DL205 User Manual, 4th Edition, Rev. D

4-31

Chapter 4: System Design and Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

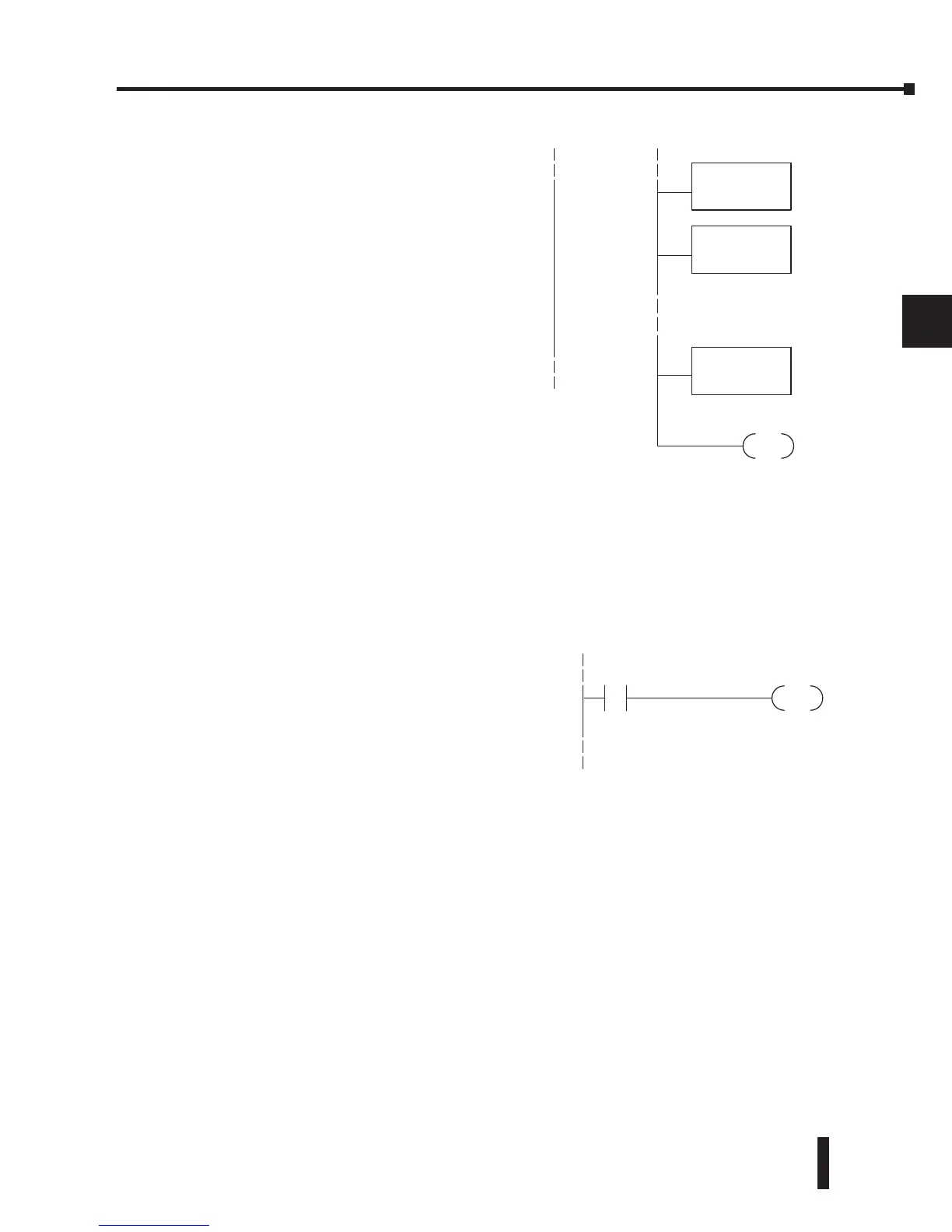

When configuring a Remote I/O channel for

fewer than 7 slaves, we must fill the remainder

of the table with zeros. This is necessary

because the CPU will try to interpret any non-

zero number as slave information.

We continue our set-up program from the

previous page by adding a segment which

fills the remainder of the table with zeros.

The example to the right fills zeros for slave

numbers 2–7, which do not exist in our

example system.

