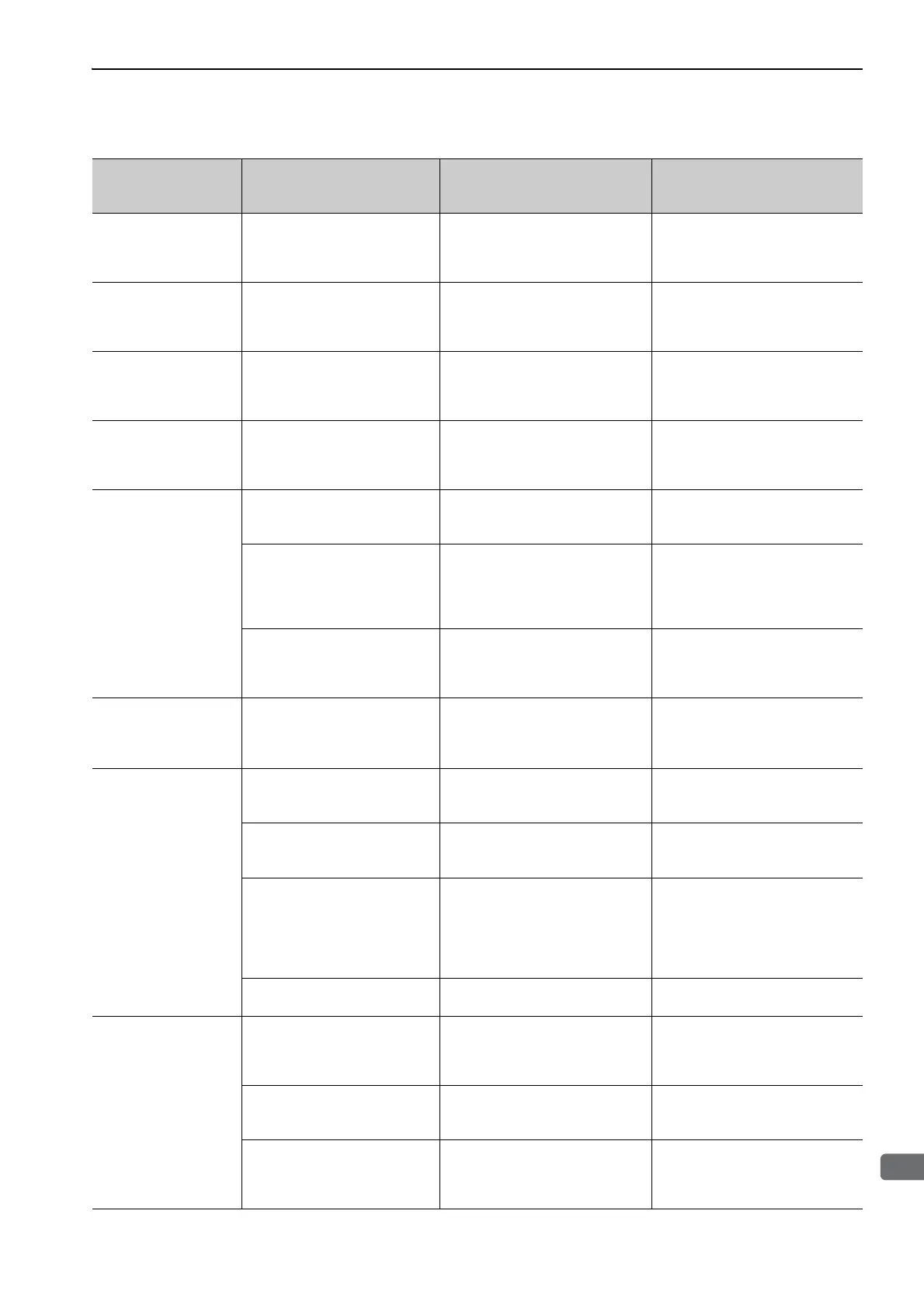

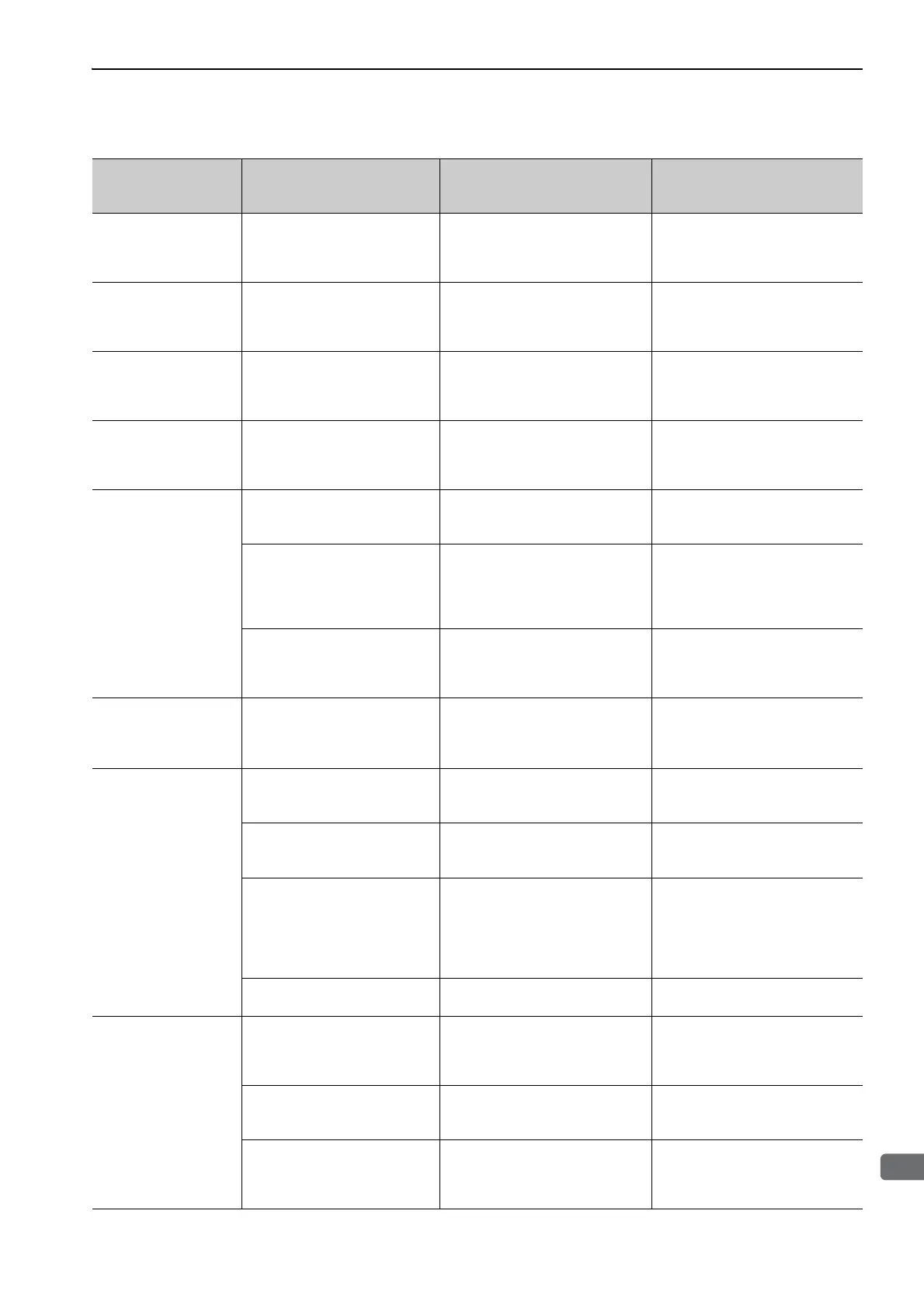

10.2 Alarm Displays

10-11

10

Maintenance, Inspections, and Troubleshooting

A.bF1:

System Alarm 1

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

A.bF2:

System Alarm 2

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

A.bF3

:

System Alarm 3

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

A.bF4:

System Alarm 4

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

A.C10:

Servo Overrun

Detected

(Detected when the

servomotor power is

ON.)

The order of phases U, V, and W

in the servomotor wiring is incor-

rect.

Check the motor wiring.

Confirm that the servomotor is cor-

rectly wired.

An encoder fault occurred. −

If the alarm still occurs after restart-

ing the SERVOPACK, even though

the servomotor is correctly wired,

the servomotor may be faulty.

Replace the servomotor.

A SERVOPACK fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the SERVO-

PACK may be faulty. Replace the

SERVOPACK.

A.C80:

Absolute Encoder

Clear Error and Multi-

turn Limit Setting Error

An encoder fault occurred. −

Restart the SERVOPACK. If the

alarm still occurs, the servomotor

may be faulty. Replace the servo-

motor.

A.C90:

Encoder

Communications Error

Contact fault of connector or

incorrect wiring for encoder

cable.

Check the connector contact status

for encoder cable.

Re-insert the connectors and con-

