5

© 2008 - 2011 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO2020C/2330C/2820C/2830C/3520C/3530C/4520C

PREVENTIVE MAINTENANCE (PM)

5 - 21

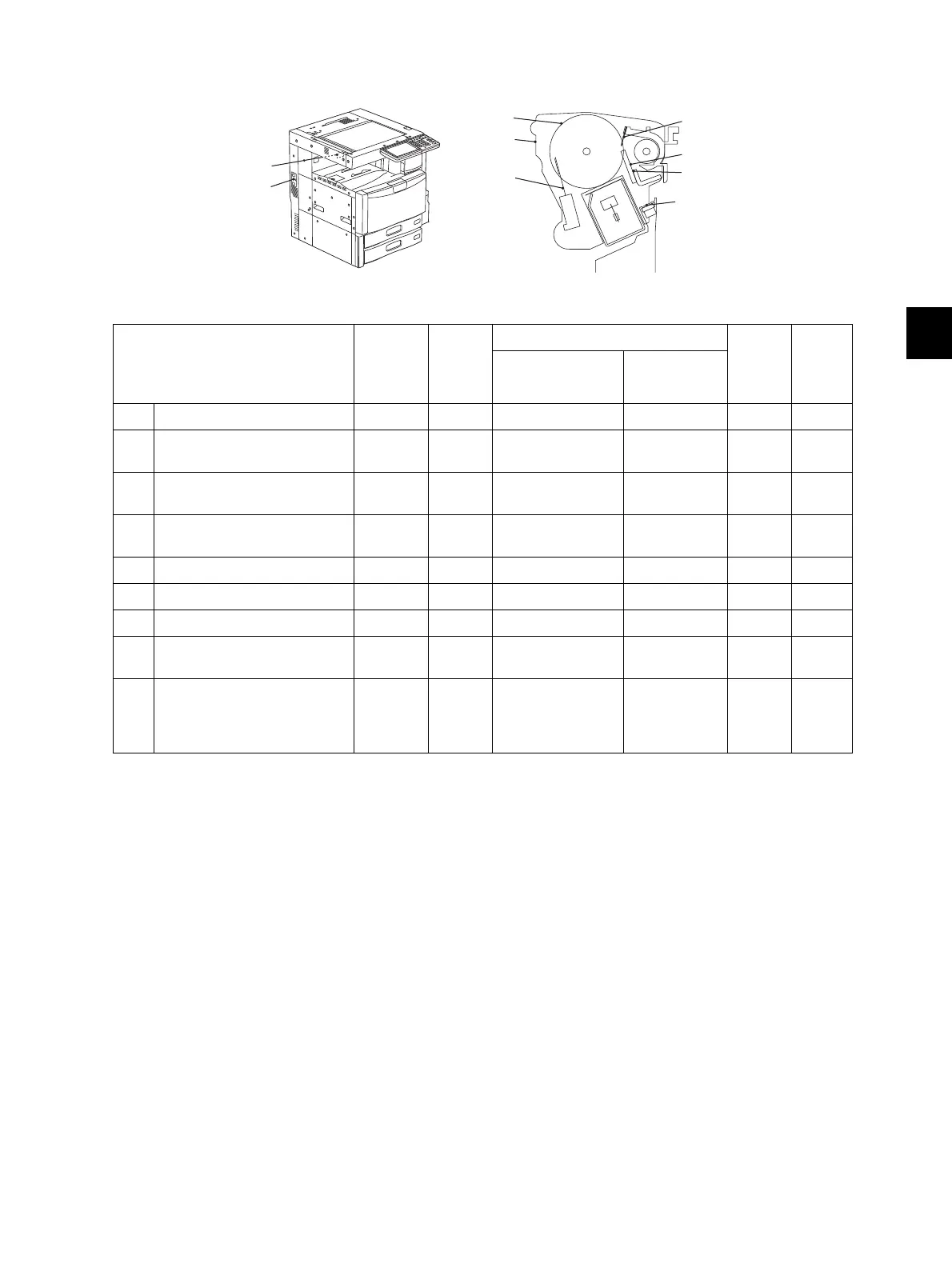

5.6.7 Drum/Cleaner unit, Cleaner related section

Fig. 5-17

* G2: Drum

• Handling precautions

If fingerprints or oil adhere to the surface of the drum, its properties may degrade, affecting

the quality of the copy image. So, wear gloves to avoid touching the drum surface with your

bare hands. Be sure to handle the drum carefully when installing and removing it so as not to

damage its surface.

• Do not use “patting powder” (lubricant)

Since “patting powder” may affect the initial image if it adheres to the OPC surface, do not

apply it. The friction between the drum and cleaning blade is sufficiently small without it and

no problem would occur even if it is not applied.

