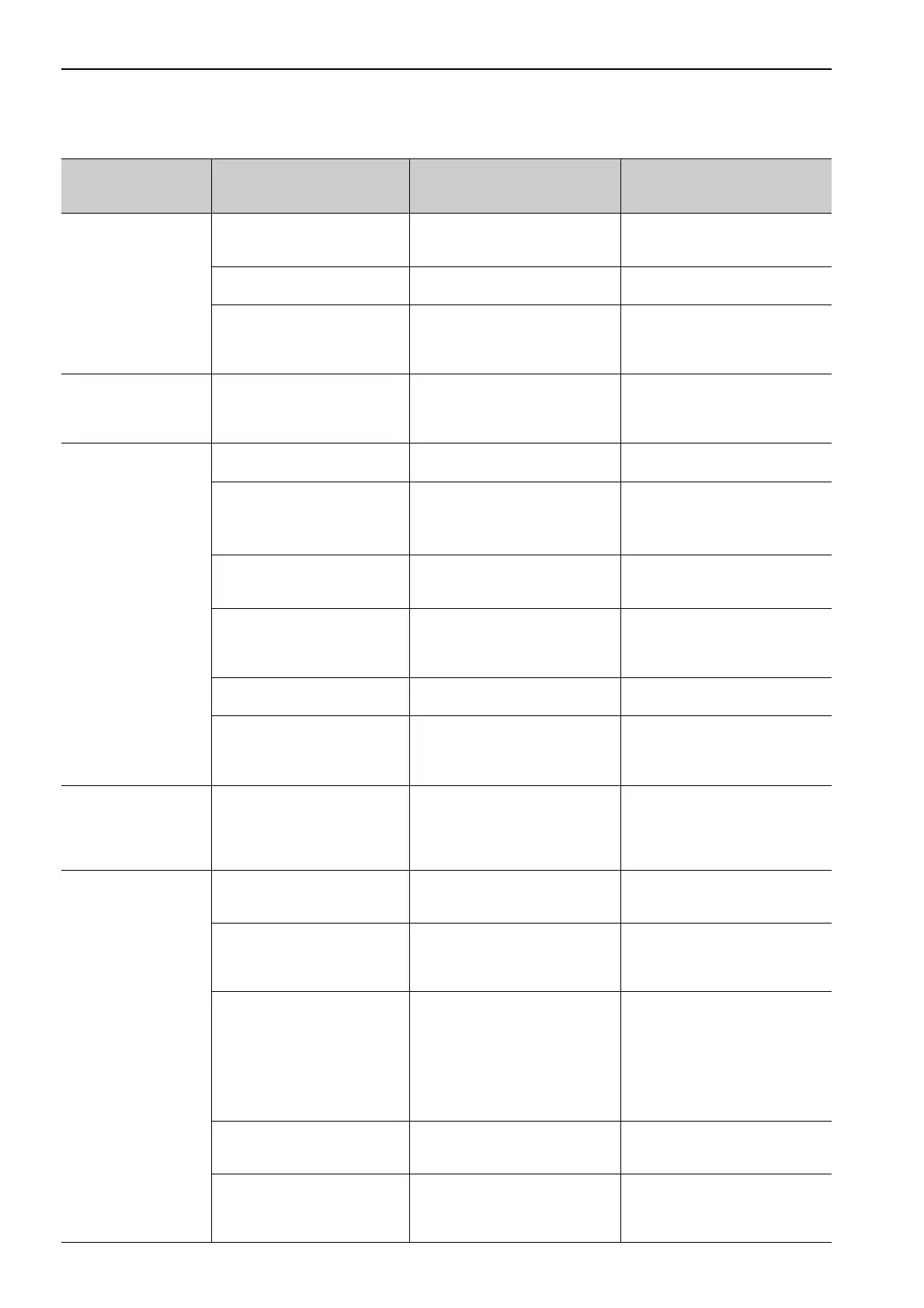

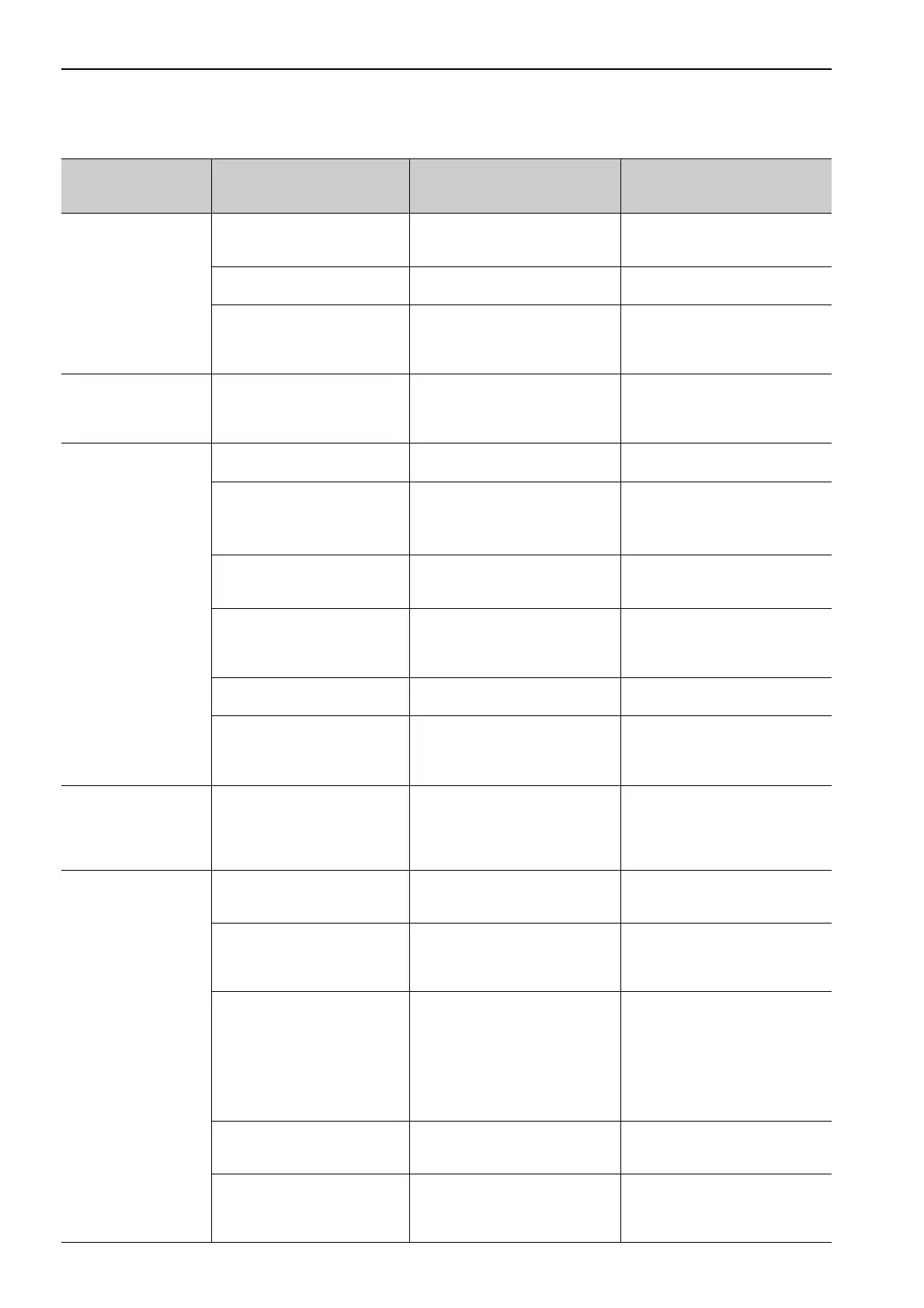

10 Maintenance, Inspections, and Troubleshooting

10.2.2 Troubleshooting of Alarms

10-12

A.C92:

Encoder

Communications

Timer Error

Noise interference occurred on

the I/O signal line from the

encoder.

−

Take countermeasures against noise

for the encoder wiring.

Excessive vibration and shocks

were applied to the encoder.

Check the operating environment.

Reduce the machine vibration or

correctly install the servomotor.

An encoder fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the servomotor

may be faulty. Replace the servo-

motor.

A.CA0:

Encoder Parameter

Error

An encoder fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the servomotor

may be faulty. Replace the servo-

motor.

A.Cb0:

Encoder Echoback

Error

The wiring and contact for

encoder cable are incorrect.

Check the wiring. Correct the wiring.

Noise interference occurred due

to incorrect cable specifications

of encoder cable.

−

Use tinned annealed copper

shielded twisted-pair or screened

unshielded twisted-pair cable with a

core of at least 0.12 mm

2

.

Noise interference occurred

because the wiring distance for

the encoder cable is too long.

−

The wiring distance must be 10 m

max.

The FG potential varies because

of influence from machines on

the servomotor side, such as the

welder.

Check the cable layout for encoder

cable.

Properly ground the machines to

separate from encoder FG.

Excessive vibration and shocks

were applied to the encoder.

Check the operating environment.

Reduce the machine vibration or

correctly install the servomotor.

