CONNECTING RODS AND PISTONS

Connecting rod

bolt

(1st)

20 Nm (2.0 m-kgf, 14

ft

·lbf)

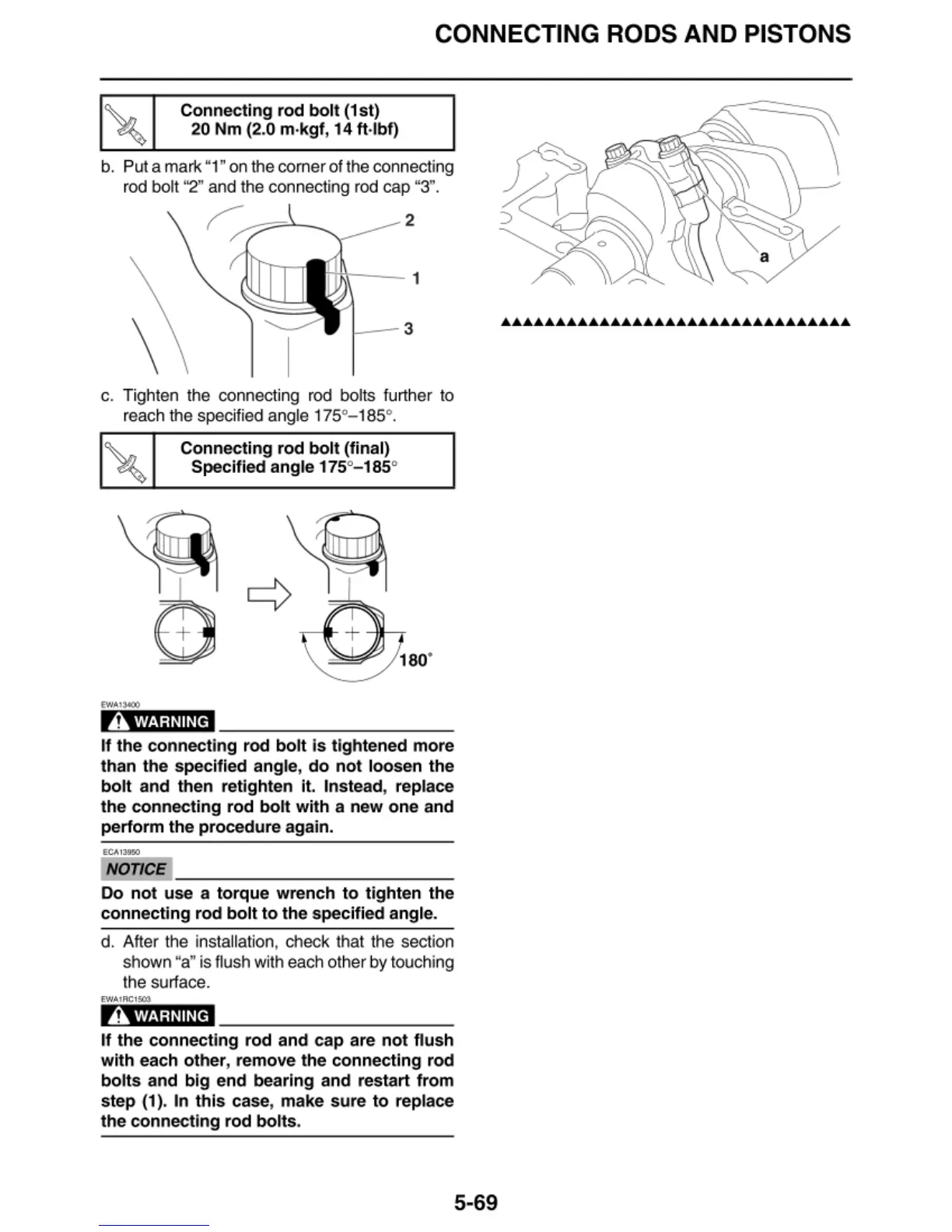

b. Put a mark "1" on the corner of the connecti

ng

rod bolt "2" and the connecting rod cap "3".

