Groundsmaster 4100--D/4110--D Cutting DeckPage 8 -- 11

Removal (Fig. 6)

1. Position machine on a clean, level s urface. Lower

cutting deck and engage parking brake.

2. Fully raise wing deck, stop engine and remove key

fromthe ignition switch. Remove three(3) washerhead

screws and shield strap that secure flex shield to wing

deck. Lower wing deck.

3. Remove hydraulic motor from wing deck (see Cut-

ting Deck Motor Removal in the Service and Repairs

Section of Chapter 4 -- Hydraulic System).

4. Removecapscrewandlocknutthatsecureliftcylin-

der clevis to the wing deck (Fig. 7).

5. Remove switch shield (item 50) from center deck.

6. Support wing deck to prevent it from falling as links

are removed.

7. Remove capscrew(item29)frompivotpinonupper

endofbothlinks.Capscrewonrearlink also uses a flat

washer (item 28).

NOTE: Whenremovingpivotpinsfromdeck,noteloca-

tion of thrust washers (item 6) and hardened spacers

(item 42) for assembly purposes.

8. Remove flangenut (item19) fromcarriage bolt(item

26) and pull pivot pins (item 18) from deck. Locate and

retrieve thrust washers (item 6) and hardened spacers

(item 42) from between links and deck brackets.

9. Slide the wing deck away from the center deck.

10.If required,removelink(s) from wing deck by remov-

ing lock nut and flat washer that secure tapered stud to

deck. Press tapered stud from deck to remove link as-

sembly. Remove foam washer (item 42) and link skid.

Installation (Fig. 6)

1. Parkmachineonaclean,levelsurface.Stopengine,

engageparkingbrakeandremove key from the ignition

switch.

2. If links were removed from wing deck, thoroughly

clean tapered stud on link and mounting boss of wing

deck. Place foam washer on tapered stud and insert

studintodeckmountingboss.Makesurethatplug(item

40) is orientated toward wing deck and grease fitting

(item41)istowardcenterdeck.Positionlinkskidtostud

andsecurewithflatwasherandlocknut.Torquelocknut

from 160 to 180 ft--lb (217 to 244 N--m).

NOTE: Pivot latches (item 8) may need to be manually

openedpriortow ing deck installation. If necessary,use

a pry bar to carefully open latch.

