7-40 OM EZ17 us 1.0 * ez17w710.fm

7

7.11 V-belt

Checking V-belt condition and tension

Injury hazard due to rotating parts!

Rotating parts can cause serious injuries or death.

► Open the engine cover only at engine standstill.

Engine damage due to malfunctioning V-belt.

► Check V-belt condition and tension once a week.

► Have the V-belt only replaced by a Wacker Neuson service center.

1. Place the machine on firm, level and horizontal ground.

2. Stop the engine. See “Preparing lubrication”.

3. Remove the starting key and carry it with you.

4. Let the engine cool down.

5. Raise the seat (see chapter “Maintenance accesses”).

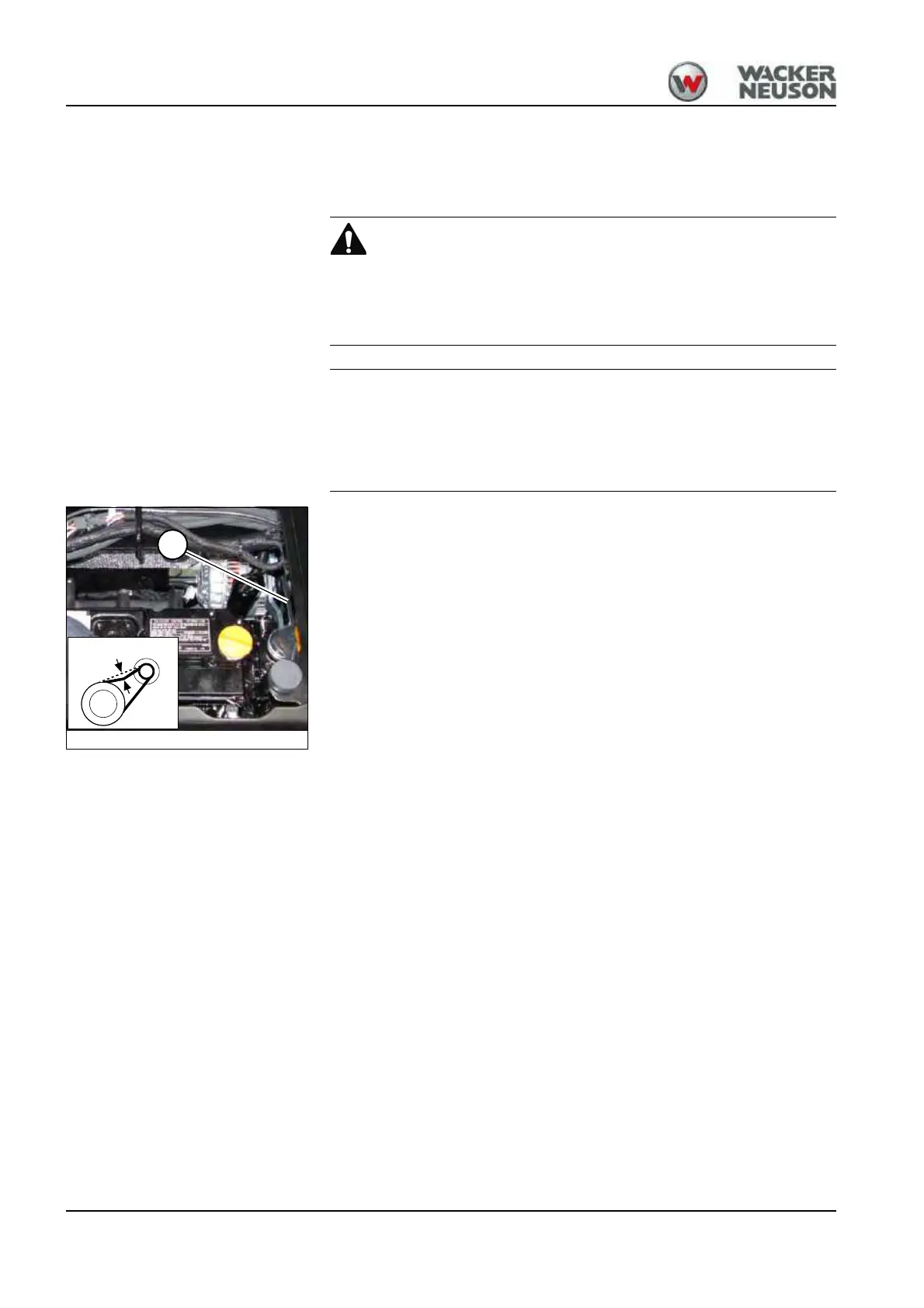

6. Carefully check V-belt A for damage, cracks, cuts, etc.

7. If the V-belt is damaged (cracks, wear, ruptures, etc.):

➥ Have the V-belt replaced by a Wacker Neuson service center.

➥ Replace the V-belt if it touches the base of the V-belt groove or if

the pulleys are damaged.

8. Press with your thumb about 100 N (22.5 lbf) to check the deflection of

the V-belt between the crankshaft disc and the fan wheel.

9. A new V-belt should have a deflection of 6 to 8 mm (0.24 to 0.31 in), a

used V-belt (after about 5 minutes running time) should have a

deflection of 7 to 9 mm (0.27 to 0.35 in).

10.If V-belt tension is not correct:

➥ Have the V-belt replaced or retightened by a Wacker Neuson

service center.

11.Lock the seat.

Fig. 208

About 8 mm (0.31 in)

A

Loading...

Loading...