DL205 User Manual, 4th Edition, Rev. D

2-16

Chapter 2: Installation, Wiring and Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

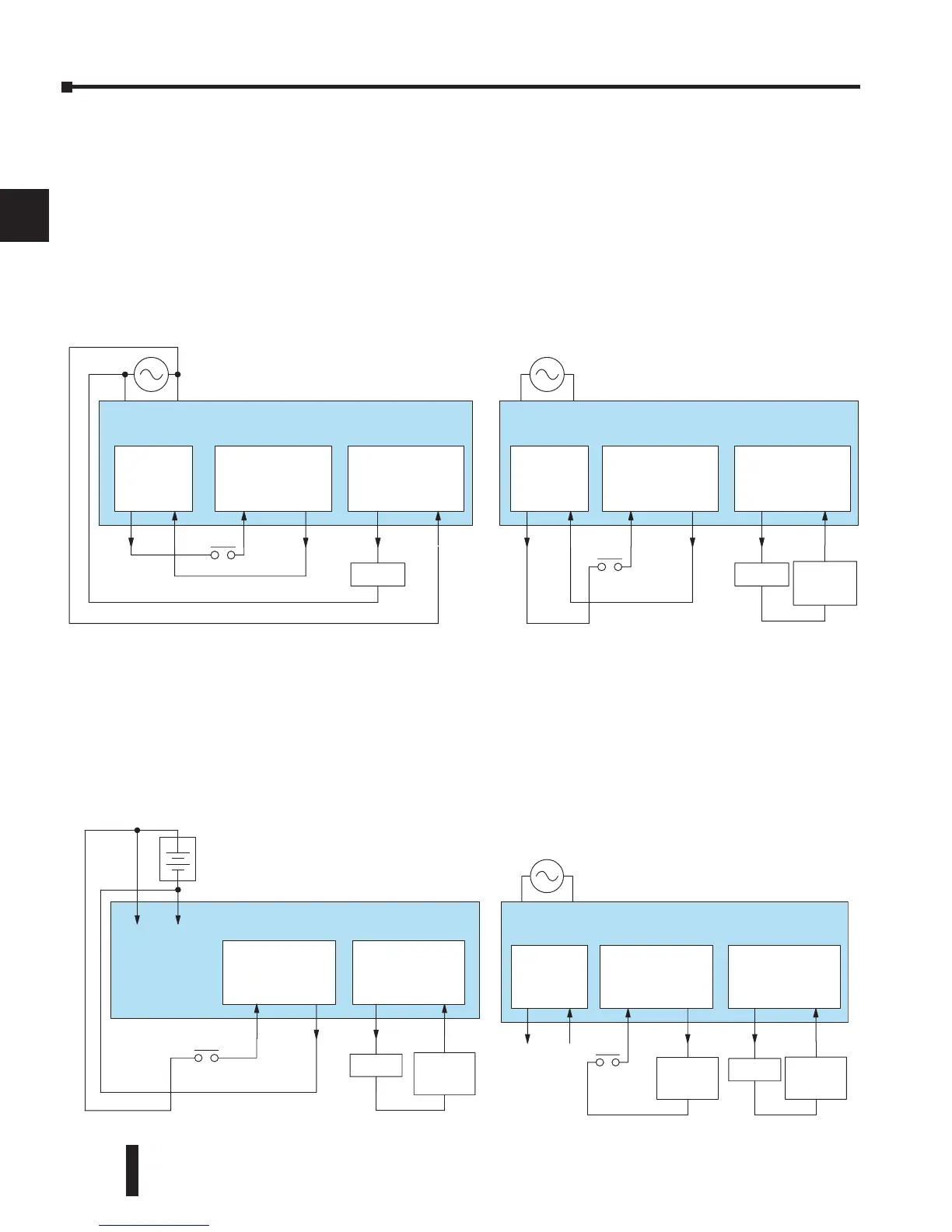

Powering I/O Circuits Using Separate Supplies

In most applications it will be necessary to power the input devices from one power source, and

to power output loads from another source. Loads often require high-energy AC power, while

input sensors use low-energy DC. If a machine operator is likely to come in close contact with

input wiring, then safety reasons also require isolation from high-energy output circuits. It is

most convenient if the loads can use the same power source as the PLC, and the input sensors

can use the auxiliary supply, as shown to the left in the figure below.

If the loads cannot be powered from the PLC supply, then a separate supply must be used as

shown to the right in the figure below.

