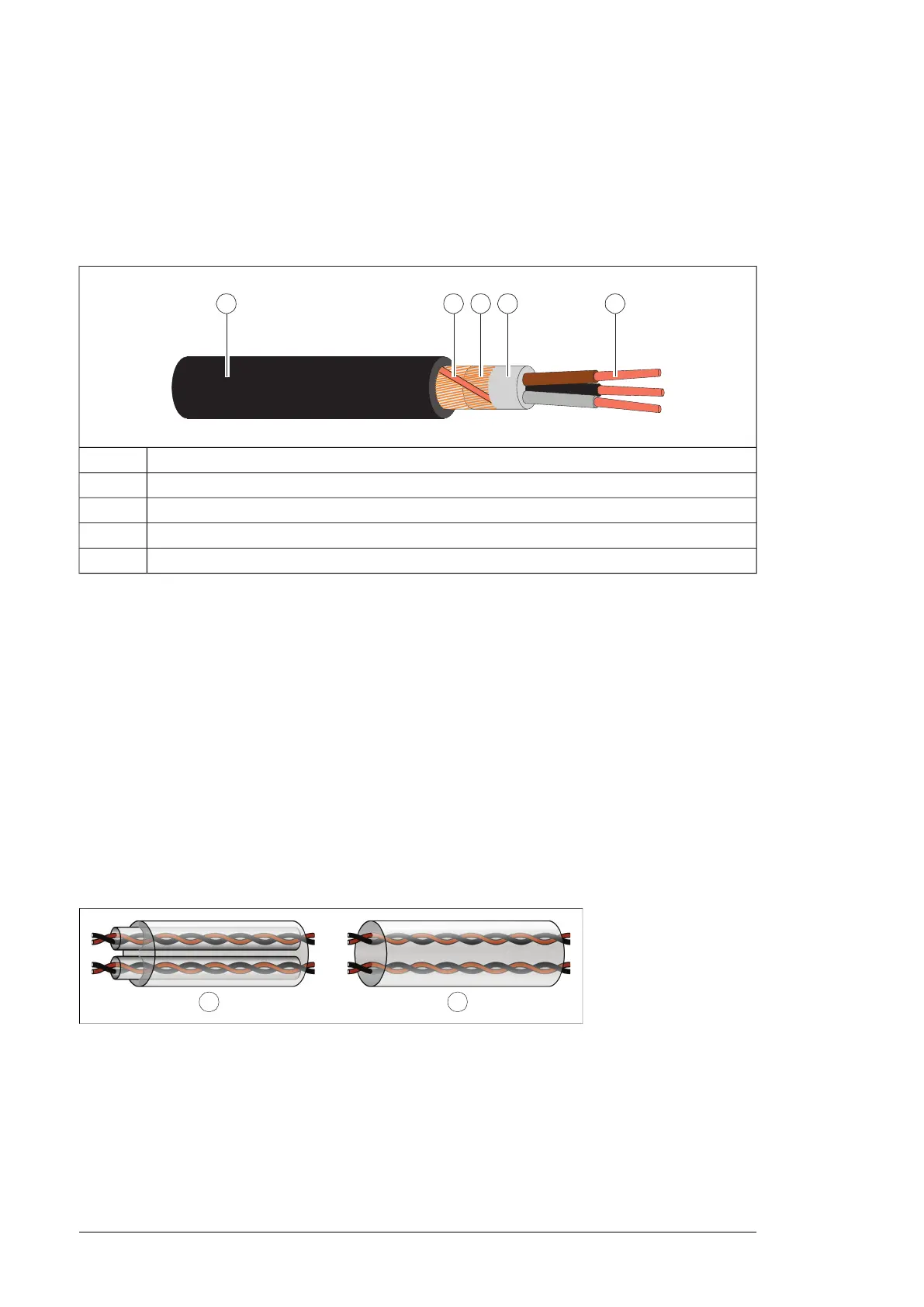

To effectively suppress radiated and conducted radio-frequency emissions, the cable shield

conductivity must be at least 1/10 of the phase conductor conductivity. The requirements

are easily met with a copper or aluminum shield. The minimum requirement of the motor

cable shield of the drive is shown below. It consists of a concentric layer of copper wires

with an open helix of copper tape or copper wire. The better and tighter the shield, the lower

the emission level and bearing currents.

Insulation jacket1

Helix of copper tape or copper wire2

Copper wire screen3

Inner insulation4

Cable core5

Planning the resistor braking system

See chapter Resistor braking (page 203).

Selecting the control cables

■ Shielding

All control cables must be shielded.