On the last rung in the example program above, we set a special relay contact C740. This

particular contact indicates to the CPU the ladder program has finished specifying a remote

I/O system. At that moment, the CPU begins remote I/O communications. Be sure to include

this contact after any Remote I/O set-up program.

Remote I/O Test Program

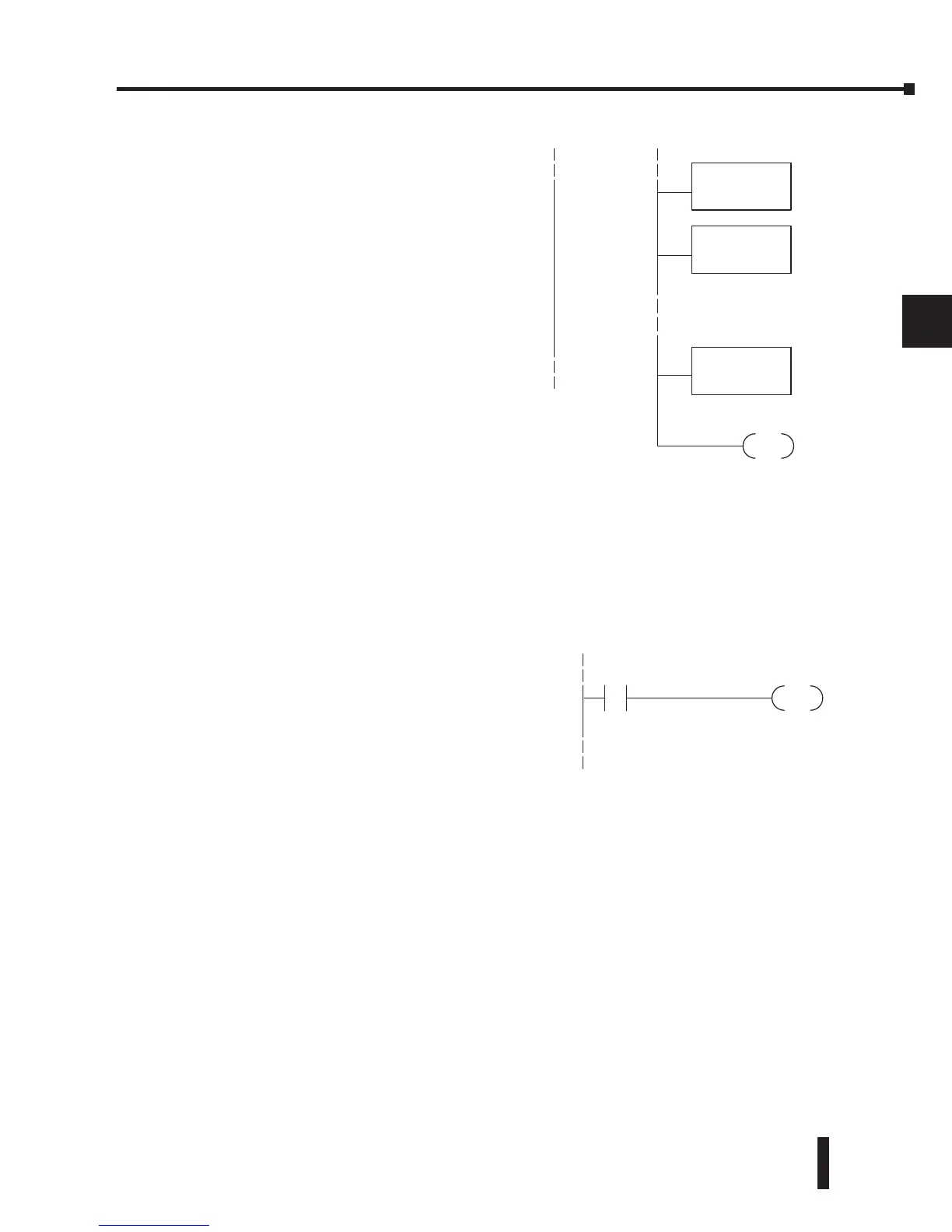

Now we can verify the remote I/O link and

set-up program operation. A simple quick

check can be done with one rung of ladder,

shown to the right. It connects the first input

of the remote base with the first output. After

placing the PLC in RUN mode, we can go

to the remote base and activate its first input.

Then its first output should turn on.

X60

DirectSOFT

OUT

Y40

LD

K0

OUTD

V37710

OUTD

V37736

Loading...

Loading...