Operation

74 Edition 01/2016 multi EA 4000

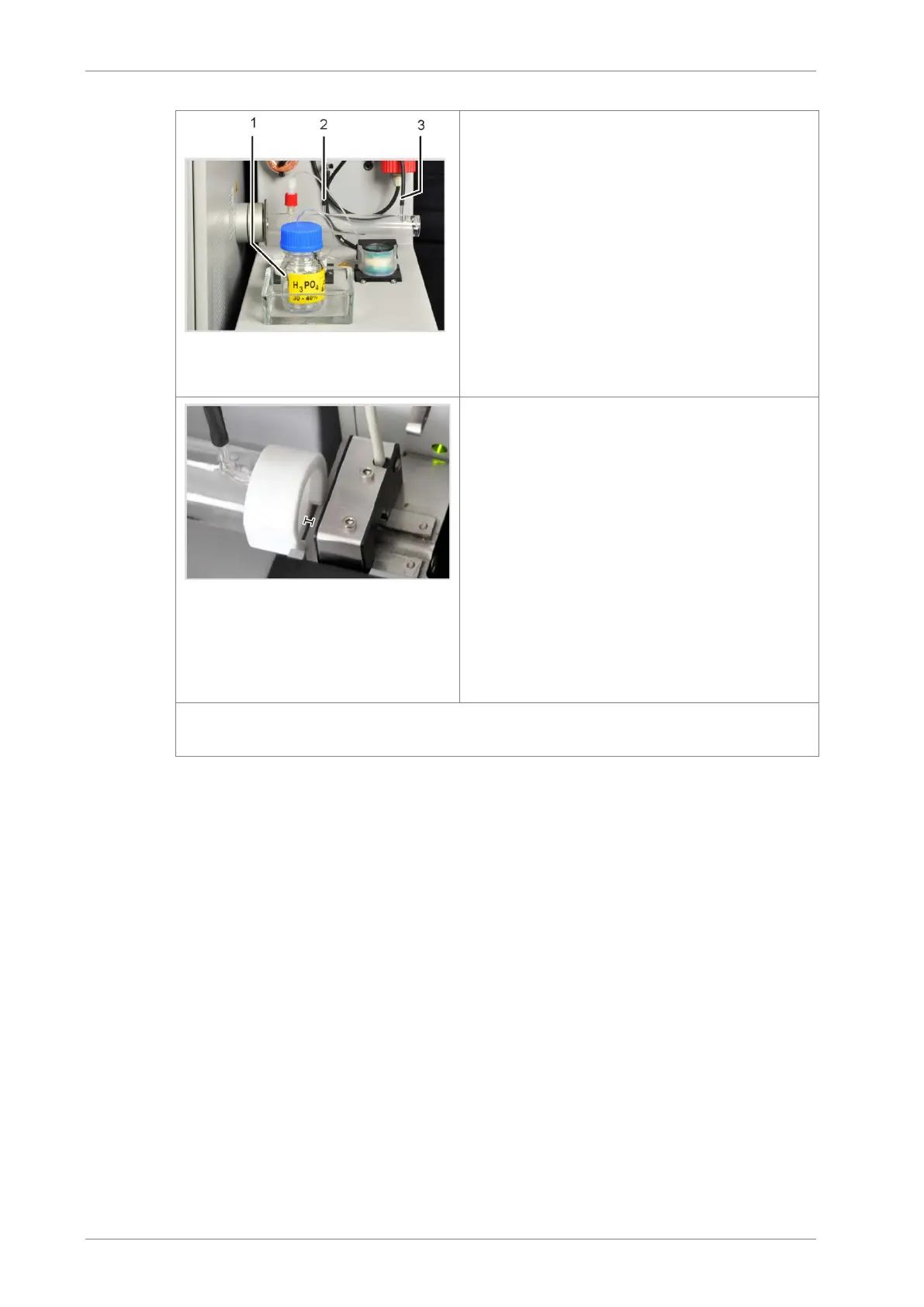

6. Connect the measuring outlet (2) to the top

end of the cooling coil on the rear of the TIC

solids module.

7. Slide the hose for the oxygen supply (3 in

Fig. 7 p. 25) onto the reactor connection for

the carrier gas (3).

Caution:

Always support the reactor with one hand

whilst attaching the hoses. If there is too

much pressure on the gas cylinder from one

side, the TIC reactor can break.

8. Place the reagent tray with the acid bottle

into a drip tray in front of the acid pump.

