Operation

multi EA 4000 Version 01.16 75

4. Change between the different analyzer modules, first activating the sensors:

− Select the menu item D

EVICE / DEVICE - EDIT.

− Activate "C" in the list E

LEMENTS.

− In the list C

OMBUSTION TUBE click on CERAMIC TUBE (CS).

− As S

TATES enable the option SOLID.

− Activate the E

JECTION RAIL option.

5. Initialize the system by clicking on [I

NITIALIZE ANALYZER].

6. Load a method (menu item M

ETHOD / METHOD - ACTIVATE) or create a new method

(menu item M

ETHOD / METHOD NEW).

Select the parameter TIC (detect TIC content only).

7. After the run-in time set the following gas flows:

2

2

approx. 1.7 l/min

corresponds to

TARGET = 100 ± 5 in the STATUS

window

1 l/min 1.5 l/min

*Caution:

Argon is not required for this mode, oxygen is automatically present at the rotameter

"Ar/O

2

".

The analysis system now has time for conditioning.

If the intake flow differs greatly or changes subsequently, re-adjust it at the "pump"

valve of the multi EA 4000.

8. Weigh the sample on ceramic boat.

9. Start the measurement by clicking on [S

TART MEASUREMENT].

10. Create or select an analysis group for storing the measuring data.

11. Create an analysis sequence.

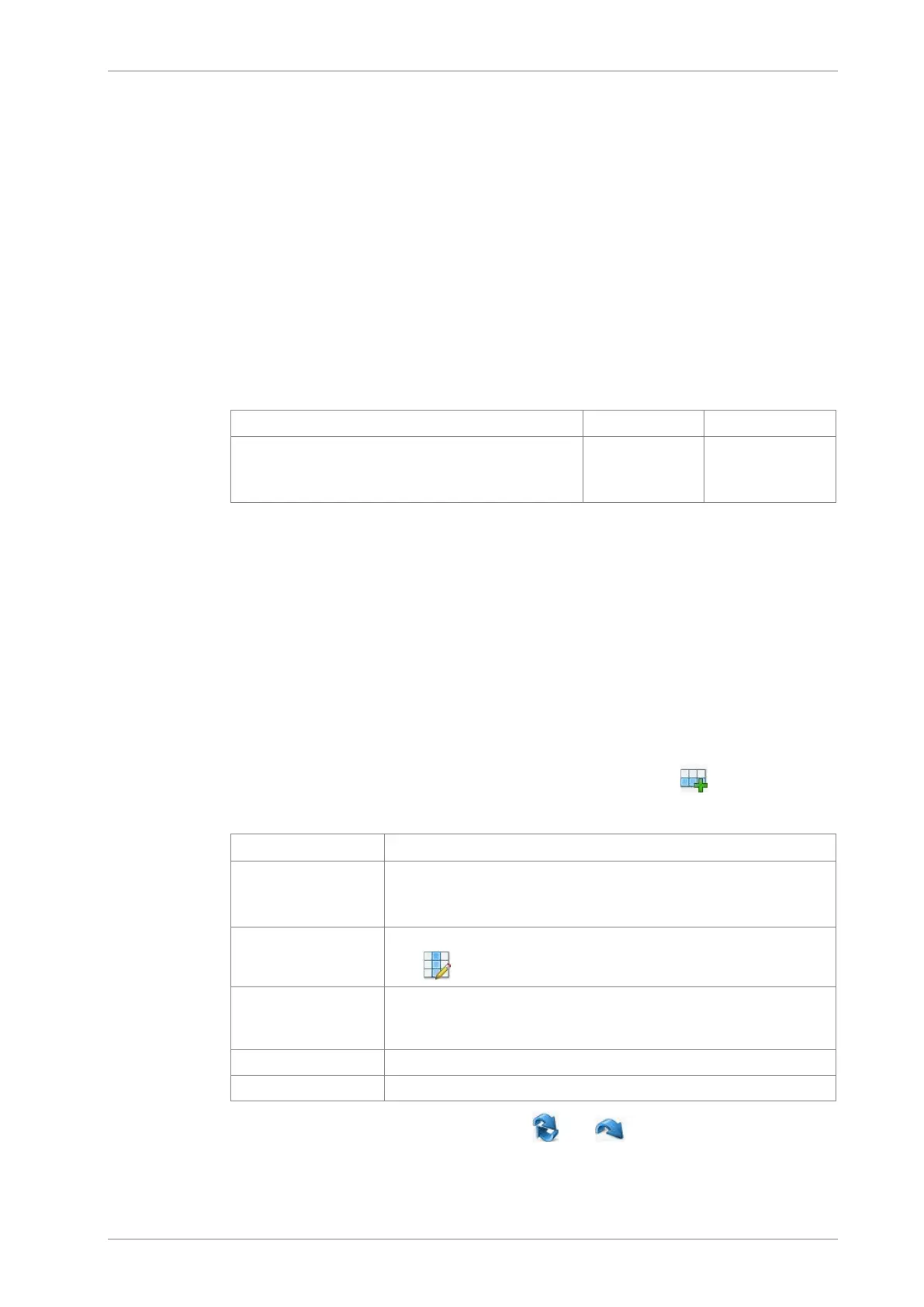

− Add the desired number of samples to the sample table with .

− Enter the following data:

Column Description

SAMPLE POSITION Position of the sample on the sample rack.

The sample rack assignment may only take place with ascend-

ing position numbers. However, it need not be without gaps.

NAME Sample ID

With an automatic sample ID can be generated.

ANALYSIS TYPE Selection of the analysis type (SAMPLE, DAILY FACTOR,

CALIBRATION MEASUREMENT, AQ A MEASUREMENT or BOAT BLANK

DETERMINATION

)

NOMINAL VALUE Target concentration for calibration standards or AQA standard

Operands Entry of the weighted sample

− Populate the sampler. Use the buttons and to move the sample rack into

the desired position.

Loading...

Loading...