Use a double-shielded twisted pair cable for analog signals. This type of cable is

recommended for the pulse encoder signals also. Employ one individually shielded pair for

each signal. Do not use common return for different analog signals.

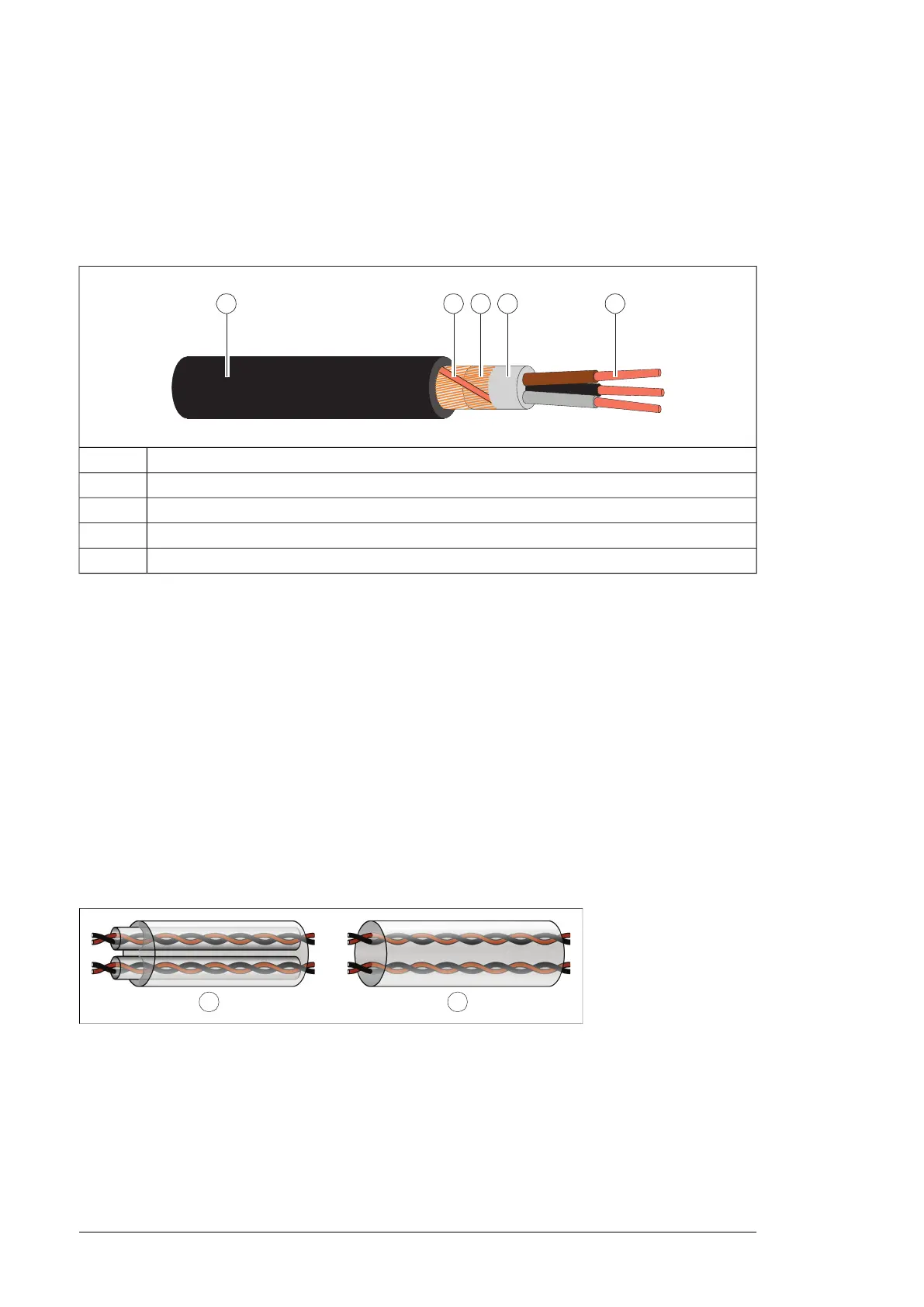

A double-shielded cable (figure a below) is the best alternative for low-voltage digital signals

but single-shielded (b) twisted pair cable is also acceptable.

■ Signals in separate cables

Run analog and digital signals in separate, shielded cables. Never mix 24 V DC and 115/230

V AC signals in the same cable.

■ Signals allowed to be run in the same cable

Relay-controlled signals, providing their voltage does not exceed 48 V, can be run in the

same cables as digital input signals. The relay-controlled signals should be run as twisted

pairs.

74 Guidelines for planning the electrical installation

Loading...

Loading...