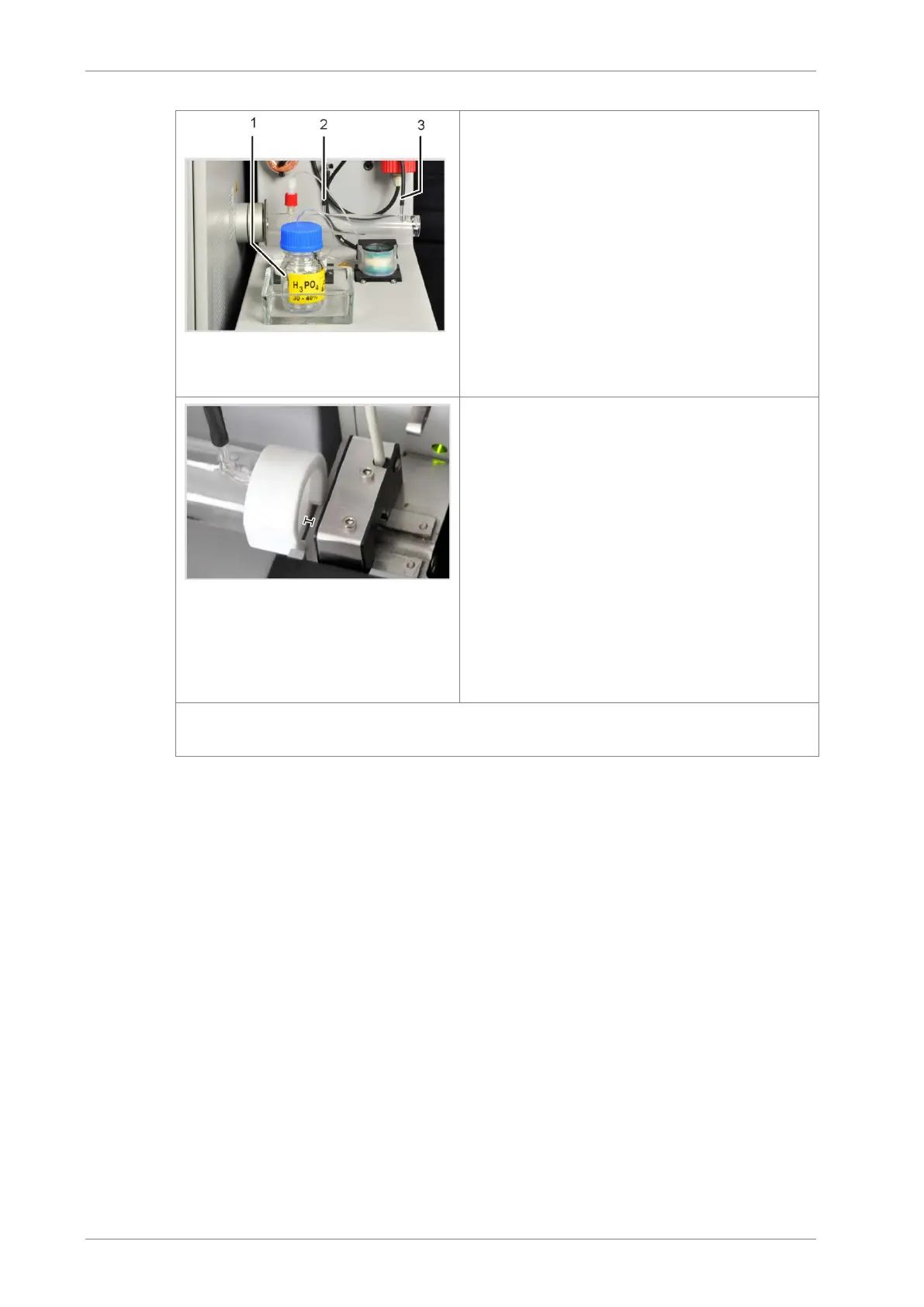

9. Slide the white PTFE ring onto the end of the

TIC reactor.

10. Place the converted sampler FPG 48 (see

section "Fehler! Verweisquelle konnte

nicht gefunden werden." p. Fehler!

Textmarke nicht definiert.) near the TIC

solids module. The TIC reactor with the PTF

ring rests on the edge of the sampler.

Align the sampler until the ceramic boat can

be moved straight into the reactor and fur-

ther into the furnace during TOC measure-

ments. A gap of 2 - 4 mm must remain be-

tween the TIC reactor and the sampler to

prevent tension from the thermal expansion

of the ceramic tube.

11. To the right of the FPG 48 below the ejection rail place a container for the used ce-

ramic boats.

7.5.2 Required reagents

The following reagents are required for the TIC detection:

40% ortho-phosphoric acid (for recommended differential method)

10% hydrochloric acid for TOC detection (for direct method)

7.5.3 Performing the TIC detection with the automatic TIC solids

module

1. In the acid bottle of the TIC solids module keep ortho-phosphoric acid ready.

2. Switch on the basic device multi EA 4000, the C/S module, the automatic TIC solids

module and the FPG 48 from the main switch.

The status lamps at the device front panels illuminate.

Note: Do not switch on any Cl module present.

3. Start the multiWin program.

Loading...

Loading...