60H5E11

Lower unit

LOWR

E

Installation depth A:

20.95 - 21.45 mm(0.8248 - 0.8445 in)

Installation depth B:

4.45 - 4.95 mm(0.1752 - 0.1949 in)

6-49

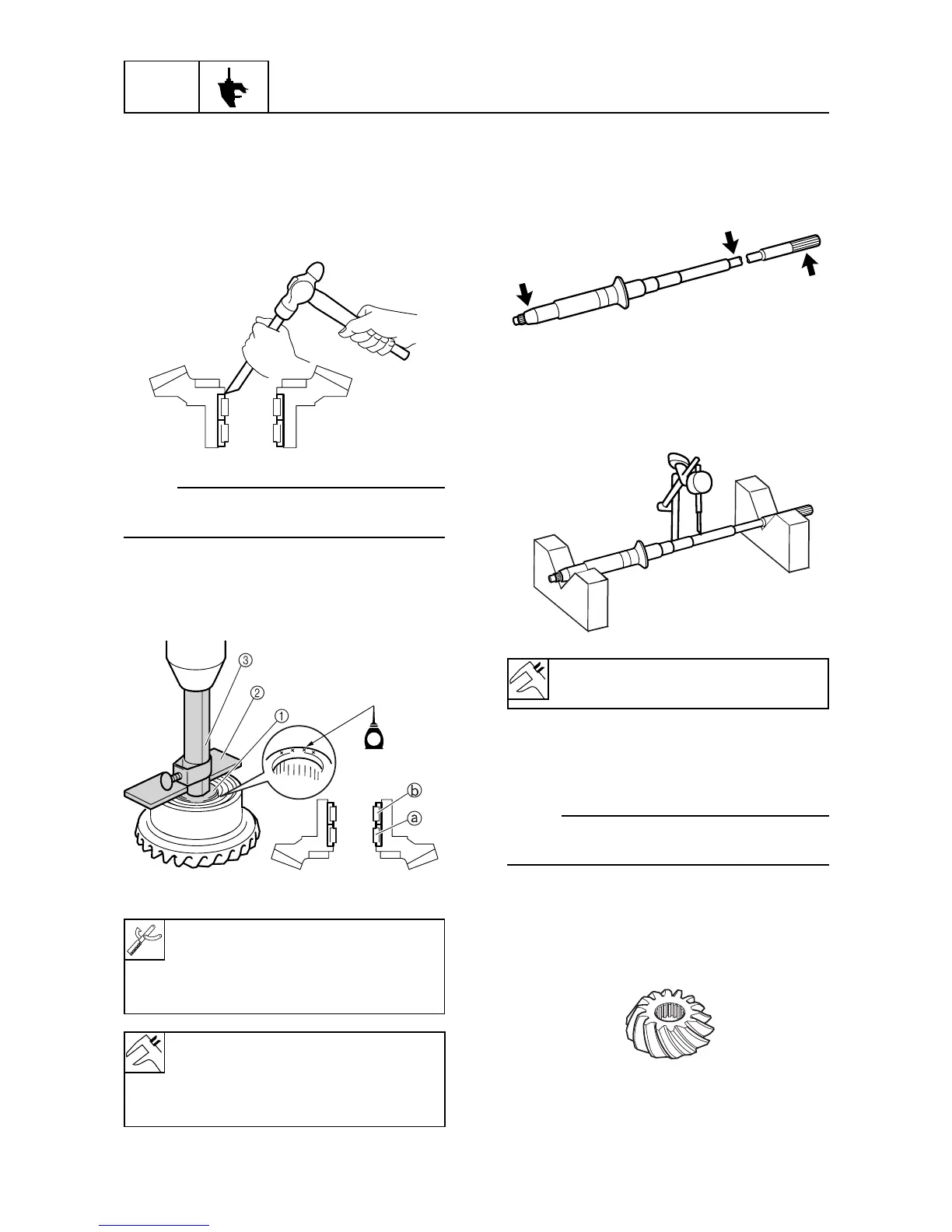

Checking the reverse gear

1. Check the teeth and dogs of the reverse

gear for cracks or wear. Also check the

bearing for run-out and roughness.

2. Remove the needle bearing.

60h60380

NOTE:

When the needle bearing is removed, always

replace them with a new one.

