113

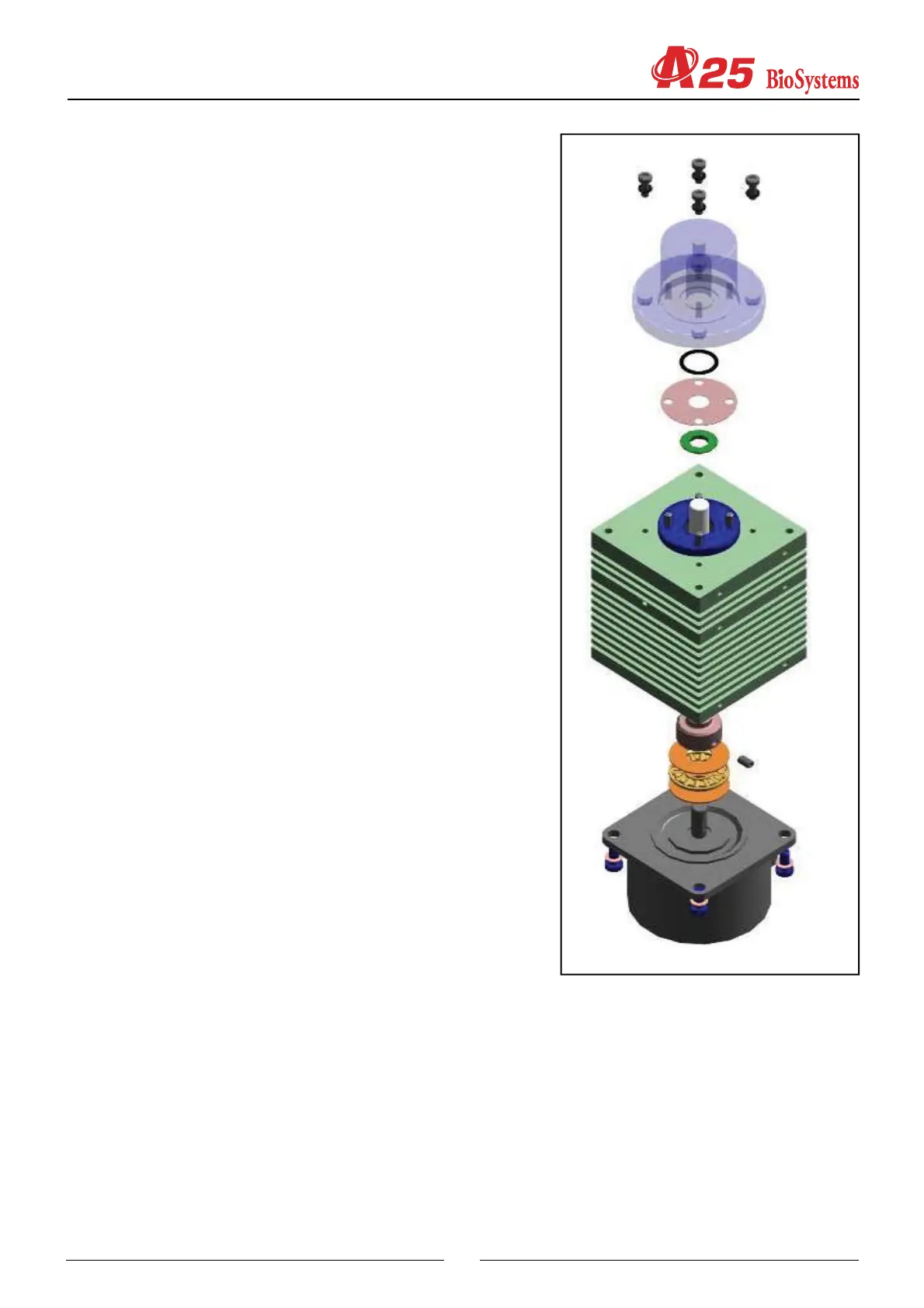

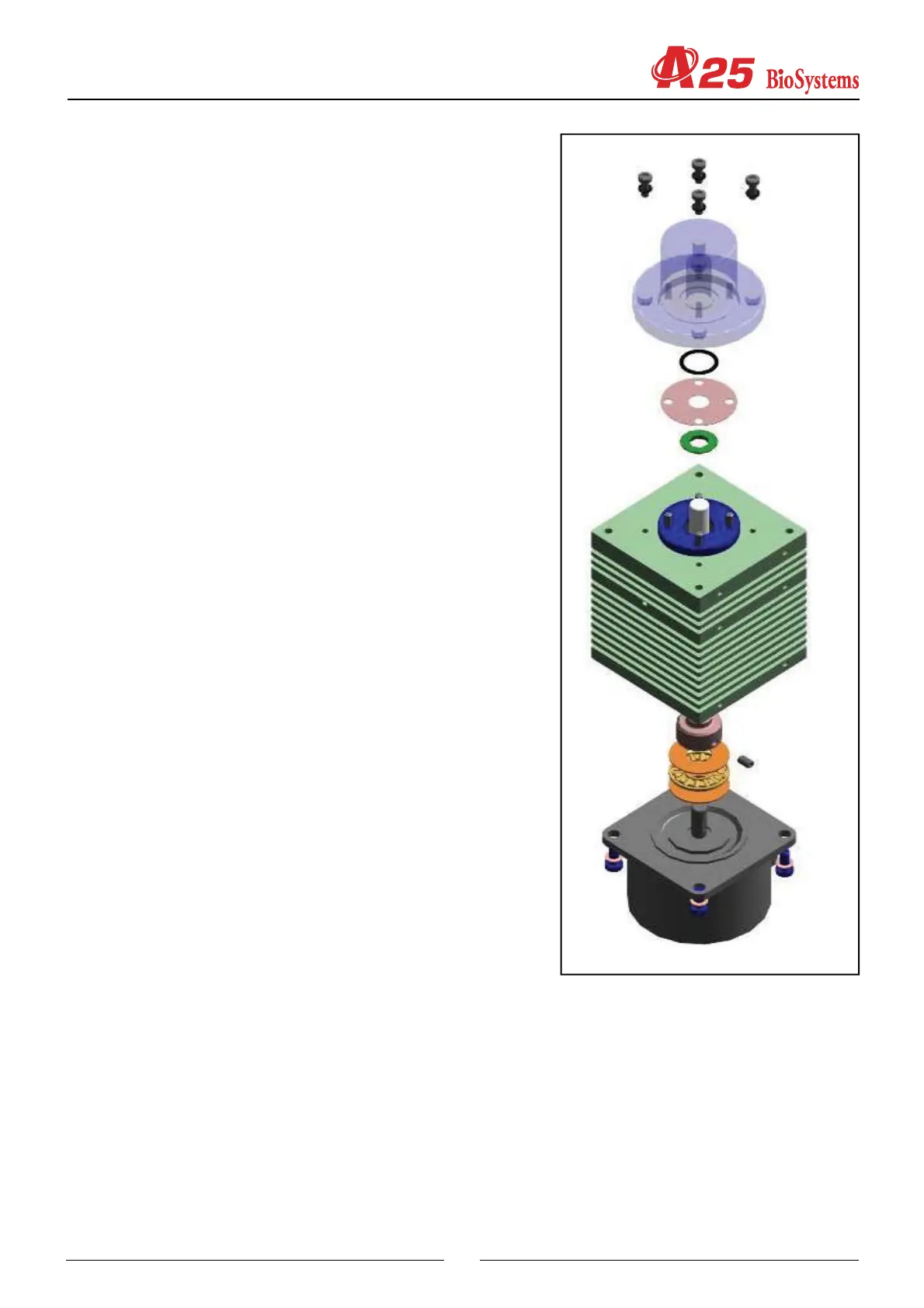

5.1.3.7. Changing the dispensing pump motor

a) Remove the dispensing pump.

b) Remove the motor by removing the corresponding screws.

c) Unscrew the ceramic piston support. Handle with great

care.

d) Loosen the Allen bolt and remove the stud and the axial

bearing.

e) Fit the axial bearing and the stud on the new motor. The

Allen bolt must coincide with the machined surface of the

motor shaft.

f) Remove the fluidic chamber to access the ring seal and

the plastic disc.

g) Clean off the used grease. Put new grease on the stud and

on the piston support.

h) Fit the motor with the stud and the piston support on the

pump body.

i) Clean the piston if it has been stained with lubricant grease.

j) Fit the plastic disc and the ring seal on the ceramic piston

as shown in the diagram. See the assembly position of the

disc.

k) Refit the fluidic chamber in the pump.

5.1.3.8. Changing the dispensing electrovalve

a) Remove the dispensing pump.

b) Disconnect the fittings and the electrical connector.

c) Remove the screws that hold the electrovalve in position. Access to these screws is easier if the dispensing pump is

removed.

d) Fit the new electrovalve. Do not tighten the screws to excess so as not to deform the plastic body of the electrovalve

and damage its leakproof quality.

Loading...

Loading...