ANDREOLI ENGINEERING

Operator’s Manual

Self-propelled sprayer ATOM

7.3 AXLES

7.3.1 Lubricants table

Lubricants

SAE 85W90 (API GL4) suitable for brakes immerged in oil.

Example of oils suitable : Mobil Super Universal 20W40, Mobil Fluid 422, ELF SF3, AGIP

MULTI THT 80W

For axles with differential lock :

SAE 85W90 (API GL5) suitable for brakes immerged in oil and diff. lock (LS Limited Slip).

Example of oils suitable : SHELL SPIRAX HD 85W90, FUCHS TITAN GEAR 85W90 LS,

CASTROL LSC SAE 90, ELF SF3

Recommended in both cases “Shell Donax TD”.

Brake oil

For brake equipment use exclusively mineral oil “Agip ATF II D” or eventually oils ATF Dexron II

Grease

Recommended grease “Shell Retinax HDX2”.

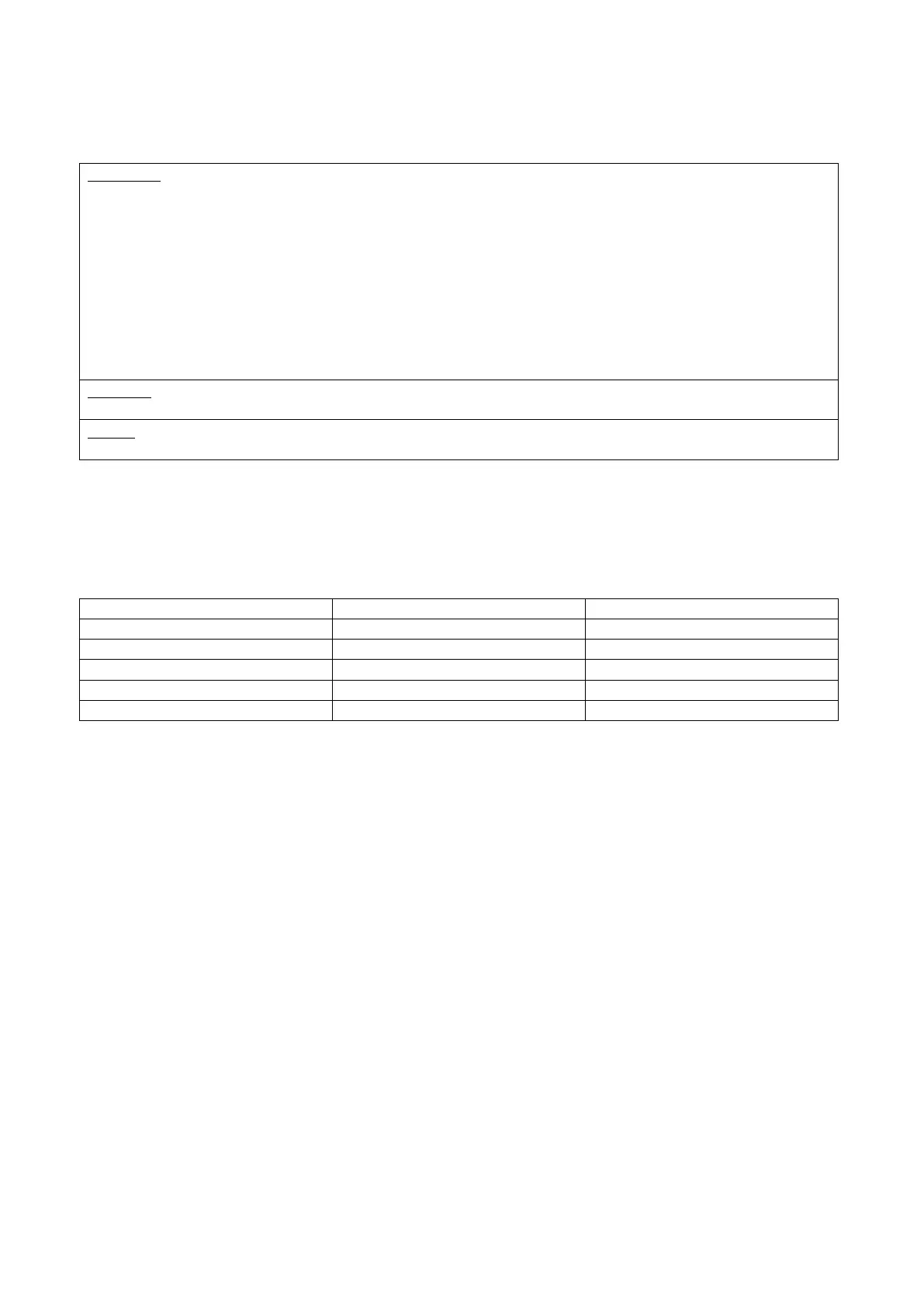

7.3.2 Maintenance intervals

The maintenance intervals indicated are suggested for a normal use of the machine, it is necessary to increase

the frequency of the intervals in case of heavy use.

Every Year / 600 hours (1)

Cleaning magnetic oil plug

Every month / 300 hours (1)

Every month / 300 hours (1)

Every week / 200 hours (1)(2)

(1) the first that may occur

(2) 50 hours in case of heavy use

Loading...

Loading...