DL205 User Manual, 4th Edition, Rev. D

4-2

Chapter 4: System Design and Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

DL205 System Design Strategies

I/O System Configurations

The DL205 PLCs offer the following ways to add I/O to the system:

• Local I/O – consists of I/O modules located in the same base as the CPU.

• Local Expansion I/O – consists of I/O modules in expansion bases located close to the CPU local

base. Expansion cables connect the expansion bases and CPU base in daisy–chain format.

• Ethernet Remote Master – provides a low-cost, high-speed Ethernet Remote I/O link to Ethernet

Remote Slave I/O.

• Ethernet Base Controller – provides a low-cost, high-speed Ethernet link between a network master

to AutomationDirect Ethernet Remote Slave I/O.

• Remote I/O – consists of I/O modules located in bases which are serially connected to the local CPU

base through a Remote Master module, or may connect directly to the bottom port on a DL250–1

or DL260 CPU.

A DL205 system can be developed using many different arrangements of these configurations.

All I/O configurations use the standard complement of DL205 I/O modules and bases. Local

expansion requires using (–1) bases.

Networking Configurations

The DL205 PLCs offers the following way to add networking to the system:

• Ethernet Communications Module – connects DL205 systems (DL240, DL250–1 or DL260

CPUs only) and DL405 CPU systems in high–speed, peer–to–peer networks. Any PLC can initiate

communications with any other PLC when using either the ECOM or ECOM100 modules.

• Data Communications Module – connects a DL205 (DL240, DL250–1 and DL260 only) system

to devices using the DirectNET protocol, or connects as a slave to a Modbus RTU network.

• DL250–1 Communications Port – The DL250–1 CPU has a 15–Pin connector on Port 2 that

provides a built–in Modbus RTU or DirectNET master/slave connection.

• DL260 Communications Port – The DL260 CPU has a 15–Pin connector on Port 2 that provides

a built–in DirectNET master/slave or Modbus RTU master/slave connection with more Modbus

function codes than the DL250–1. (The DL260 MRX and MWX instructions allow you to

enter native Modbus addressing in your ladder program with no need to perform octal to decimal

conversions.) Port 2 can also be used for ASCII IN or ASCII OUT communications.

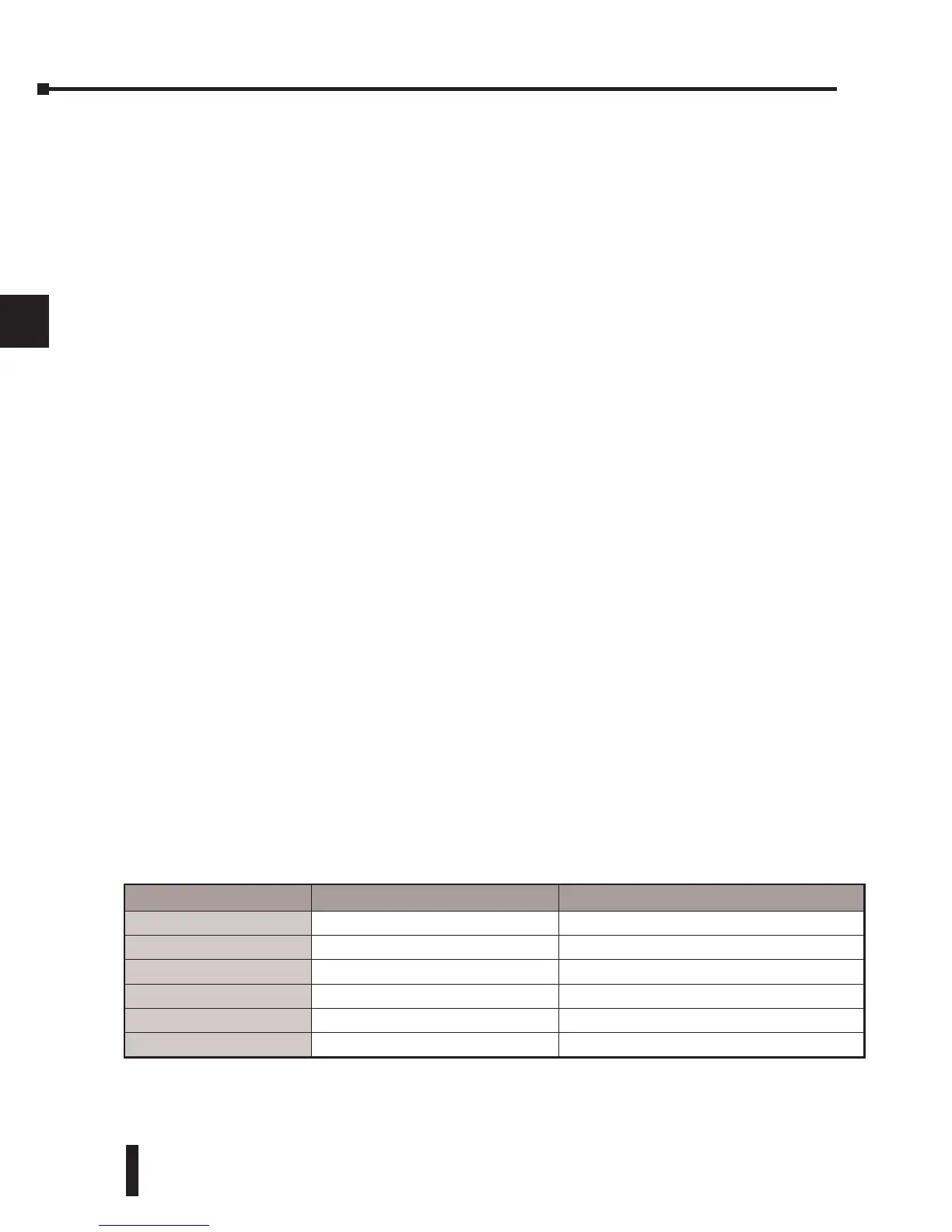

Module/Unit Master Slave

DL240 CPU

DirectNet, K–Sequence

DL250–1 CPU

DirectNet, Modbus RTU DirectNet, K–Sequence, Modbus RTU

DL260 CPU

DirectNet, Modbus RTU, ASCII DirectNet, K–Sequence, Modbus RTU, ASCII

ECOM

Ethernet Ethernet

ECOM100

Ethernet, Modbus TCP Ethernet, Modbus TCP

DCM

DirectNet DirectNet, K–Sequence, Modbus RTU

Loading...

Loading...