DL205 User Manual, 4th Edition, Rev. D

4-35

Chapter 4: System Design and Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

Network Slave Operation

This section describes how other devices on a network can communicate with a CPU port that

you have configured as a DirectNET slave (DL240/250–1/260) or Modbus slave (DL250–1,

DL260). A Modbus host must use the Modbus RTU protocol to communicate with the

DL250–1 or DL260 as a slave. The host software must send a Modbus function code and

Modbus address to specify a PLC memory location the DL250–1 or DL260 comprehends.

The DirectNET host uses normal I/O addresses to access applicable DL205 CPU and system.

No CPU ladder logic is required to support either Modbus slave or DirectNET slave operation.

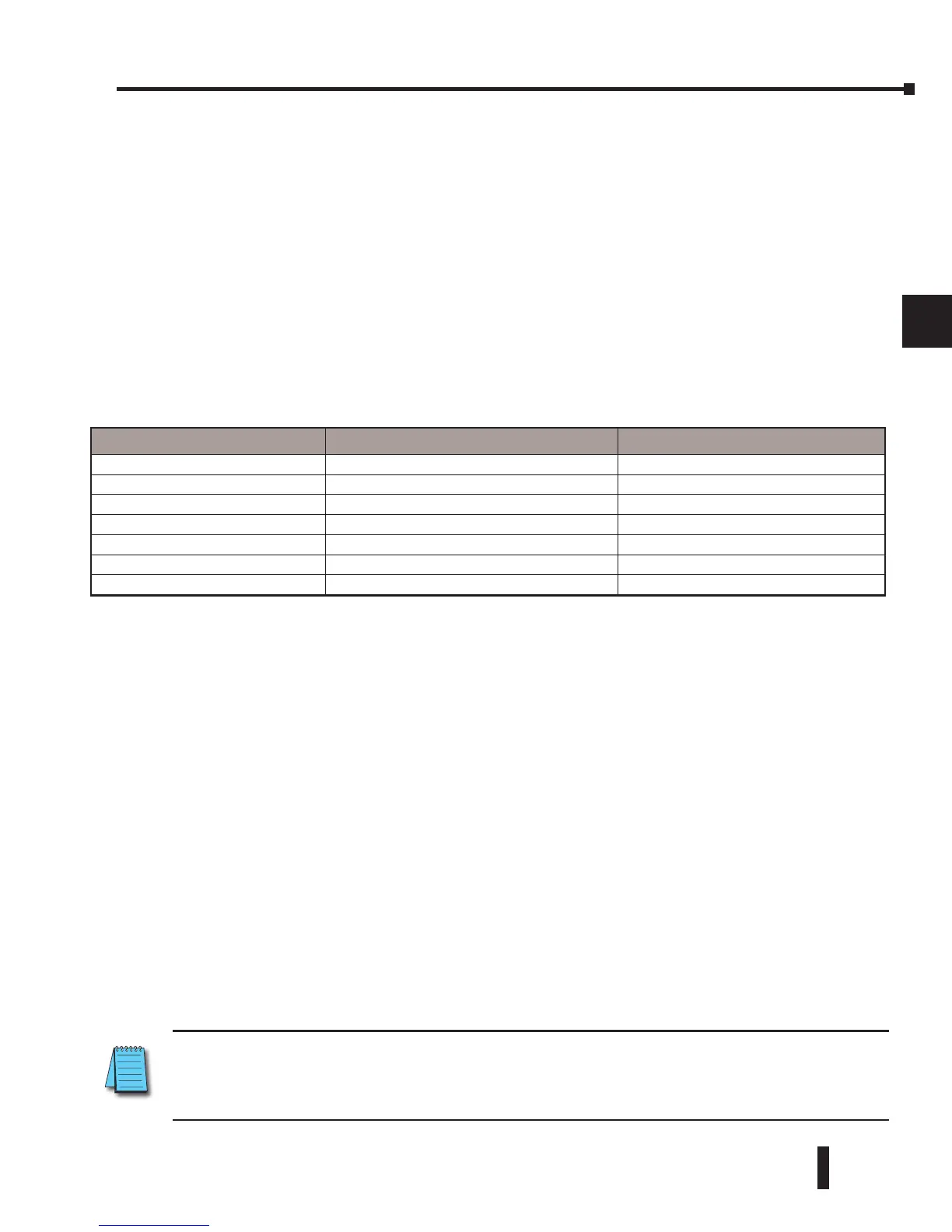

Modbus Function Codes Supported

The Modbus function code determines whether the access is a read or a write, and whether to

access a single data point or a group of them. The DL250–1 and DL260 support the Modbus

function codes described below.

Determining the Modbus Address

There are typically two ways that most host software conventions allow you to specify a PLC

memory location. These are:

• By specifying the Modbus data type and address

• By specifying a Modbus address only.

If Your Host Software Requires the Data Type and Address

Many Host software packages allow you to specify the Modbus data type and the Modbus

address that correspond to the PLC memory location. This is the easiest method, but not all

packages allow you to do it this way.

The actual equation used to calculate the address depends on the type of PLC data you are

using. The PLC memory types are split into two categories for this purpose.

• Discrete – X, SP, Y, C, S, T (contacts), CT (contacts)

• Word – V, Timer current value, Counter current value

In either case, you basically convert the PLC octal address to decimal and add the appropriate

Modbus address (if required). The table on the following page shows the exact equation used

for each group of data.

NOTE: For information about the Modbus protocol see www.Modbus.org and select Technical Resources.

For more information about the DirectNET protocol, order our DirectNET User Manual, DA-DNET-M, or

download the manual free from our website: www.automationdirect.com. Select Manuals/Docs>Online

User Manuals>Misc.>DA-DNET-M

Modbus Function Code Function DL205 Data Types Available

01 Read a group of coils Y, C, T, CT

02 Read a group of inputs X, SP

05 Set / Reset a single coil (slave only) Y, C, T, CT

15 Set / Reset a group of coils Y, C, T, CT

03, 04 Read a value from one or more registers V

06 Write a value into a single register (slave only) V

16 Write a value into a group of registers V

230

240

Loading...

Loading...