ANDREOLI ENGINEERING

Operator’s Manual

Self-propelled sprayer ATOM

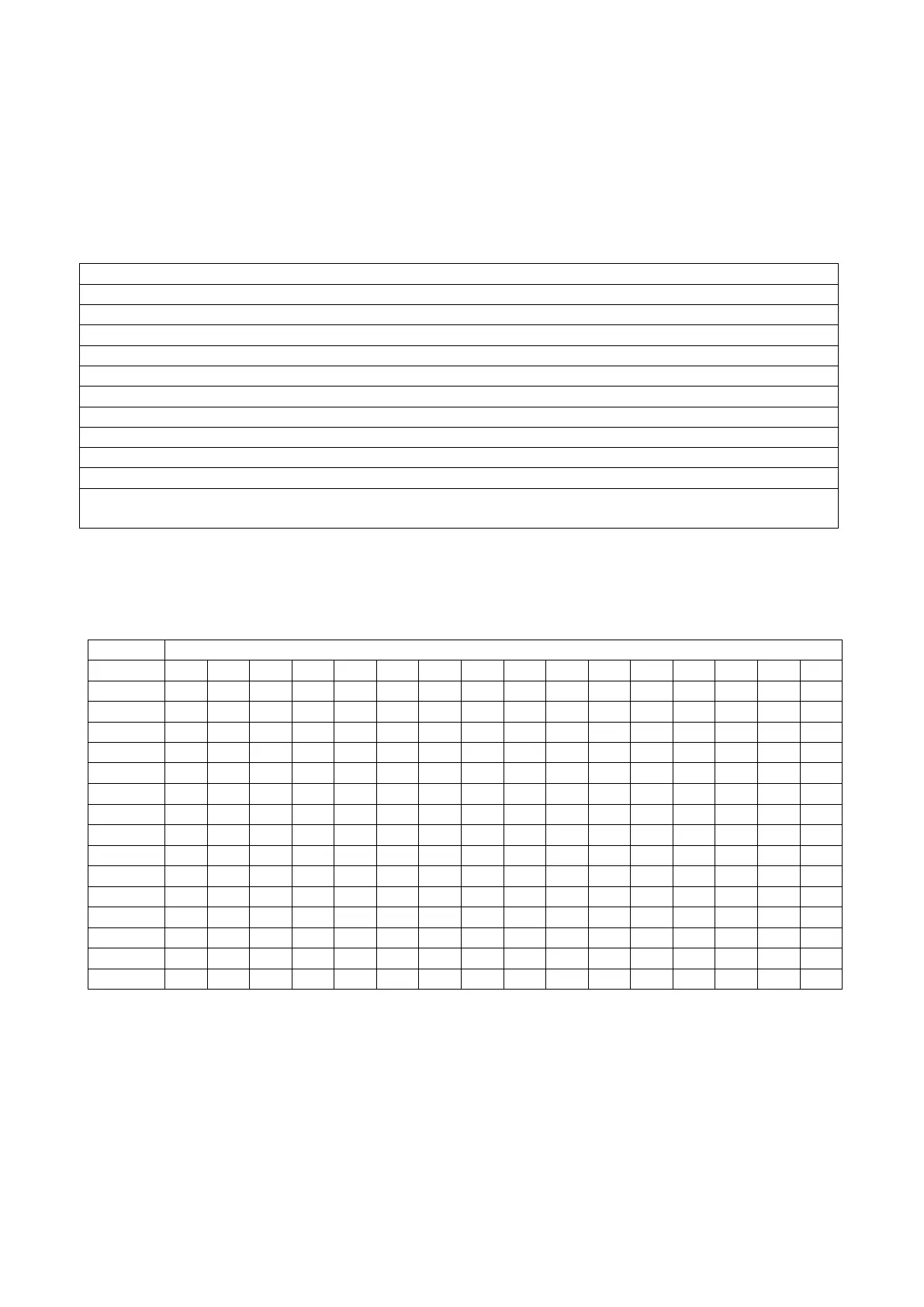

5.2 SPRAY RATES PARAMETERS SELECTION CRITERIA

The spray rate selection is based on formulas explained in the following tables.

To select the correct parameters it is necessary to know the following data:

1) quantity of mixture (chemicals) per surface unit: [liters/hectare] or [gallons/acre];

2) quantity of mixture sprayed by each nozzle per minute [liters/min] or [gallons/min];

3) row spacing distance [m] or [feet];

4) working speed [km/h] or [miles/h].

