12.7 L: Protection Functions

334 YASKAWA SIEPYEULA5001C LA500 Technical Manual

◆ L6: Torque Detection

■ Overview

The overtorque/undertorque detection function prevents damage to machinery and loads.

Overtorque is when there is too much load on the machine. If the motor current or output torque is at the

overtorque detection level for the overtorque detection time, the drive will output an alarm and turn off the output.

Undertorque is when a load suddenly decreases. When the motor current or output torque is at the undertorque

detection level for the undertorque detection time, the drive will output an alarm and turn off the output.

You can use the undertorque detection function to detect these conditions, for example:

• Machine belt cuts

• Unusual operation of the electromagnetic contactor on the drive output side

• Clogged output side air filters in fans and blowers

• Damage to blade tips and broken string

Note:

If there is oC [Overcurrent] or oL1 [Motor Overload], the drive can stop during overtorque conditions. Use torque detection to identify

overload conditions before the drive detects oC or oL1 and stops. Use this function to detect issues that occur in the application.

■ Parameter Settings

You can individually set the two overtorque/undertorque detection functions with the drive. Use the information in

Table 12.10 to set the parameters.

Table 12.10 Overtorque/Undertorque Detection Parameters

Configuration Parameter Overtorque/Undertorque Detection 1 Overtorque/Undertorque Detection 2

MFDO Function Select

• Terminal MA-MC

• Terminal P1-C1

• Terminal P2-C2

H2-01, H2-02, and H2-03 = B

N.O.: Activated when detected

H2-01, H2-02, and H2-03 = 18

N.O.: Activated when detected

H2-01, H2-02, and H2-03 = 17

N.C.: Disactivated when detected

H2-01, H2-02, and H2-03 = 19

N.C.: Disactivated when detected

Detection conditions and selection of operation after

detection

L6-01 L6-04

Detection Level L6-02 L6-05

Detection Time L6-03 L6-06

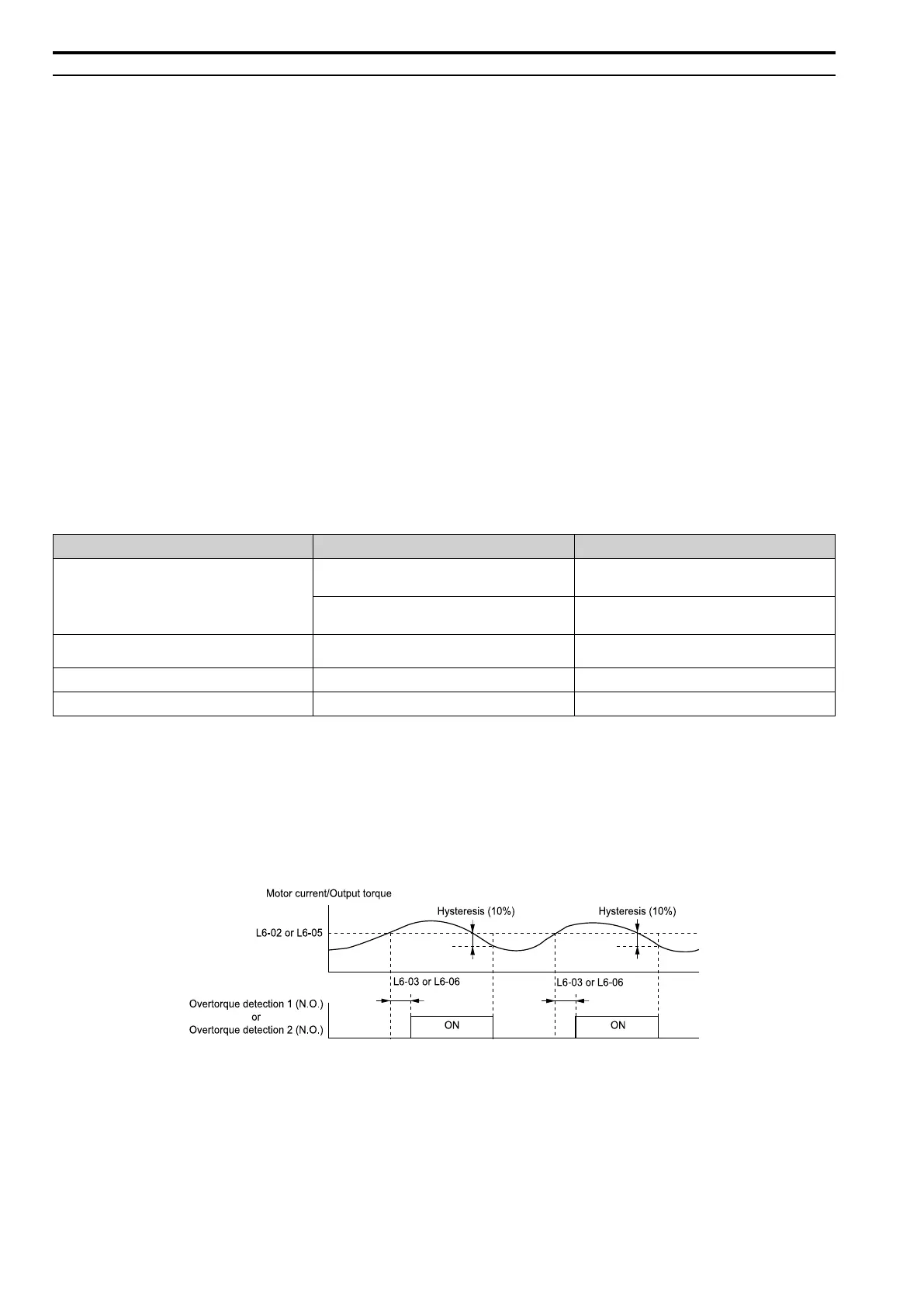

■ Overtorque Detection Time Chart

When you use Overtorque/Undertorque Detection 1, the drive detects overtorque if the motor current or motor

torque is at the detection level set in L6-02 [Torque Detection Level 1] for the time set in L6-03 [Torque Detection

Time 1]. Parameter L6-01 [Torque Detection Selection 1] sets the operation after detection.

When you use Overtorque/Undertorque Detection 2, set L6-04 [Torque Detection Selection 2], L6-05 [Torque

Detection Level 2], and L6-06 [Torque Detection Time 2].

Set the terminal that outputs the alarm in H2-01 to H2-03 [MFDO Function Select].

Figure 12.31 Overtorque Detection Time Chart

Note:

The drive applies a hysteresis of approximately 10% of the drive rated output current or the motor rated torque to the overtorque/

undertorque detection function.

Loading...

Loading...