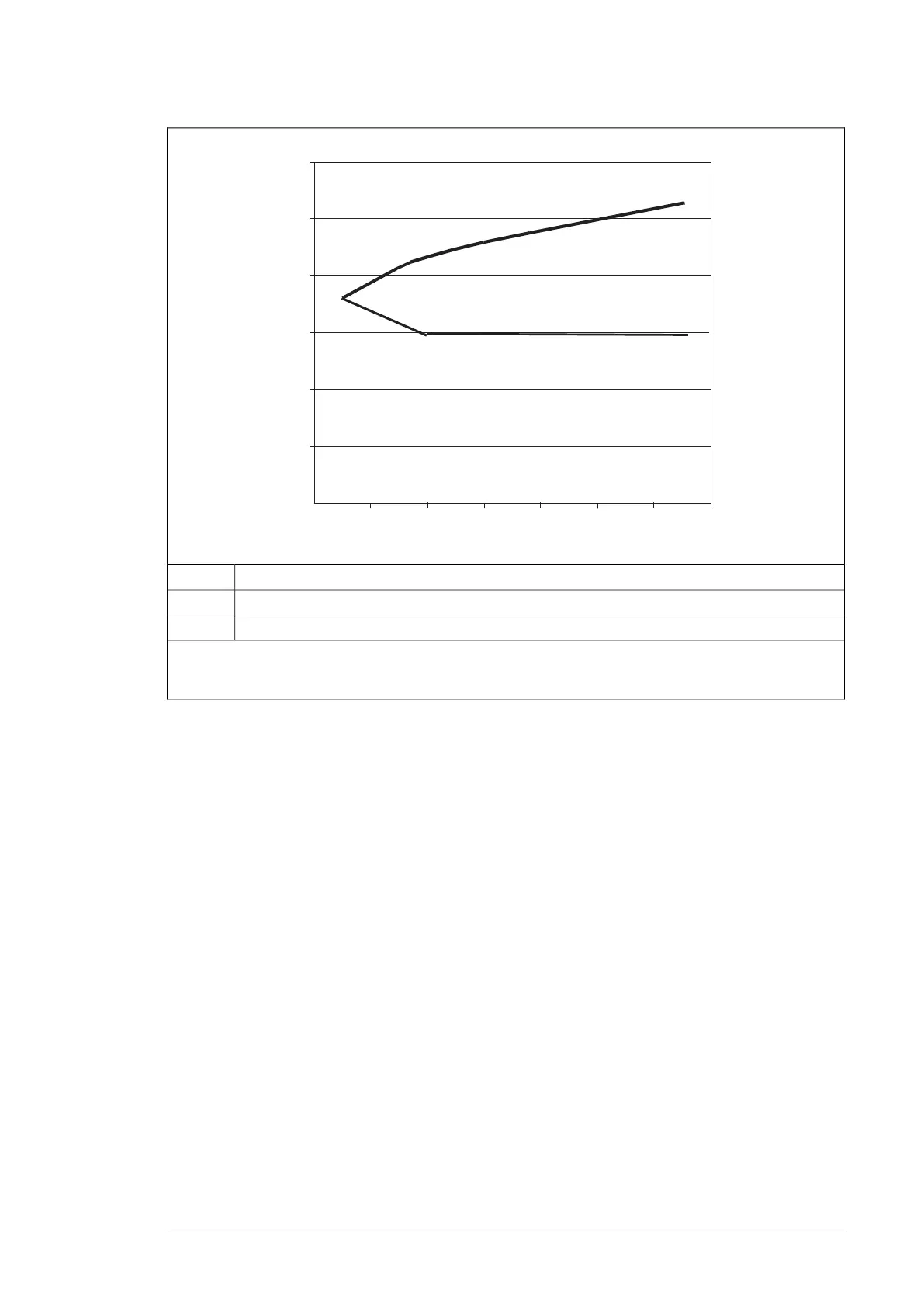

100 200 300

0.0

0.5

1.0

1.5

2.0

2.5

3.0

l (m)

du/dt

U

N

-------------(1/Ps)

Û

LL

/U

N

Motor cable length

I

Relative peak line-to-line voltage

Û

LL

/U

N

Relative du/dt value(du/dt)/U

N

Note:

Û

LL

and du/dt values are approximately 20% higher during resistor braking.

Selecting the power cables

■ General rules

Select the input power and motor cables according to local regulations. Obey these rules:

• Select a cable capable of carrying the nominal current.

• Select a cable rated for at least 70 °C maximum permissible temperature of conductor

in continuous use.

• The inductance and impedance of the PE conductor/cable (grounding wire) must be

rated according to permissible touch voltage appearing under fault conditions (so that

the fault point voltage will not rise excessively when a ground fault occurs).

• 600 V AC cable is accepted for up to 500 V AC. 750 V AC cable is accepted for up to

600 V AC. For 690 V AC rated equipment, the rated voltage between the conductors

of the cable should be at least 1 kV.

• With US installations, consider the additional US requirements.

Use symmetrical shielded input power cables. The cabling has to be identical (length and

cross-sectional area) between all the parallel-connected supply modules. Each module

must have its own shielded 3-conductor input AC cable with the minimum length of 5 m

(16.4 ft). This ensures uniform loading of all the three input phases. Single-conductor cables

cannot be used.

Guidelines for planning the electrical installation 71

Loading...

Loading...