Groundsmaster 4100--D/4110--D Page 3 -- 19 Kubota Diesel Engine

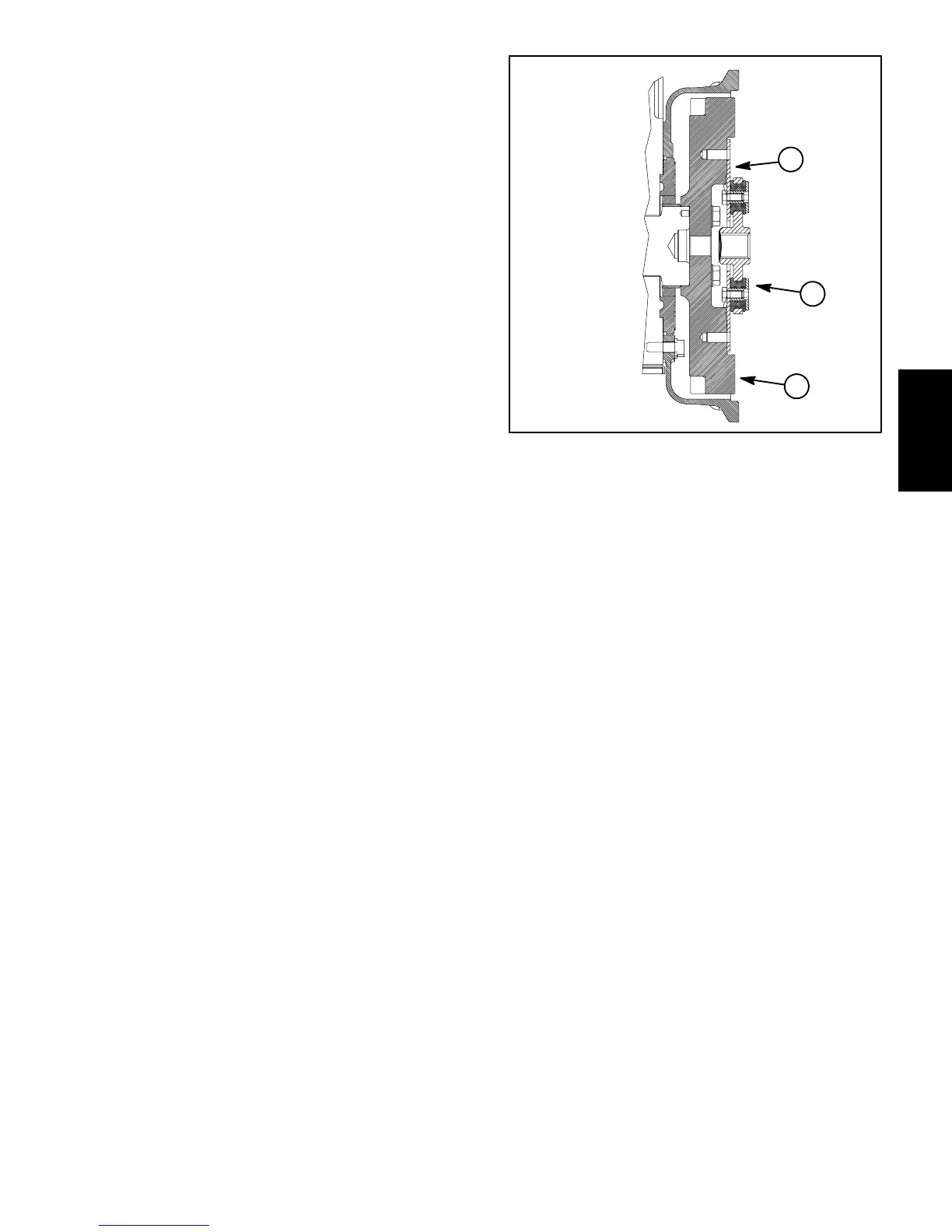

Coupler Removal (Fig. 17)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before coupler can be removed.

1. Ifengineisinmachine,supportenginefrombelowto

preventitfromshifting.Removehydraulicpumpassem-

bly(seePiston(Traction)Pump Removalinthe Service

and Repairs section of Chapter 4 -- Hydraulic System).

2. Remove flywheel plate and spring coupler from en-

gine using Figure 17 as a guide.

Coupler Installation (Fig. 17)

1. Position spring coupler to engine flywheel and align

mounting holes. Make sure that coupler hub is away

from engine flywheel (Fig. 18).

2. Apply Loctite #242 (or equivalent) to threads of cap

screws (item 3). Secure coupler to flywheel with six (6)

capscrewsandwashers.Torquecapscrewsinacross-

ing pattern from 29 to 33 ft--lb (40 to 44 N--m).