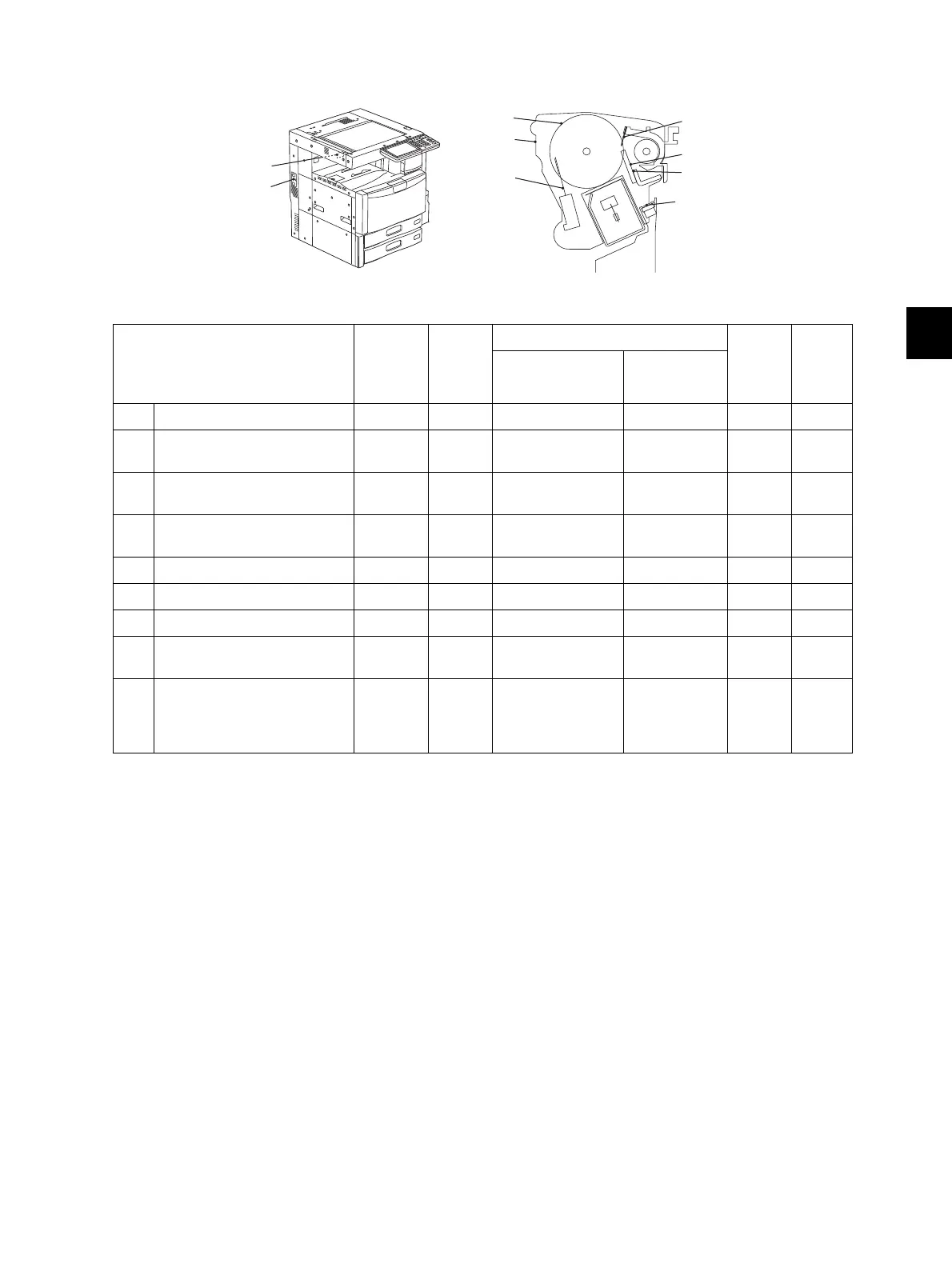

Items to check Cleaning

Lubric

ation/

Coatin

g

Replacement

Operati

on

check

Parts

list

<P-I>

(x 1,000 sheets)

(x 1,000 drive

counts)

G1 Whole cleaner unit B

G2 Drum 40/56/56/70/70

(40/46/56/56/70)

170

G3 Drum cleaning blade 40/56/56/70/70

(40/46/56/56/70)

170 39-16

G4 Felt B R R 39-19

39-20

G5 Recovery blade B 39-21

G6 Drum thermistor B 38-33

G7 Discharge LED B 36-19

G8 Ozone filter-1 40/56/56/70/70

(40/46/56/56/70)

170 1-13

G9 Ozone filter-2 160/224/224/280/

280

(160/184/224/224/

280)

680 7-36

G2

G4

G1

G3

G5

G7

G9

G6

G8

Loading...

Loading...