42Electrical System

Wing Deck Position Switches

Two (2) wing deck position switches are used on the

Groundsmaster 4100--D and 4110--D as inputs for the

TEC--5001 controller. The position switches are pow-

ered proximity switches that are normally open. The

switchesincorporateaninternalreedswitchandaLED.

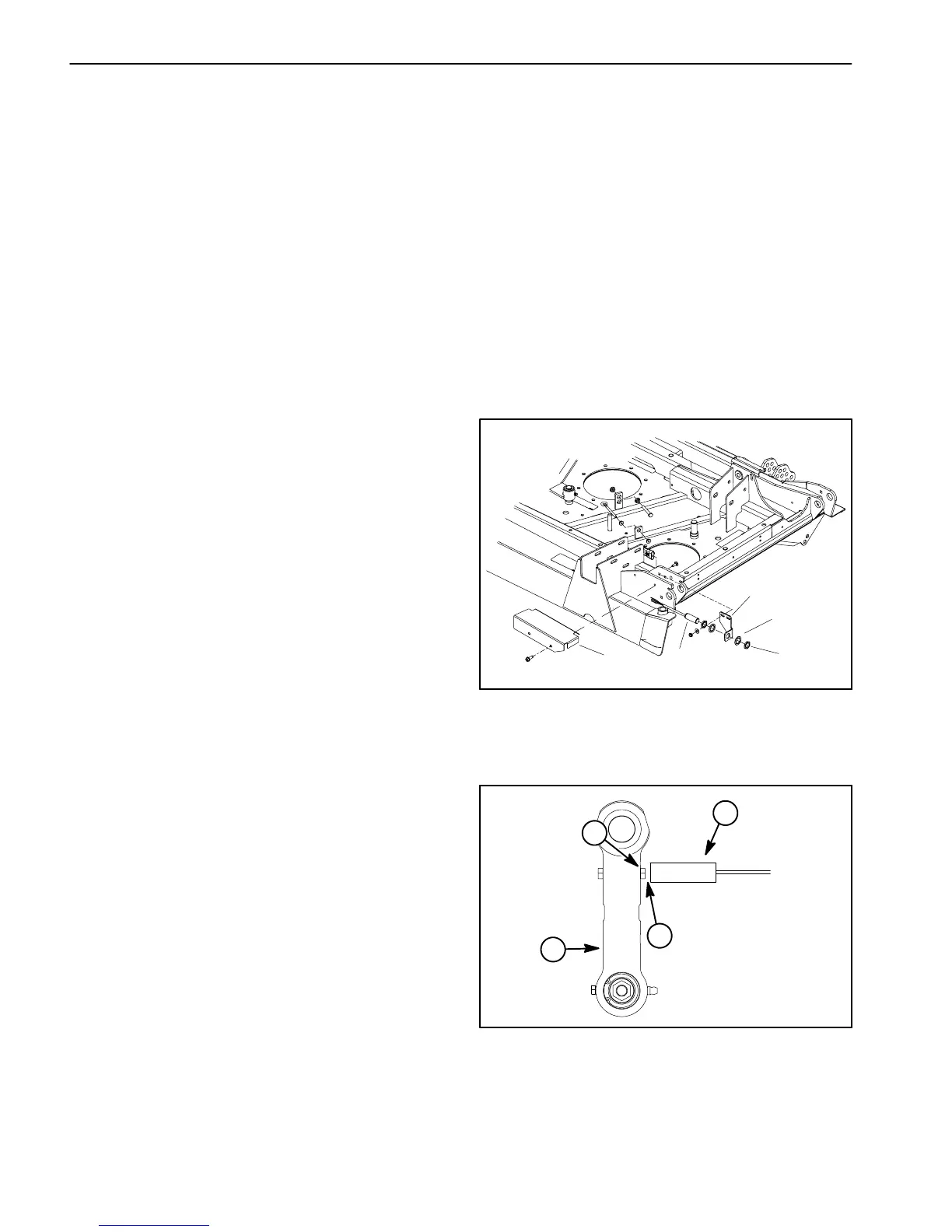

Theseswitches are secured to thecenter section of the

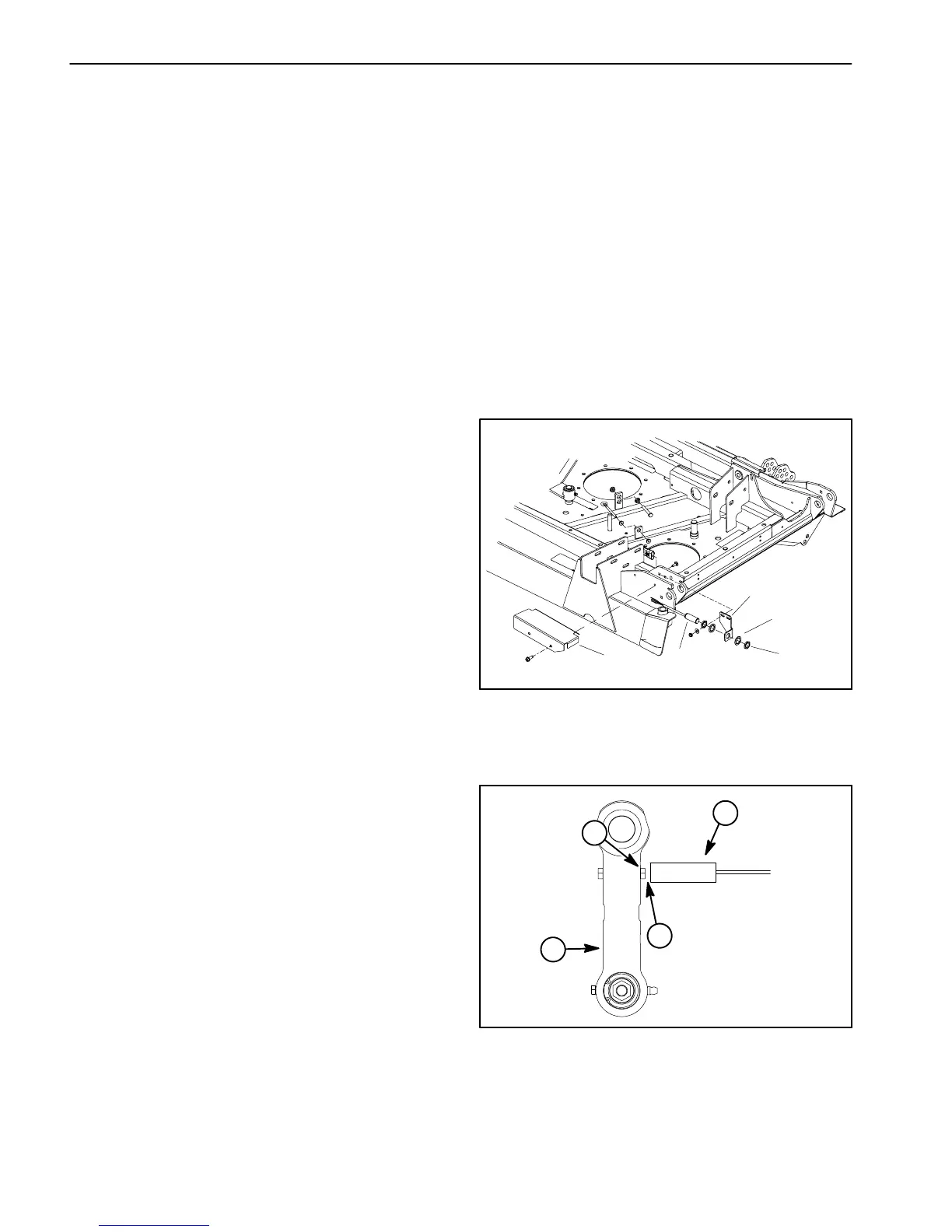

cutting deck (Fig. 55). A bolt head on the wing deck link

is the sensing plate for the position switch (Fig. 56).

Whenawing deck is lowered, the bolt head on the wing

decklink is positionedcloseto thepositions witch caus-

ing the switch to close. The closed switch provides an

inputfortheTEC--5001controllertoallowwingdeckop-

eration.Whenawingdeckisraised,theboltheadonthe

wing deck link is moved away from the position switch

sotheswitchisinitsnormallyopenstate.Theopenposi-

tionswitchpreventswingdeckoperationwhen thewing

deck is raised.

Testing

1. The cutting deck position switches and their circuit

wiring should be tested as a TEC--5001 input with the

Diagnostic Display (see Diagnostic Display in the Trou-

bleshooting section of this chapter). If the Diagnostic

Displayverifiesthatthepositionswitchesandcircuitwir-

ing are functioning correctly,no further switch testing is

necessary. If, however, the Display determines that a

positionswitchandcircuitwiringarenotfunctioningcor-

rectly, proceed with test.

2. Park machine on a level surface, lower cutting deck

