60H5E11

4

4-12

Carburetor

Disassembling the carburetor

NOTE:

• Write down how many turns you have actu-

ally turned out the pilot screw.

• Disassembled jets and other components

shall be sorted out and kept in order, so that

they are re-assembled to the original posi-

tion without fail.

• Do not bend the plate of the float.

Checking the carburetor

1. Clean the fuel passage, air passage and

the carburetor body, and blow off any clog-

ging with compressed air.

Wear appropriate protective eye gear dur-

ing the cleaning process to prevent any eye

injury by the blown-off fractions or liquid.

Do not use steel wire and the like for clean-

ing the carburetor. Do not try to disas-

semble the main nozzle if it does not come

out easily. Excessive force may impair the

performance in the serious way.

NOTE:

Clean the needle valve, main jet, and pilot jet

afrer removal.

2. Check the carburetor body for cracks or

damage. Replace it if necessary.

3. Check the pilot screws and needle valves

for bending or stepped wear. Replace them

if necessary.

60H40150

4. Check the main jet, pilot jet, main air jet,

pilot air jet, and main nozzle for clogging

and contamination. Clean or replace them

whenever appropriate.

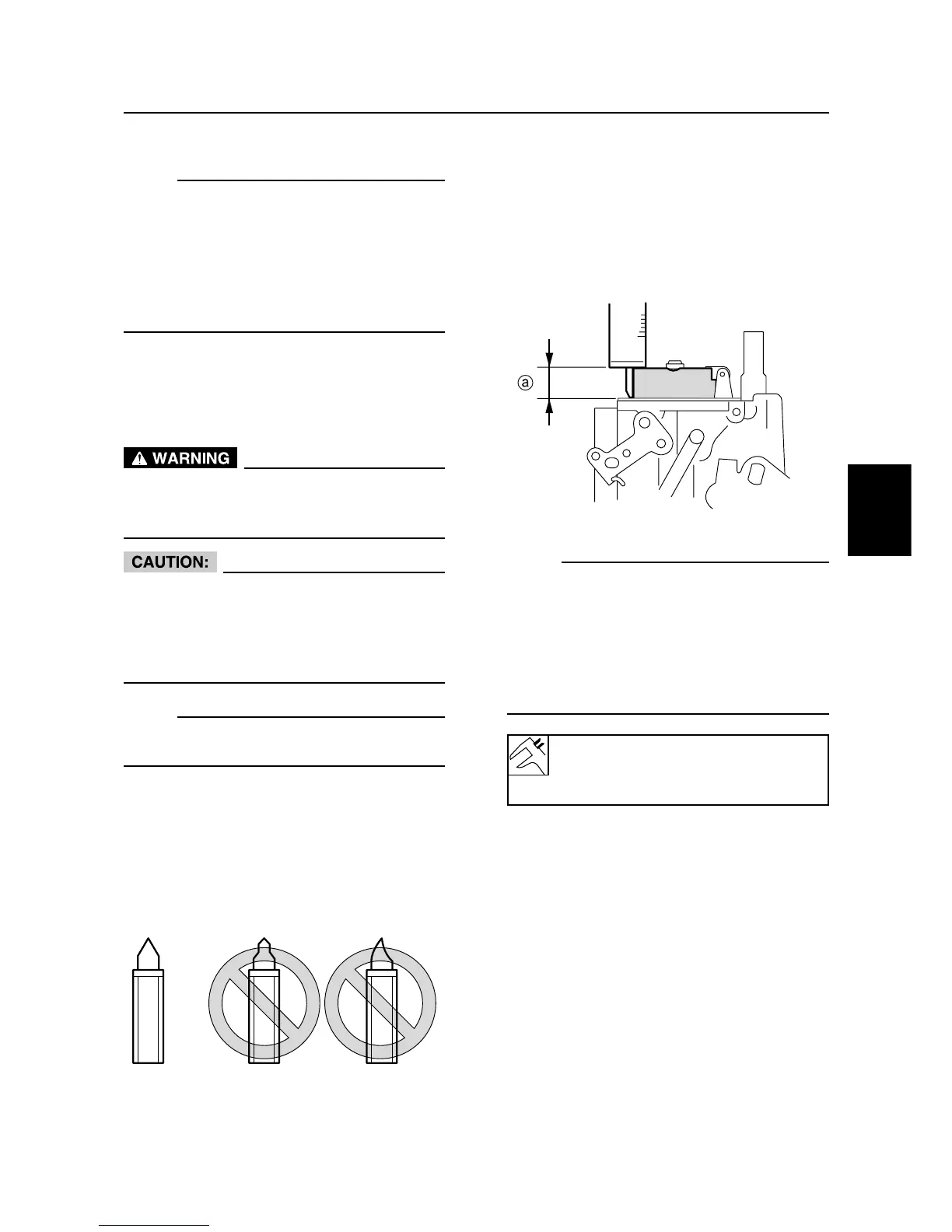

5. Check the float for damage, and make sure

it is at the appropriate height A. Replace

the float or needle or both if necessary.

60H40160

NOTE:

• Measure the float's height at the end oppo-

site to the needle valve.

• The float should be resting on the needle

valve, but not compressing it.

• Measure the distance A i.e. from carburetor

mating face to the float bottom. Invert the

carburetor for the measurement.

Vertical position of the float A

(with gasket):

15.5 - 16.5mm (0.61-0.65 in)

Loading...

Loading...