3. Positionflywheelplatetoengineandenginemounts.

Apply Loctite #242 (or equivalent) to threads of cap

screws (items 5 and 7). Secure flywheel plate and

mountswithcapscrews(items5and7)andwashersus-

ingacrossing pattern tightening procedure.Torquecap

screws in a crossing pattern from 28 to 32 ft--lb (38 to

43 N--m).

4. If engine is in machine, install hydraulic pump as-

sembly (see Piston (Traction) Pump Installation in the

Service and Repairs section of Chapter 4 -- Hydraulic

System).

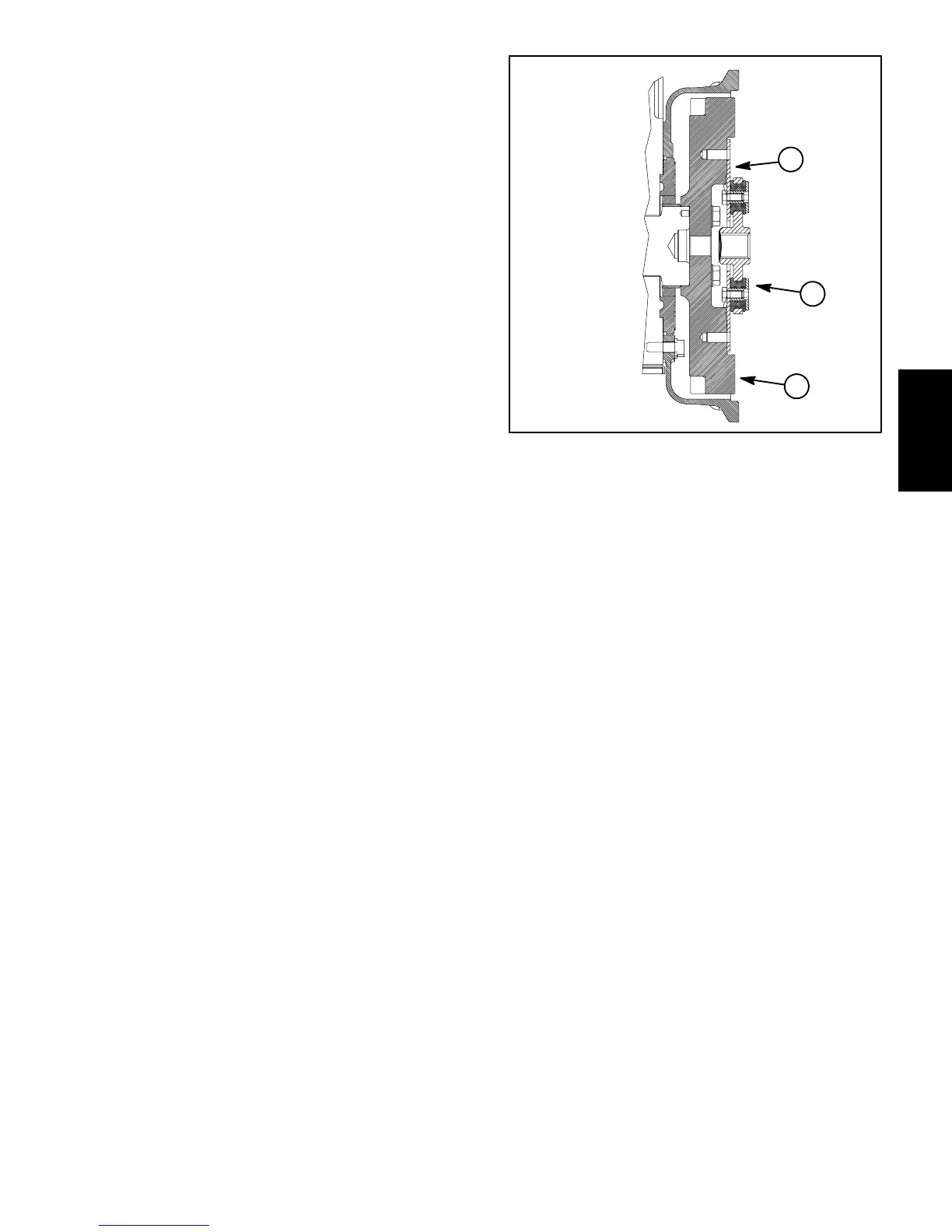

Figure 18

1. Spring coupler

2. Engine flywheel

3. Coupler hub

Engine Side Hydraulic

Pump Side

1

2

3

Kubota

Diesel Engine

Loading...

Loading...