----

2

--

1

\

1

--

3

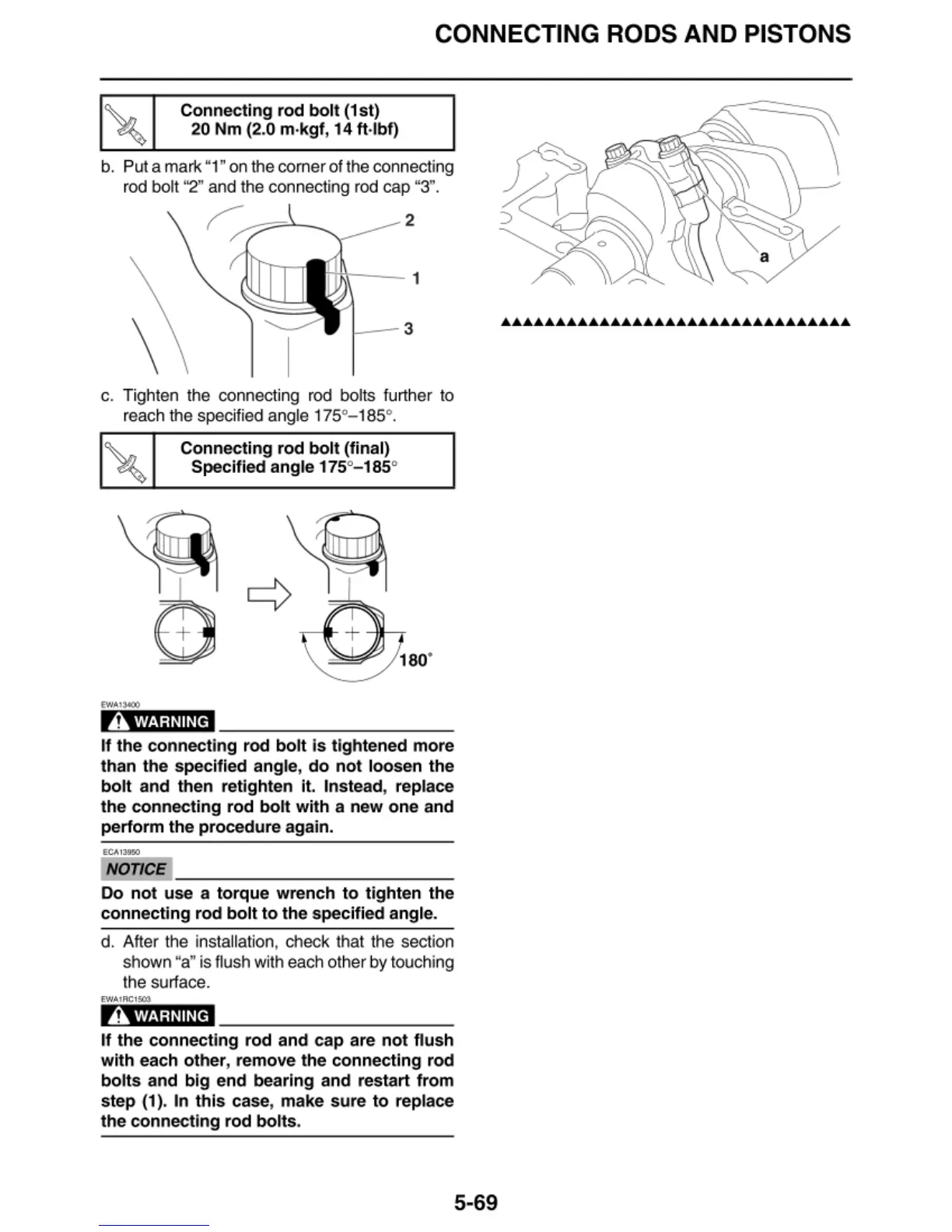

c. Tighten the connecting rod bolts further to

reach t

he

specified angle 175°

-185

°.

EWA

l

$400

Connecting rod

bolt

(final)

Specified angle

175°

-185

°

I

ID

.---l

l-

+

AwARNING

If

the

connecting rod

bolt

Is

tightened more

than

the

specified angle,

do

not

loosen the

bolt

and then retighten it. Instead, replace

the connecting rod

bolt

with a

new

one and

perform the procedure again.

ECAIW..0

NOTICE~~~~~~~~~~~~

Do

not

use a torque wrench

to

tighten the

connecting rod

bolt

to

the specified angle.

d. After the insta

ll

a

ti

on, check that the section

shown "a" is flush with each other by touching

the

su

rf

ace.

EWA

IAC1

5'JG

AwARNING

If the connecting rod and cap

are

not

flush

with each

other

, remove the connecting rod

bolts

and

big

end bearing and restart from

step

(1

). In

this

case, make sure to replace

the connecting rod

bolts

.

5-69

Loading...

Loading...