Maintenance and care

multi EA 4000 Version 01.16 95

8.4 Operation with automatic TIC solids module

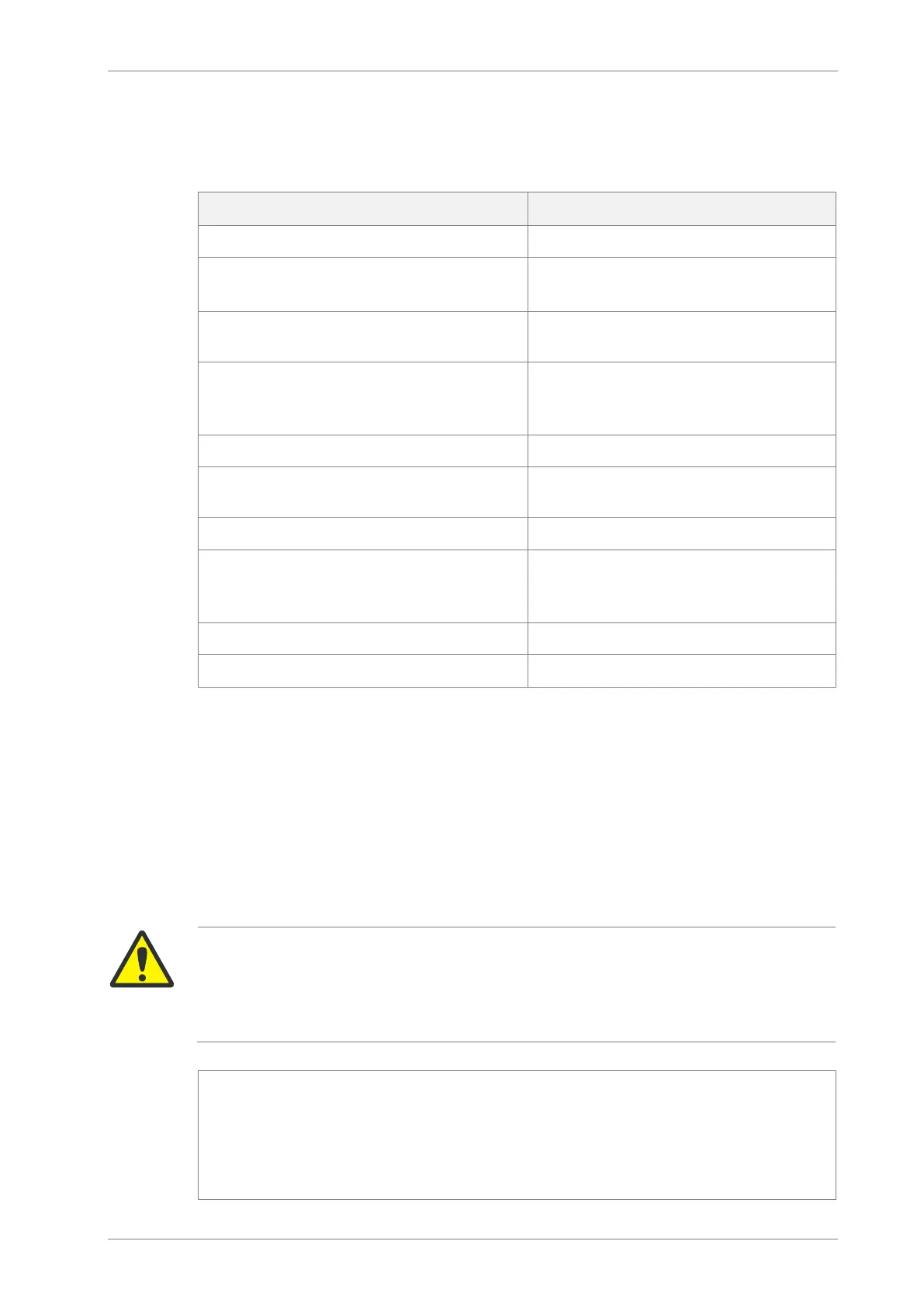

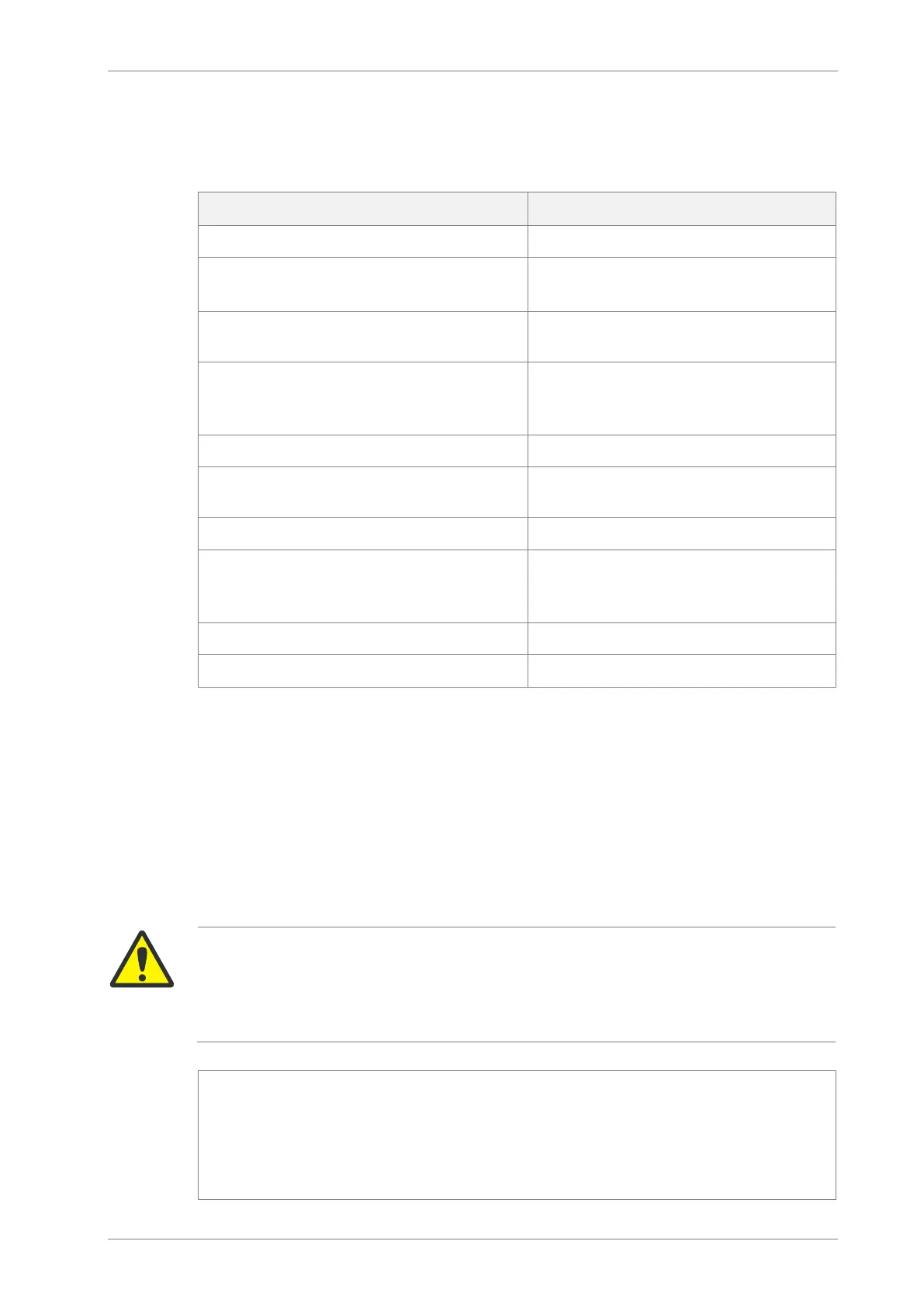

Maintenance intervals

Remove chemical splashes from the housing immediately

Clean the TIC reactor daily,

in case of visible contamination

Replace the desiccant in the drying tube as required (blackening or clumping due

to moisture absorption)

Replace the halide trap if necessary,

if half of the copper wool or the brass

wool is discolored

Check the condensation coil for damage after 3 months

Clean the condensation coil as required, but no later than after 12

months

Check the condensate container for damage after 3 months

Clean the condensate container

as required, but no later than after 12

months

Replace metering pump, pump hose after 3 months

Replace condensate pump, pump hose after 3 months

Replace the desiccant in the drying tube in the same manner as in the basic device multi EA

4000 ( see section "Replacing the desiccant in the drying tube" p. 88).

Also replace the copper and brass wool in the halide trap analog to the replacement of the

halide trap in the basic device in the multi EA 4000 ( see section "Replacing the halide

trap" p. 89).

8.4.1 Clean the TIC reactor of the automatic TIC solids module

WARNING

The phosphoric acid or

hydrochloric acid used to purge the TIC can cause severe chemical

Always wear protective gloves and goggles when handling concentrated acid! Rinse spilla

g-

es on the skin immediately.

1. Switch off the basic device and the TIC module from the mains switch. Switch off the

gas supply.

2. Allow the device to cool down sufficiently (at least 2h).

3. Move the FPG 48 approx. 30 cm to the right to make space for removing the TIC

reactor.

Loading...

Loading...