Assembling the reverse gear

1. Install the needle bearing.

60h60390

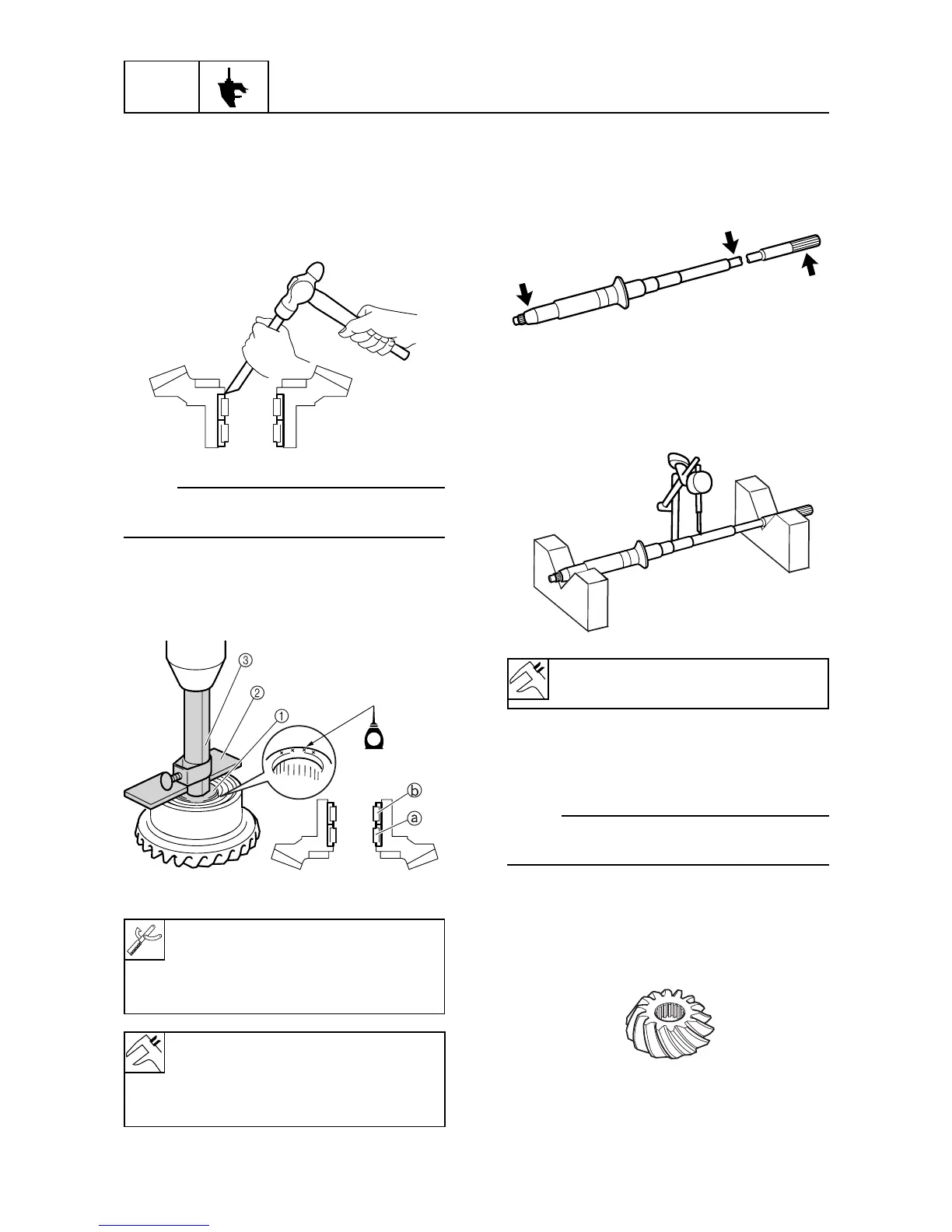

Checking the drive shaft

1. Check the drive shaft for bends or wear.

Replace if necessary.

60h60410

2. Measure the drive shaft run-out.

60h60415

3. Check the thrust bearing for run-out or

roughness. Replace if necessary.

NOTE:

Shimming is required when the thrust bearing

is replaced.

Checking the pinion gear

1. Check the pinion gear teeth for cracks or

wear.

60h60420

Run-out limit: 0.1 mm (0.0039 in)

Needle bearing attachment 1:

90890-06612

Bearing depth plate 2: 90890-06603

Driver rod SS 3: 90890-06604

Loading...

Loading...