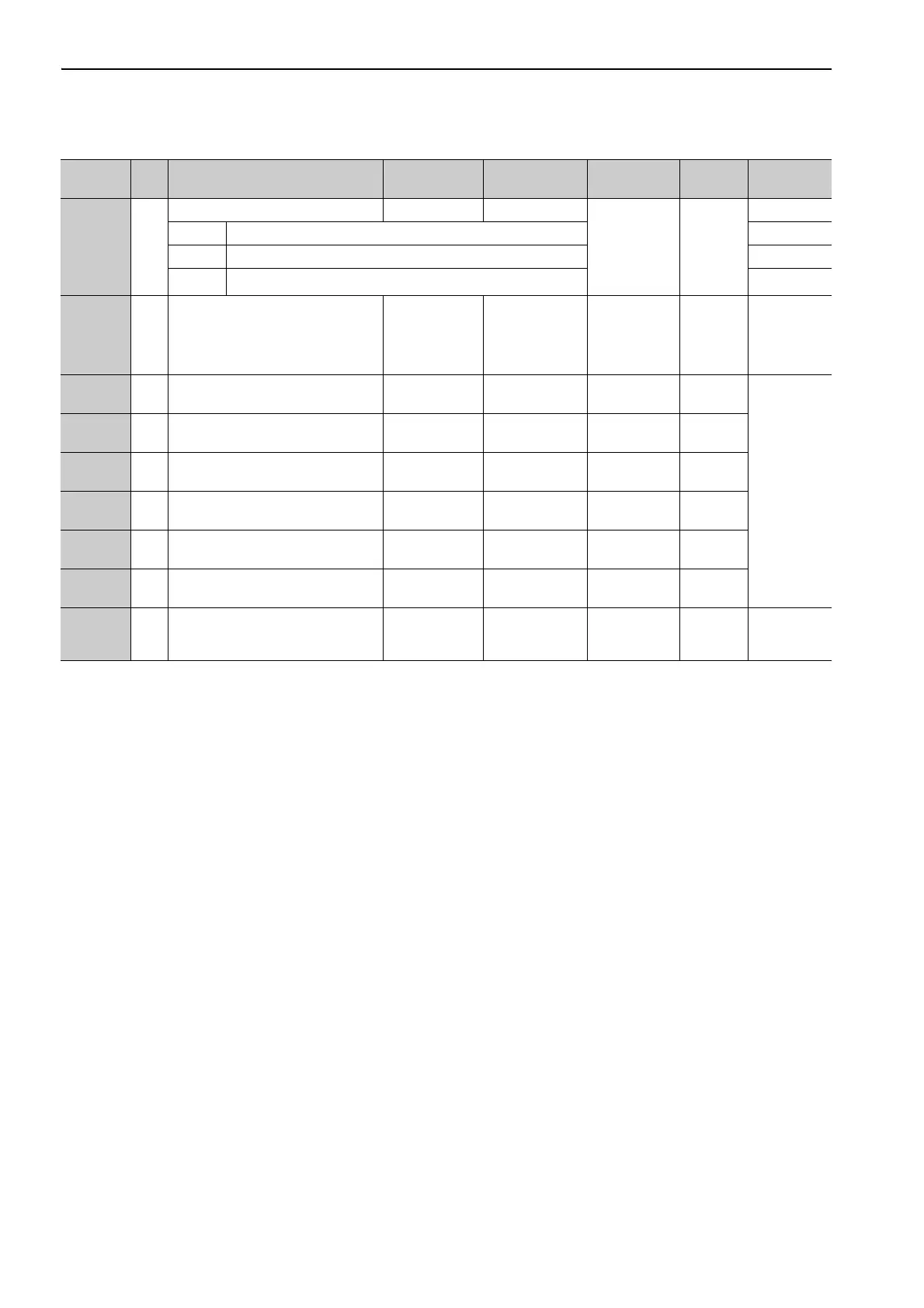

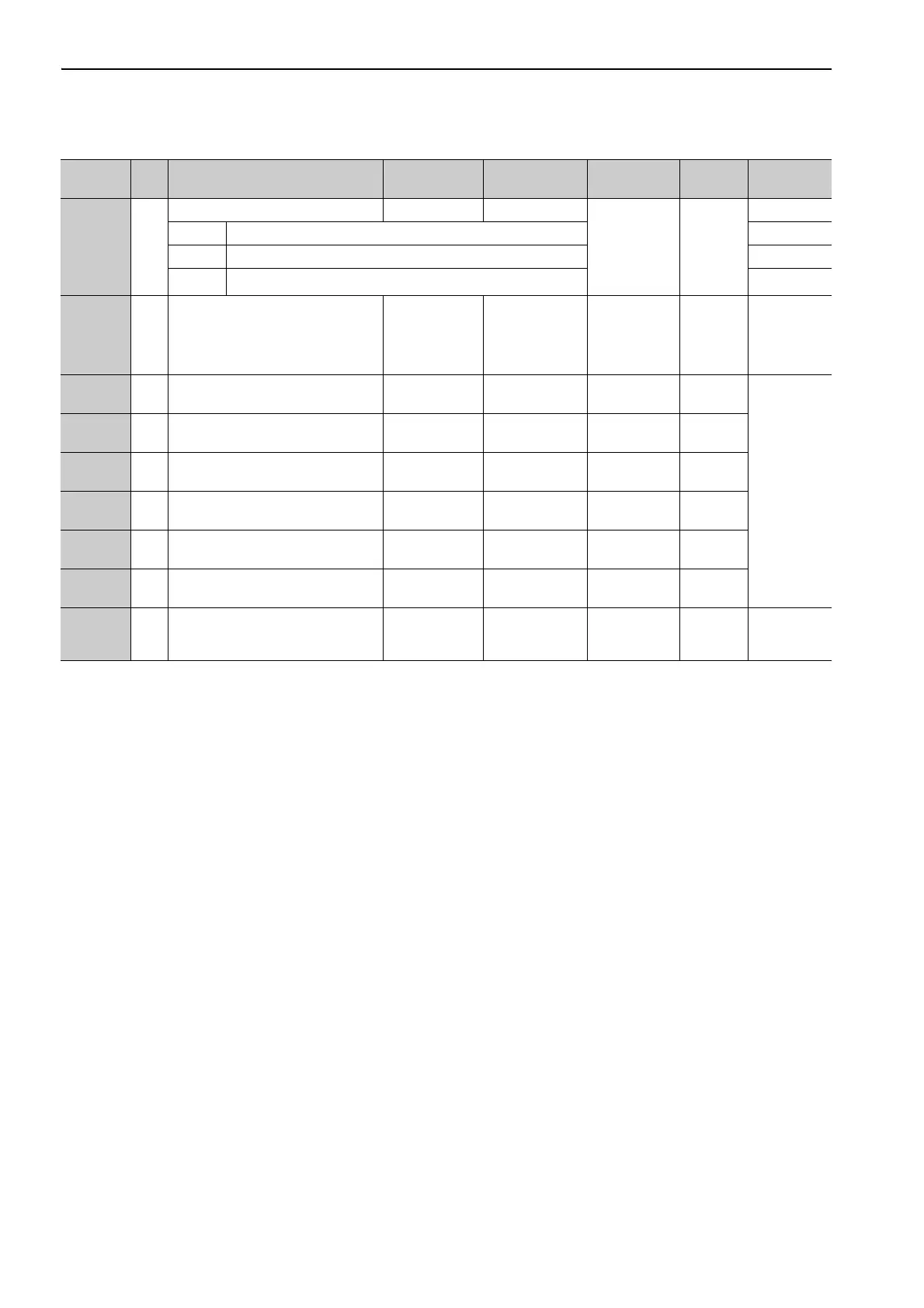

11 Appendix

11.2.2 MECHATROLINK-III Common Parameters

11-22

47

PnA8E

4

Torque Unit 1 and 2 –

1

After

restart

0000H Not supported

0001H Percentage (%) of rated torque

0002H

Max. torque/40000000H

*4

48

PnA90

4

Torque Base Unit

*4

(Set the value of “n” used as the

exponent in 10

n

when calculating

the Torque Unit (47).)

–5 to 0 – 0

After

restart

61

PnAC2

4 Speed Loop Gain

1000 to

2000000

0.001 Hz

[0.1 Hz]

40000

Immedi-

ately

Adjustment

Related

Parameters

62

PnAC4

4 Speed Loop Integral Time Constant 150 to 512000

μs

[0.01 ms]

20000

Immedi-

ately

63

PnAC6

4 Position Loop Gain

1000 to

2000000

0.001/s

[0.1/s]

40000

Immedi-

ately

64

PnAC8

4 Feedforward Compensation 0 to 100 1% 0

Immedi-

ately

65

PnACA

4

Position Loop Integral Time Con-

stant

0 to 5000000

μs

[0.1 ms]

0

Immedi-

ately

66

PnACC

4 Positioning Completed Width

0 to

1073741824

1 reference unit 7

Immedi-

ately

67

PnACE

4 NEAR Signal Width

1 to

1073741824

1 reference unit 1073741824

Immedi-

ately

Adjustment

Related

Parameters

∗4. When 0002H is selected for the Torque Unit (parameter 47), set the Torque Base Unit (parameter 48) to 0.

∗5. Change the setting when the reference is stopped (DEN is set to 1), because the change will affect the output during

operation.

Note: When using parameters that are enabled after restarting the SERVOPACK, a CONFIG command must be input or

the power must be turned OFF and then ON again.

(cont’d)

Parameter

No.

Size Name Setting Range

Units

[Resolution]

Factory

Setting

When

Enabled

Classifica-

tion

Loading...

Loading...