OM EZ17 us 1.0 * ez17w710.fm 7-49

7

7. Remove the starting key and carry it with you.

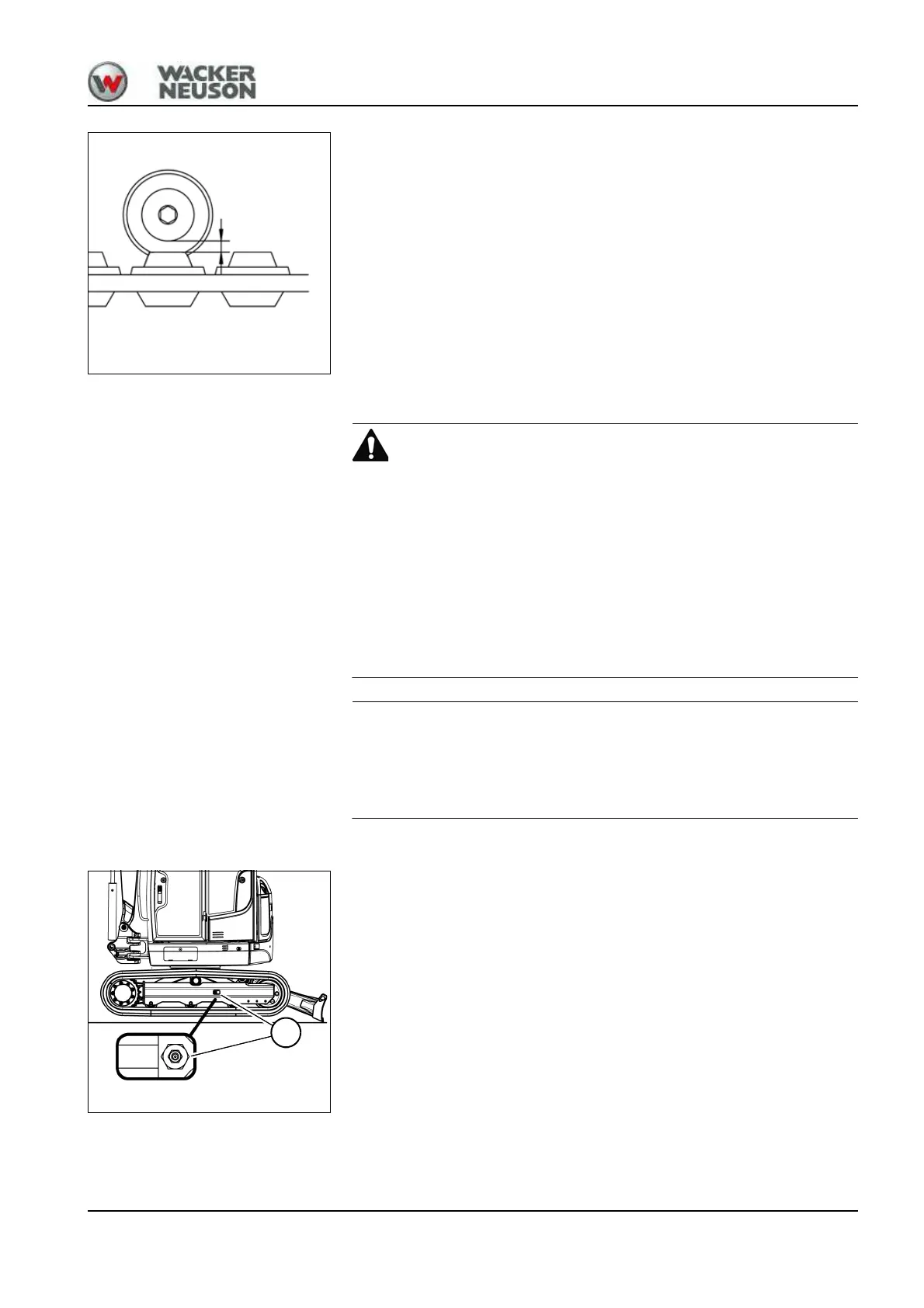

8. Adjust the correct track tension if the play between the track roller and

the track is not 20 – 25 mm (0.8 – 1 in).

Correcting track tension

Injury hazard due to grease escaping under pressure!

Grease escaping under pressure can penetrate the skin and cause

serious injuries or death.

► Open the lubricating valve only very carefully and do not unscrew it

more than a revolution.

► Wear protective gloves and safety glasses.

► Release grease only as described below.

► Contact a Wacker Neuson service center if this does not reduce track

tension.

Damage to tracks due to overtightening. This causes severe damage to

the hydraulic cylinder and the track.