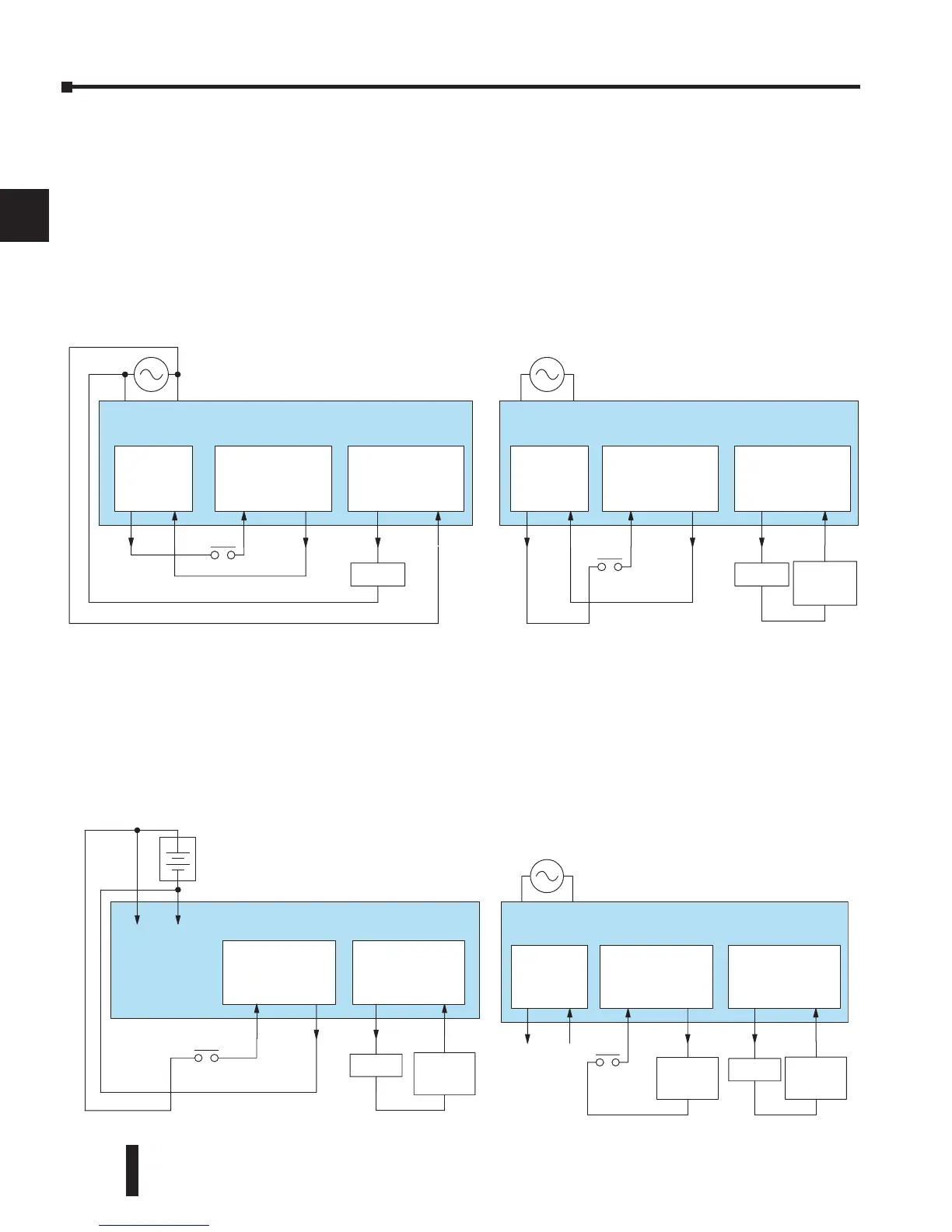

Some applications will use the PLC external power source to also power the input circuit. This

typically occurs on DC-powered PLCs, as shown in the drawing below to the left. The inputs

share the PLC power source supply, while the outputs have their own separate supply. A worst-

case scenario, from a cost and complexity viewpoint, is an application which requires separate

power sources for the PLC, input devices, and output loads. The example wiring diagram

below on the right shows how this can work, but also the auxiliary supply output is an unused

resource. You will want to avoid this situation if possible.

Input Module

Auxiliary

+24VDC

Supply

Power Input

DL205 PLC

Output Module

Loads

AC Power

+

–

Inputs Com. Outputs Com.

Input Module

Auxiliary

+24VDC

Supply

Power Input

DL205 PLC

Output Module

Loads

AC Power

+

–

Inputs Com. Outputs Com.

Load

Supply

Input Module

Power Input

DL205 PLC

Output Module

Loads

DC Power

+

–

+

–

Inputs Com. Outputs Com.

Load

Supply

Input Module

Auxiliary

+24VDC

Supply

Power Input

DL205 PLC

Output Module

Loads

AC Power

+

–

Inputs Com. Outputs Com.

Load

Supply

Input

Supply

Loading...

Loading...