firm that the encoder is correctly

wired.

Cable disconnection for encoder

cable or short-circuit.

Or, incorrect cable impedance.

Check the encoder cable.

Use the cables with the specified

rating.

Corrosion caused by improper

temperature, humidity, or gas,

short-circuit caused by intrusion

of water drops or cutting oil, or

connector contact fault caused by

vibration.

Check the operating environment.

Improve the operating environmen-

tal conditions, and replace the cable.

If the alarm still occurs, replace the

SERVOPACK.

Malfunction caused by noise

interference.

−

Correct the wiring around the

encoder (e.g., grounding).

A.C91:

Encoder

Communications

Position Data Error

Noise interference occurred on

the I/O signal line because the

encoder cable is bent and the

sheath is damaged.

Check the encoder cable and con-

nector.

Confirm that there is no problem

with the cable layout.

The encoder cable is bundled

with a high-current line or near a

high-current line.

Check the cable layout for encoder

cable.

Confirm that there is no surge volt-

age on the cables.

The FG potential varies because

of influence from machines on

the servomotor side, such as the

welder.

Check the cable layout for encoder

cable.

Properly ground the machines to

separate from the encoder FG.

(cont’d)

Alarm Number:

Alarm Name

(Alarm Description)

Cause Investigative Actions Corrective Actions

Loading...

Loading...