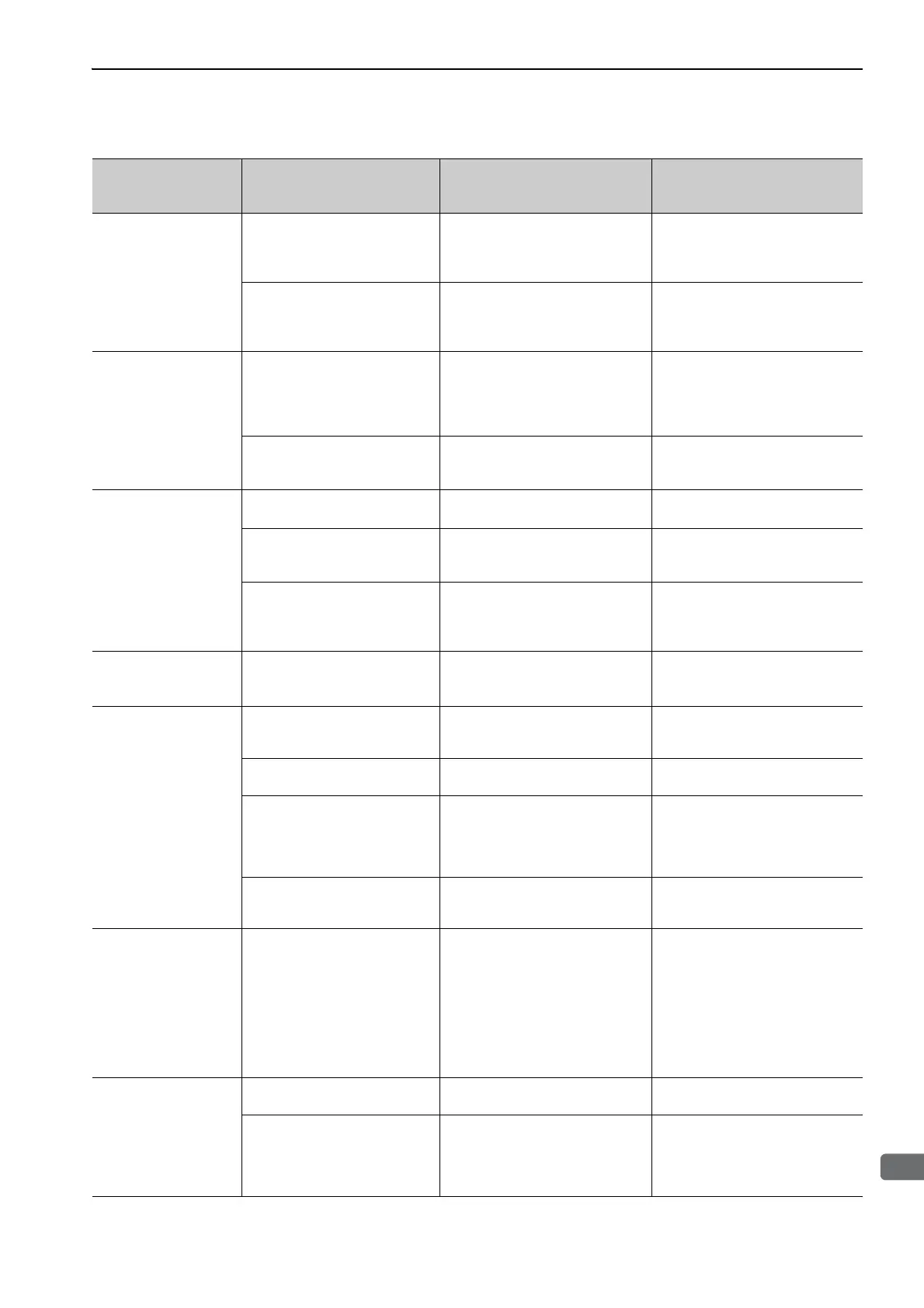

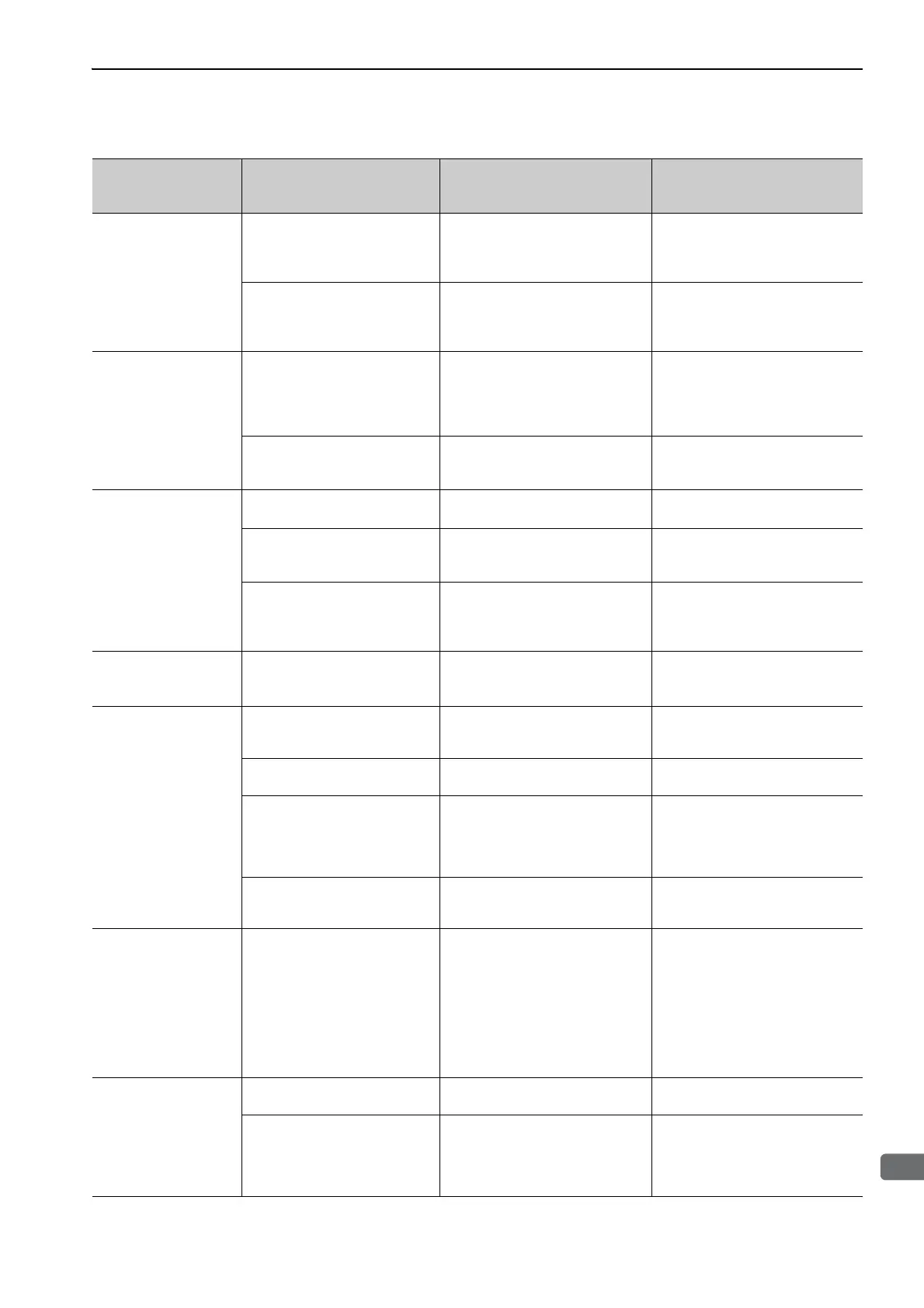

10.2 Alarm Displays

10-9

10

Maintenance, Inspections, and Troubleshooting

A.520:

Vibration Alarm

Abnormal vibration was detected

at the motor speed.

Check for abnormal noise from the

servomotor, and check the speed

and torque waveforms during oper-

ation.

Reduce the motor speed or reduce

the speed loop gain (PnAC2).

The moment of inertia ratio

(Pn103) value is greater than the

actual value or is greatly

changed.

Check the moment of inertia ratio.

Set the moment of inertia ratio

(Pn103) to an appropriate value.

A.521:

Autotuning Alarm

(Vibration was

detected while

executing the one-

parameter tuning,

EasyFFT, or tuning-

less function.)

The servomotor vibrated consid-

erably while performing tuning-

less function.

Check the motor speed waveform.

Reduce the load so that the moment

of inertia ratio falls within the

allowable value, or raise the load

level using the tuning-less levels

setting or reduce the rigidity level.

The servomotor vibrated consid-

erably during one-parameter tun-

ing or EasyFFT.

Check the motor speed waveform.

Check the operation procedure of

corresponding function and take a

corrective action.

A.710:

A.720:

Overload

A.710: High Load

A.720: Low Load

Incorrect wiring or contact fault

of servomotor and encoder.

Check the wiring.

Confirm that the servomotor and

encoder are correctly wired.

Operation beyond the overload

protection characteristics.

Check the servomotor overload

characteristics and executed run

command.

Reconsider the load conditions and

operating conditions. Or, increase

the motor capacity.

Excessive load was applied

during operation because the ser-

vomotor was not driven due to

mechanical problems.

Check the executed operation refer-

ence and motor speed.

Remove the mechanical problems.

A.7A3:

Control Board

Overheat

The surrounding air temperature

of the SERVOPACK is too high.

Measure the surrounding air tem-

perature of the SERVOPACK.

Improve the installation conditions

of the SERVOPACK to reduce the

surrounding air temperature.

A.810:

Encoder Backup Error

(Only when an

absolute encoder is

connected.)

(Detected on the

encoder side.)

Alarm occurred when the power

to the absolute encoder was ini-

tially turned ON.

Check to see if the power was

turned ON initially.

Set up the encoder.

The encoder cable disconnected,

and connected again.

Check to see if the power was

turned ON initially.

Confirm the connection and set up

the encoder.

The power from both the control

power supply (+5 V) from the

SERVOPACK and the battery

power supply is not being sup-

plied.

Check the encoder connector bat-

tery or the connector contact status.

Replace the battery or take similar

measures to supply power to the

encoder, and set up the encoder.

An absolute encoder fault

occurred.

−

If the alarm cannot be reset by set-

ting up the encoder again, replace

the servomotor.

A.820:

Encoder Checksum

Error

(Detected on the

encoder side.)

An encoder fault occurred. −

• Absolute encoder

Set up the encoder again using

Fn008. If the alarm still occurs,

the servomotor may be faulty.

Replace the servomotor.

• One-turn absolute encoder or

incremental encoder

The servomotor may be faulty.

Replace the servomotor.

A.830:

Absolute Encoder

Battery Error

(The absolute encoder

battery voltage is

lower than the

specified value.)

The battery connection is incor-

rect.

Check the battery connection. Reconnect the battery.

The battery voltage is lower than

the specified value 2.7 V.

Measure the battery voltage. Replace the battery.

(cont’d)

Alarm Number:

Alarm Name

(Alarm Description)

Cause Investigative Actions Corrective Actions

Loading...

Loading...