3. Position the wing deck to the center deck.

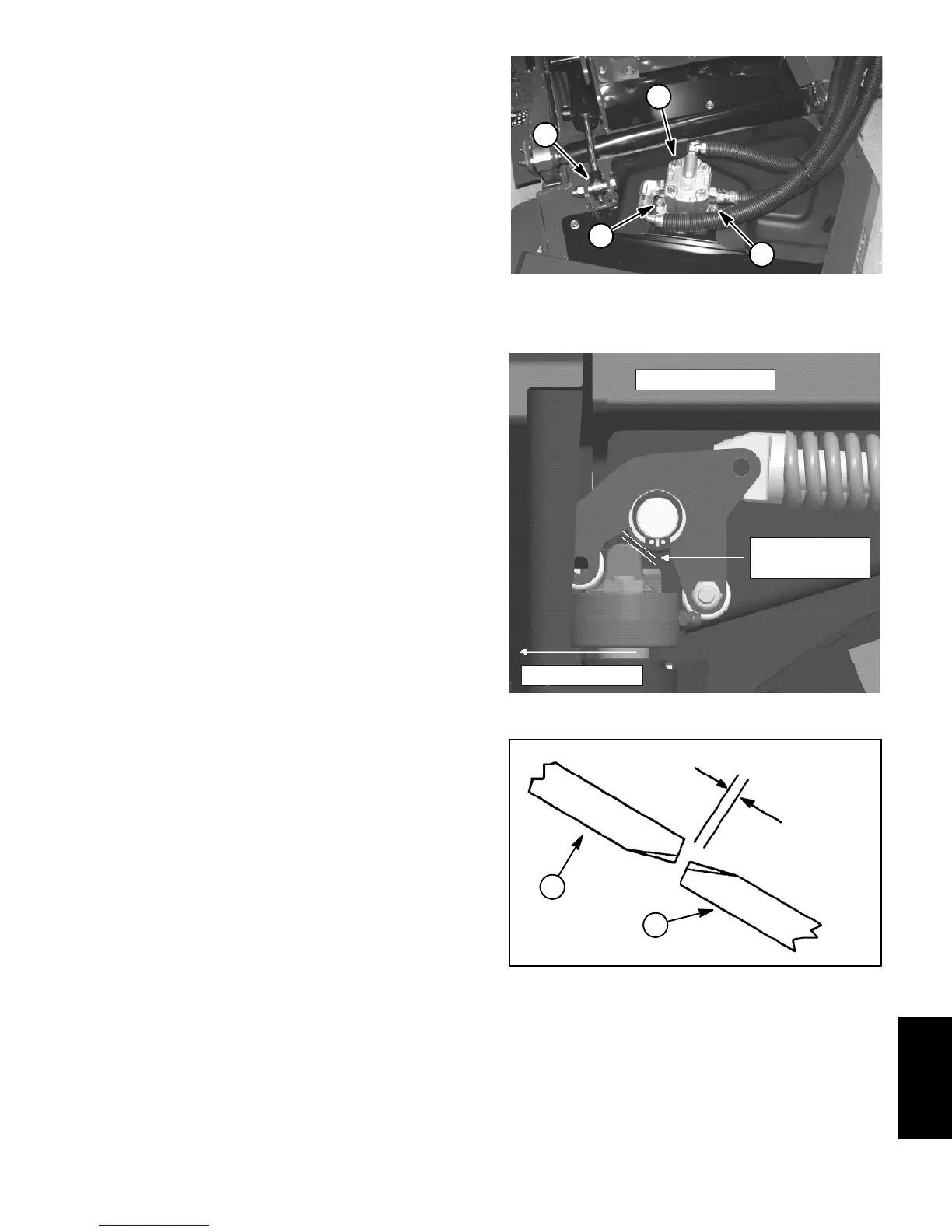

1. Hydraulic motor

2. Flange head screw

3. Lift cylinder clevis

Figure 7

1

2

2

3

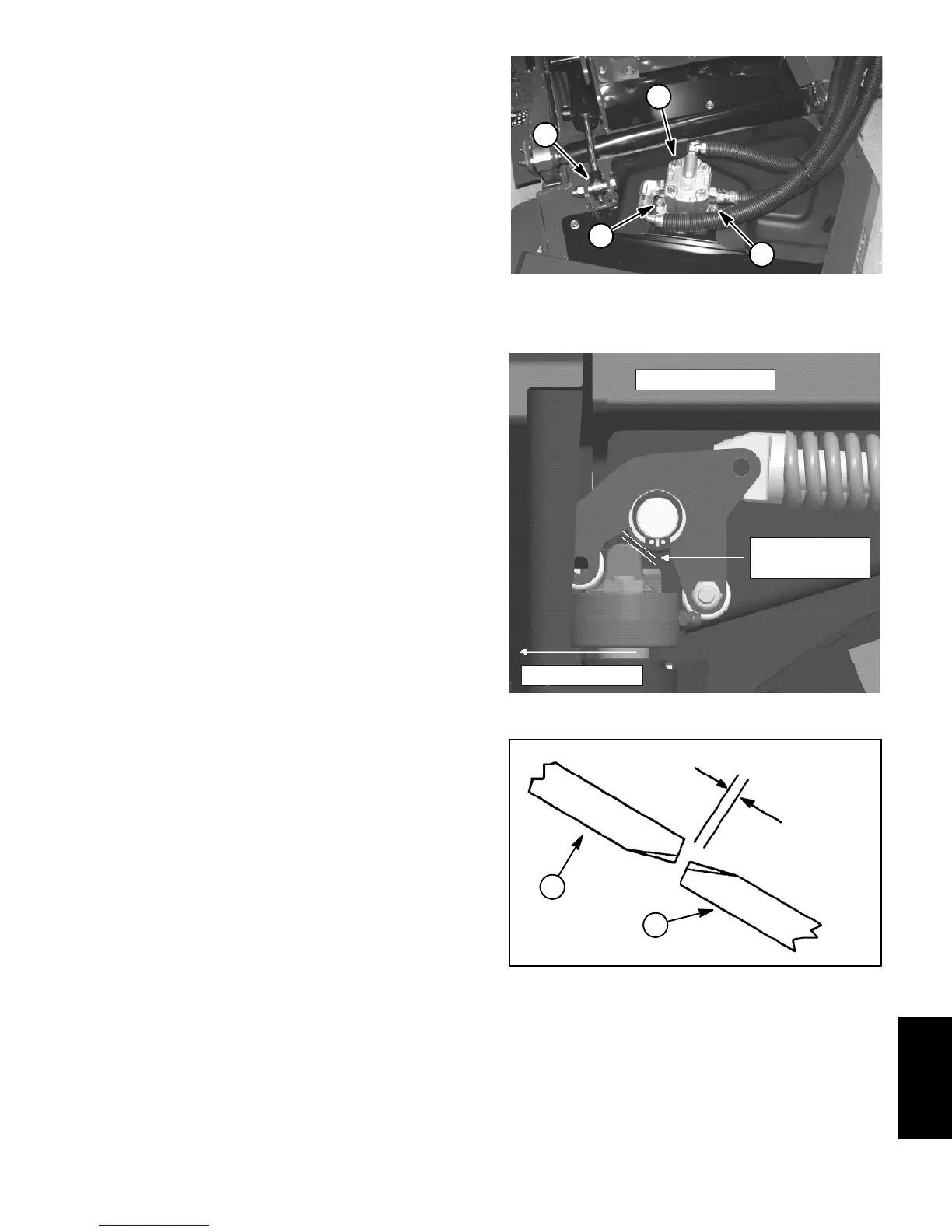

Figure 8

Front of center deck

Wing opens this way

0.060” to 0.090”

(1.5 to 2.2 mm)

(wing lowered & latched)

1. Wing deck blade 2. Center deck blade

Figure 9

(9.7 to 15.7 mm)

0.380” to 0.620”

1

2

Cutting

Deck

Loading...

Loading...