An encoder fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the servomotor

may be faulty. Replace the servo-

motor.

A.CC0:

Multiturn Limit

Disagreement

The multiturn limit value of the

encoder is different from that of

the SERVOPACK. Or, the multi-

turn limit value of the SERVO-

PACK has been changed.

Check the value of the PnA48 of the

SERVOPACK.

Execute Fn013 at the occurrence of

alarm.

A.d00:

Position Error

Overflow

(Position error exceeded

the value set in the

excessive position error

alarm level (Pn520).)

The servomotor U, V, and W wir-

ings is faulty.

Check the servomotor main circuit

cable connection.

Confirm that there is no contact

fault in the motor wiring or encoder

wiring.

The position reference speed is

too high.

Reduce the reference speed, and

operate the SERVOPACK.

Reduce the position reference speed

or acceleration of position refer-

ence. Or, reconsider the electronic

gear ratio.

The acceleration of the position

reference is too high.

Reduce the reference acceleration,

and operate the SERVOPACK.

Reduce the reference acceleration

of the position reference using a

MECHATROLINK command, or

smooth the acceleration of the posi-

tion reference by selecting the posi-

tion reference filter (ACCFIL)

using a MECHATROLINK com-

mand.

Setting of the excessive position

error alarm level (Pn520) is low

against the operating condition.

Check the alarm level (Pn520) to

see if it is set to an appropriate

value.

Set the Pn520 to proper value.

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

(cont’d)

Alarm Number:

Alarm Name

(Alarm Description)

Cause Investigative Actions Corrective Actions

Loading...

Loading...