03/2003

1-14

8850/ 510DP

Maintenance Procedures

Service Call Procedures

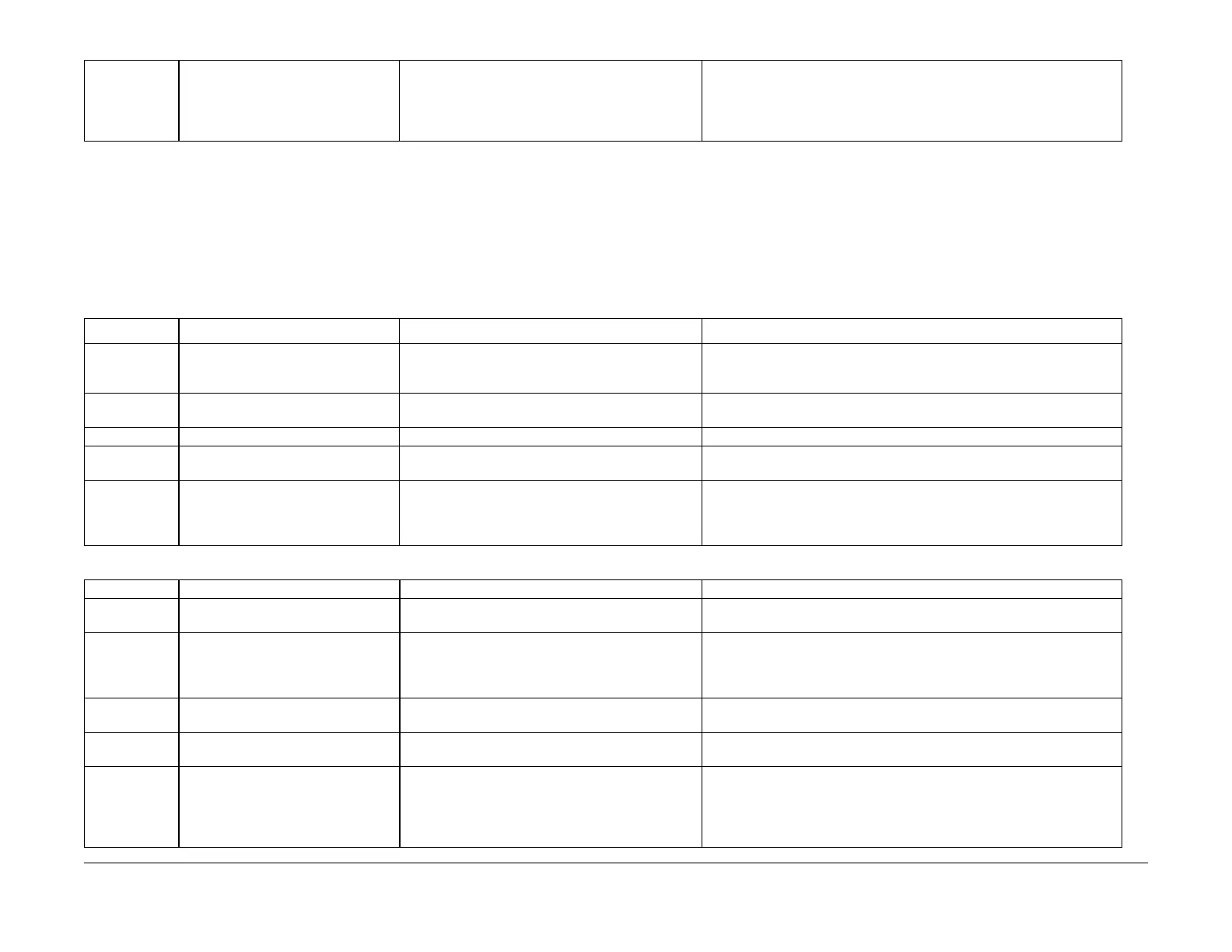

NOTE: 1. Ensure that the vacuum does not contact the edge of the cleaner blade that touches

the surface of the Drum.

NOTE: 2. Raise the Drum/Cleaning Module to dust the Drum and the cleaning blade with zinc

stearate to prevent the charge scorotron from being contaminated. Remove the Erase Bar to

prevent it from being contaminated. The zinc stearate may contaminate the charge scorotron

and Erase Bar and cause print quality defects.

NOTE: 3. Install the complete cleaning blade kit when installing a new Drum.

30K ft.

9Km

Clean the inner module components. If the customer is running a high percentage of vellum,

outgassing of the vellum contaminates the cleaner

auger and lower baffle surface resulting in poor clean-

ing and high dirt contamination.

plugged cleaner auger

Remove the Drum to enable access.

NOTE: Use caution not to touch or damage cleaning blade or seals.

Vacuum the Module and Auger and then clean all contaminated areas with

Film Remover.