► Tighten the tracks only up to the mandatory measuring distance.

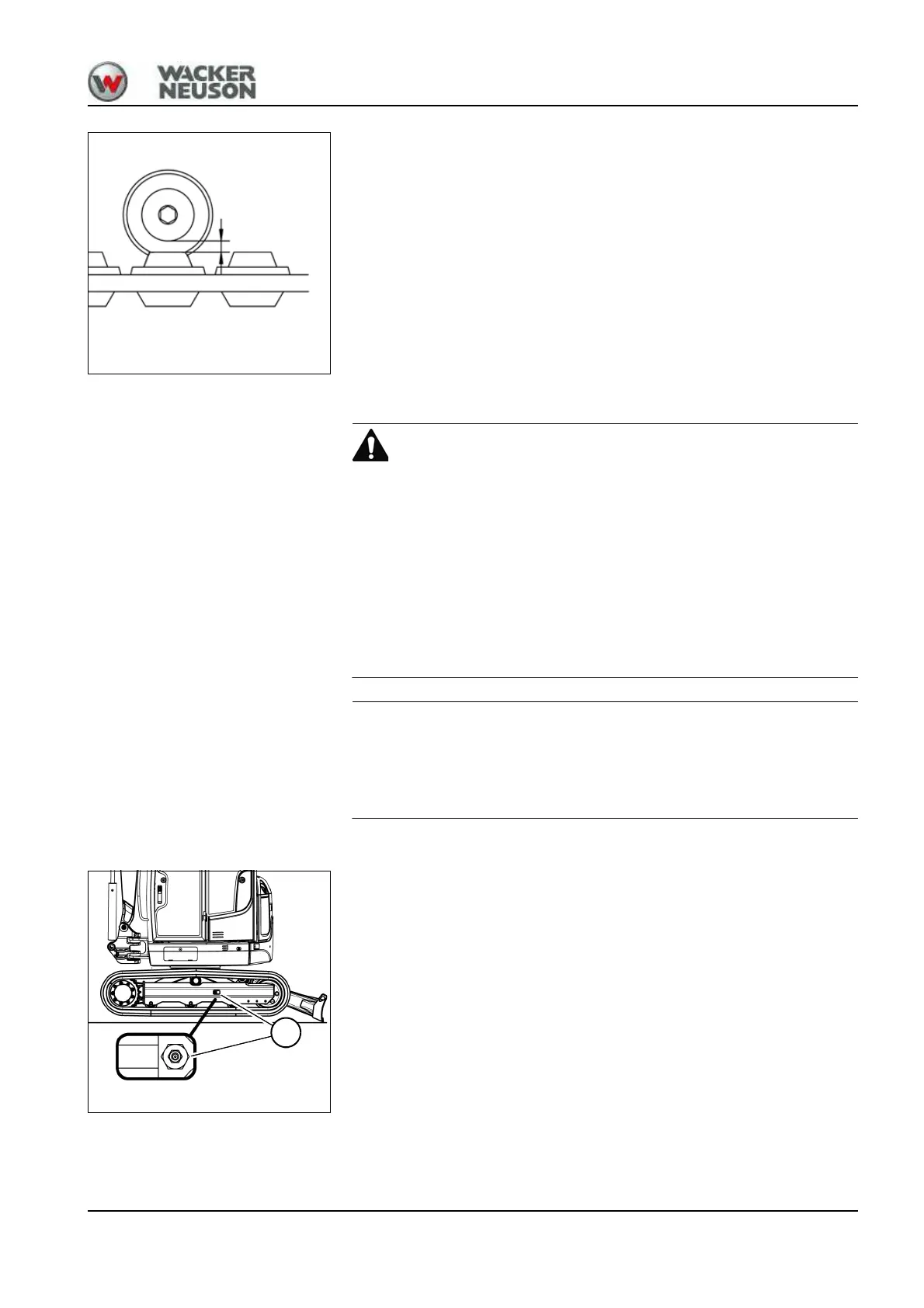

Tightening the tracks

1. Place the machine on firm, level and horizontal ground.

2. Raise the machine evenly and horizontally by means of the boom and

the stabilizer blade.

3. Stop the engine.

4. Operate the control lever repeatedly to release the pressure in the

hydraulic system.

5. Pump grease with a grease gun through lubricating valve A.

6. Lower the machine to the ground.

7. Check the tension is correct by:

- starting the engine,

- letting it run at idling speed without any load

- slowly moving the machine forward and reverse and switching it off

again.

8. Check the track tension again.

➥ If it is not correct:

Fig. 217

20 – 25 mm

(0.8 – 1 in)

Loading...

Loading...