Spray rate required = 600 litres/hectare

Working speed = 100 m/minute

10000 / row spacing = 2500 linear m

2500 / working speed = 25 minutes of spray

Spray rate required / 25 = 24 litres/minute = total nozzle emission flow

Number of active nozzles = 14

Total nozzle emission flow / 14 = 1,71 litres/minute per each nozzle

CHECK THE NOZZLE CORES TABLES

Nozzle to be used = red

Working pressure = 8 bar

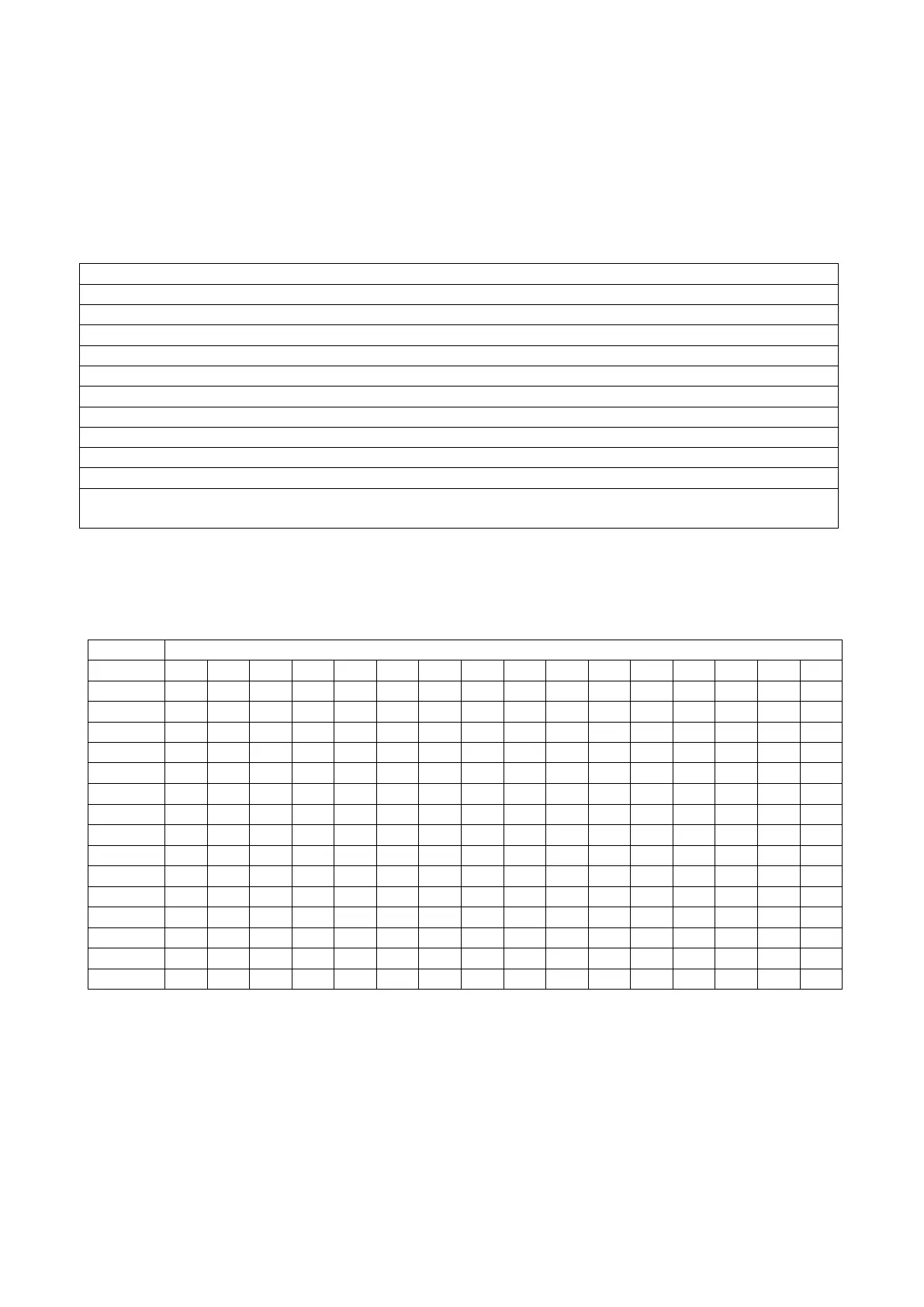

5.2.1 Spray rates table for Albuz pink ceramic discs cores

P= ceramic disc nozzle

C = Swirl plate with central hole

C.c. = Swirl plate without central hole

Loading...

Loading...