105

5.1.2.6. Changing the Z motor

a) Remove the arm housing.

b) Remove the 4 screws that hold the motor in position from the back of the spring-encoder unit.

c) Remove the protective plate from the motor connector and the encoder photodetector.

d) Remove the photodetector from the encoder and disconnect the cables.

e) Remove the unit made up of the Z motor and the spring-encoder unit.

f) Loosen the Allen bolt on the encoder, located in the unit support body. You may have to turn the encoder with a

screwdriver at the back to direct the Allen bolt with an opening in the housing so that the key can enter.

g) Remove the fastening part that joins the motor with the support body.

h) Change the motor unit with pulley for a new one.

i) Introduce the back shaft of the motor into the encoder until it hits the back. Put screwfastener on the Allen bolt on the

encoder and make sure that it is fixed to the flat part of the motor shaft.

j) Mount the fastening part that joins the motor with the support body.

k) Mount the unit made up by the motor and the spring-encoder on the Y carriage. Do not fully tighten the 6 screws that

hold the Y carriage to the unit.

l) Mount the photodetector on the encoder and connect the cables.

m)Mount the protection sheeting on the photodetector of the encoder and the motor connector.

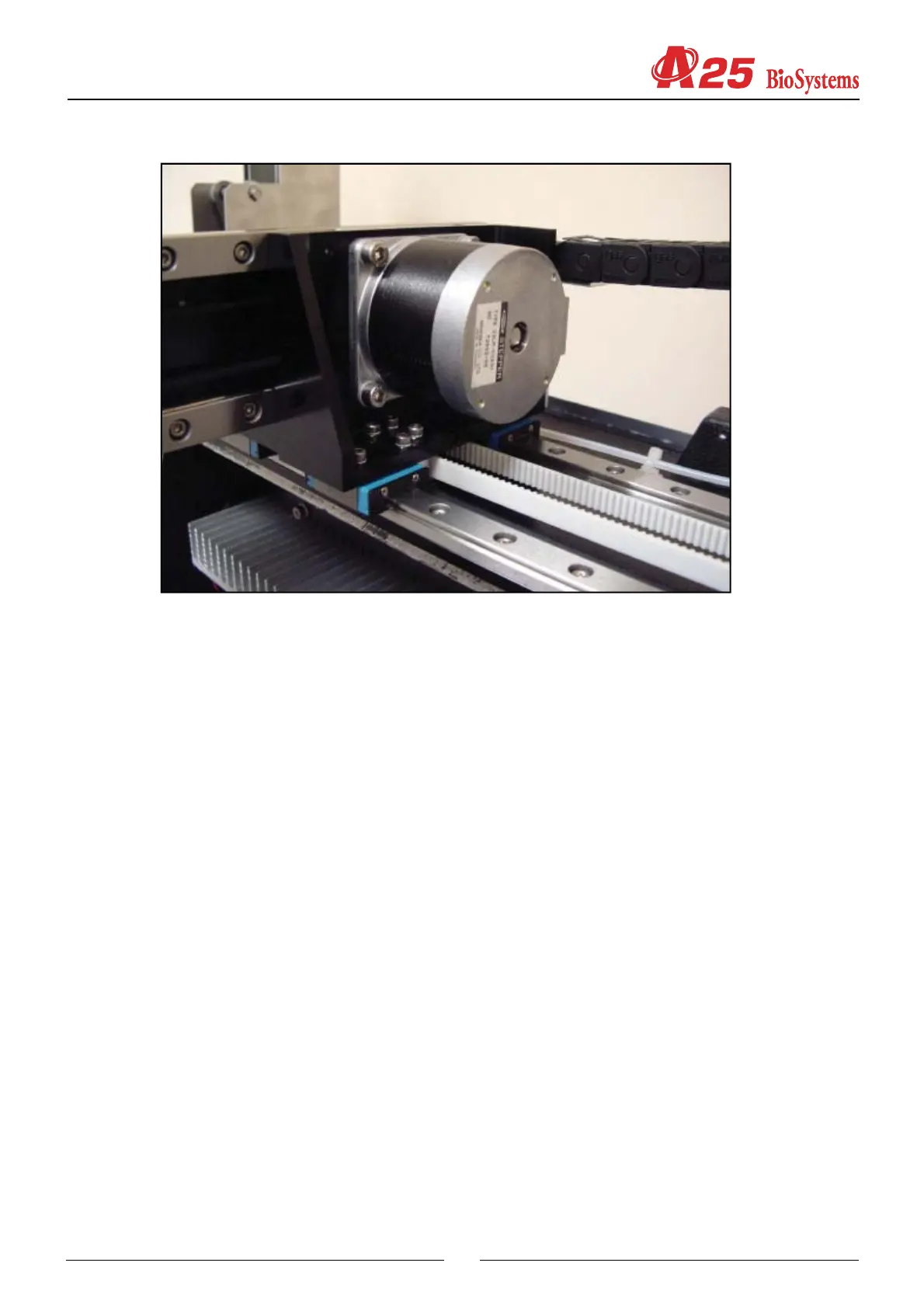

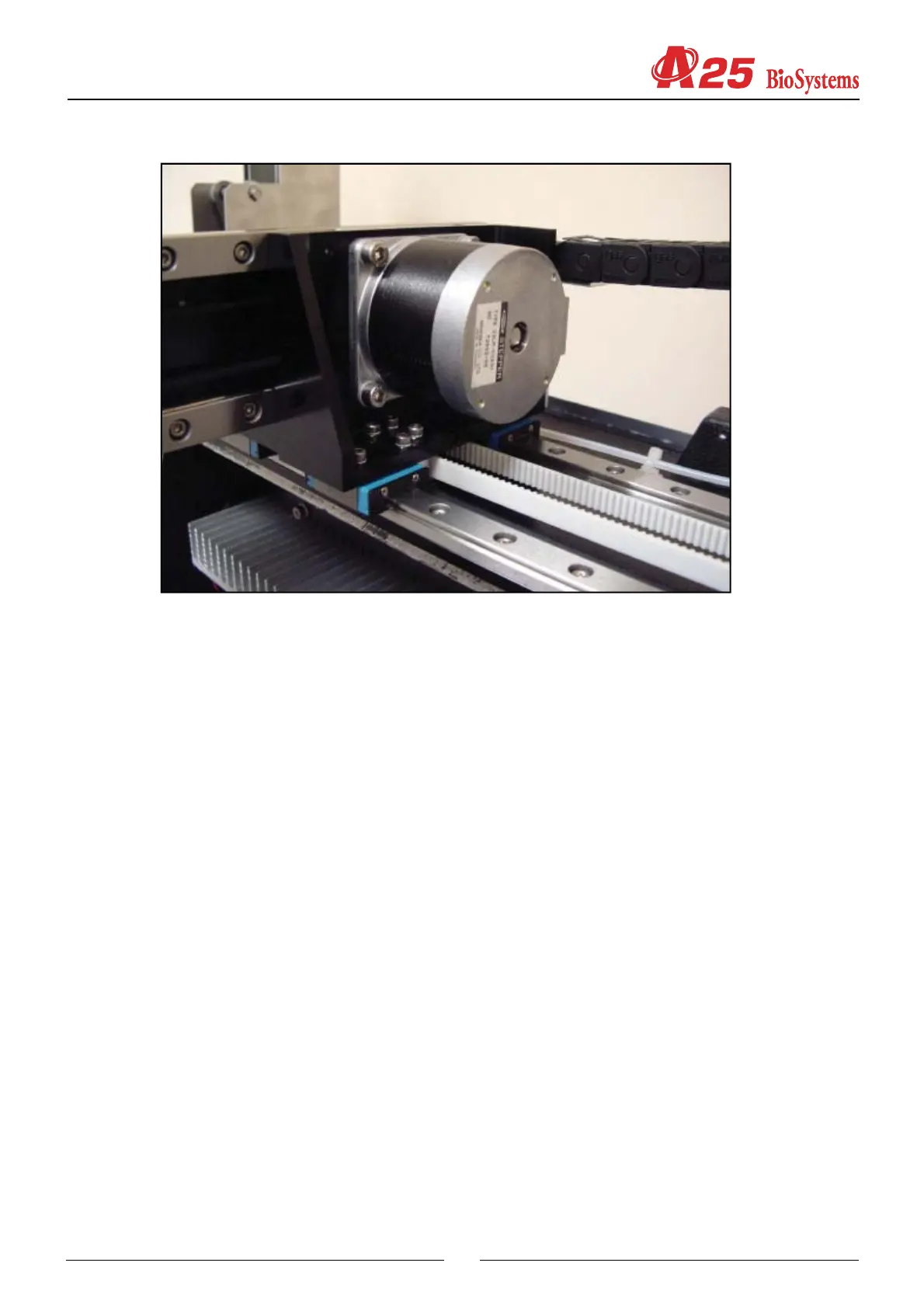

n) Turn the spring 1 and half turns (360 º + 180 º) clockwise using the slot at the back of the encoder. Use a M4x25 screw

to block the spring in the desired position. This screw must be introduced in the threaded hole of the support body for

this purpose as shown in the photograph.

o) Place the Z carriage in the top position of its run and fit the belt on the upper return pulley and on the motor pulley.

p) Loosen the screw that blocks the spring (if it has been used) and tighten the belt by displacing the motor downwards.

Tighten the 4 screws on the front and the 2 on the back, which hold the unit together.

q) Do the motor test with the service program

Loading...

Loading...