(including wing decks), stop engine and apply parking

brake. Remove switch cover from deck to allow access

to switch that requires testing (Fig. 55).

3. Turn ignition switch to the ON position (do not start

engine) and check LED on cable end of position

switches. LED should be illuminated when the wing

decks are fully lowered.

4. Startengine,fullyraisewingdecksandthenstopen-

gine.Then,turnignitionswitchtotheONposition(donot

start engine) and check LED on cable end of position

switches.LEDshouldnotbeilluminatedwhenthewing

decks are fully raised.

5. Lower wing decks and then stop engine.

6. If a position switch LED did not function correctly:

A. MakesurethatignitionswitchisOFFanddiscon-

nect the switch connector from deck wire harness.

B. Using a multimeter, verify that wire harness con-

nector terminal for pink wire has 12 VDC when the

ignition switch is ON.

C. Make sure that gap between end of position

switchandboltheadonwingdecklinkwhenthew ing

deck is lowered is from 0.070” to 0.130” (1.8 to 3.3

mm) (Fig. 56).

D. Ifpinkwirehassystemvoltagepresentandgapis

correctbutswitchLEDdidnotfunction,replaceposi-

tion switch.

7. After testing iscomplete,make sure thatswitch con-

nector is plugged into deck wire harness. Install switch

cover to deck.

1. Switch cover

2. Position switch

3. Switch bracket

4. Lock washer (2 used)

5. Jam nut (2 used)

Figure 55

1

2

3

4

5

1. Position switch

2. Bolt head

3. Wing deck link

4. Gap location

Figure 56

1

2

3

4

Loading...

Loading...