Table 2 Drum/ Cleaner Module

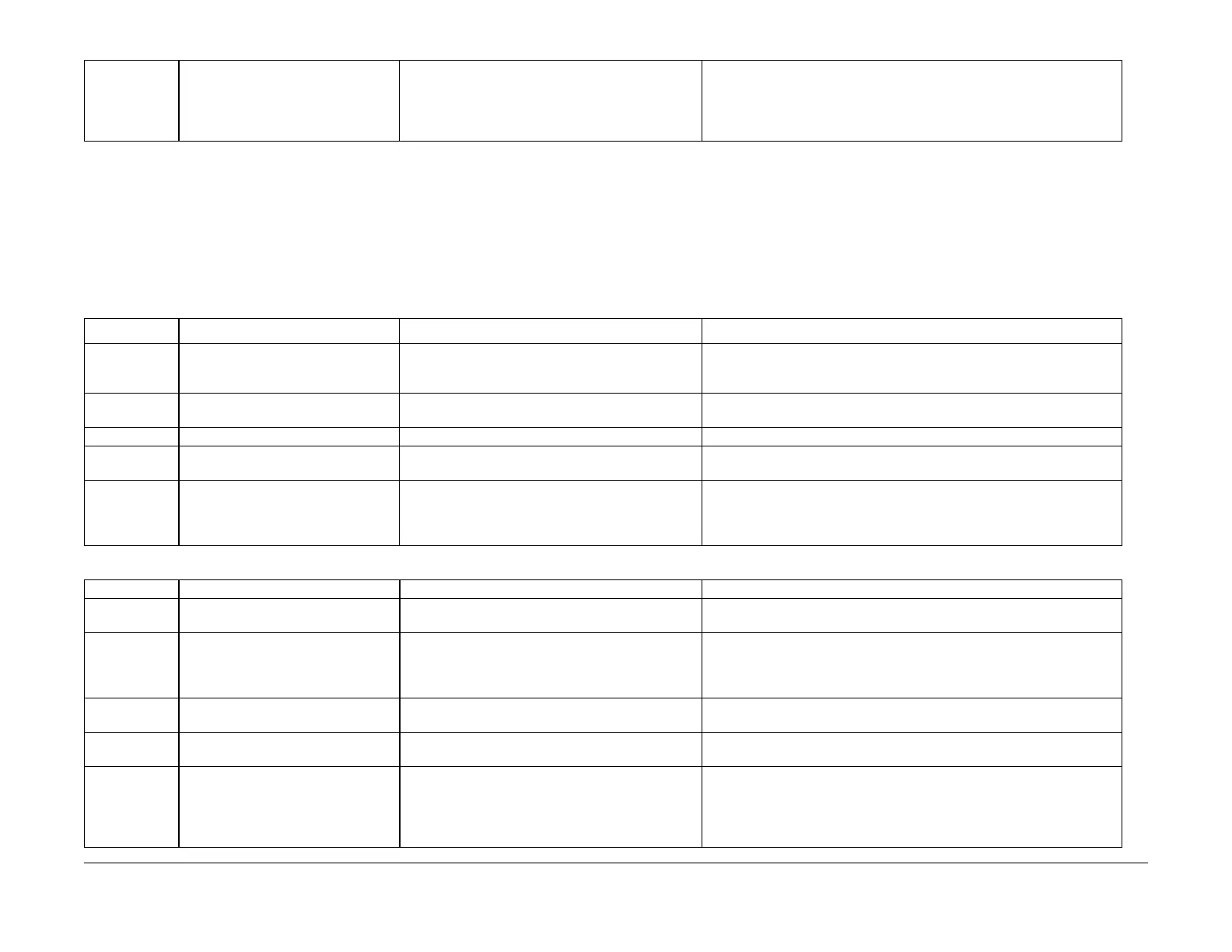

Table 3 Fuser Module

INTERVAL TASK REASON TASK ENABLER

Normal Call Replace the Fuser Heat Roll at failure. Smooth or worn Fuser Heat Roll loses ability to drive

media.

Check/Adjust the Fuser Temperature (ADJ 10.1).

Normal Call Check the Fuser Heat Roll for lack of

oil.

Too little oil can cause media handling and offsetting

print quality problems.

Check remaining fuser web life [1034] and adjust the Web Oiler rate [1032].

If the Fuser Heat Roll is dry, refer to BSD 10.2.

Normal Call Inspect/clean the thermistor pad Contamination can cause fuser heat problems. Clean the thermistor pad with a brush or dry lint free cloth.

Normal Call Clean the under side of the Fuser Mod-

ule and Sheet Feed Pinch Rolls.

Reduce the airborne contaminants. Wipe down with a lint free cloth and antistatic fluid.

Normal Call Check and clean or replace the Strip-

per Fingers.

Clean the Media Guides.

Bent Stripper Fingers may cause feed out jams and

Fuser Heat Roll damage.

Contaminated or damaged media guides can cause

print quality defects.

Replace the damaged or contaminated Stripper Fingers.

Table 4 Media Transport and Lower Sheet Feed Assembly

INTERVAL TASK REASON TASK ENABLER

Normal Call Clean the lower paper transports, turn-

around baffle, Sheet Feed Rolls.

Contaminates can cause the media to slip resulting in

print quality defects.

Clean the transport with antistatic fluid and a lint free cloth.

Clean the Sheet Feed Roller with Formula A.

Normal Call Vacuum clean the Bias Transfer Roll

(BTR).

Improve toner transfer to media. Rotate the Bias Transfer Roll in place as you vacuum. Clean loose toner/

debris with a vacuum. Just lightly touch the BTR as you move the vacuum

tool over the roll, do not press the vacuum tool against the roll. This could

tear and damage the BTR.

125K ft.

42Km

Replace the Bias Transfer Roll (BTR). Prevent print quality defects due to a worn roll. Remove the Bias Transfer Roll.

Normal Call Check / repair BTR spacing wheels as

required.

Contaminated, dirty or worn spacing wheels or Drum

ends cause print quality defects.

Clean the spacing wheels and the end surface of the Drum that the wheels

ride on.

Normal Call Check and clean or replace the Detack

Corotron Media Shields.

Contaminated or damaged Media Shields may cause

media jams.

Clean or replace the damaged or contaminated Media Shields. To clean the

area of the Media Shields, hold a vacuum tool close to the Shields and

brush any contaminates or toner loose for the vacuum to pick up.

Check the stainless steel shield on the rear of the Detack aluminum chan-

nel for a white powder. If a powder is present, replace the stainless shields.

Loading...

Loading...